Top Manufacturers of Metal Roll Forming Systems for Efficient Production

Metal Roll Forming Systems Manufacturers Evolution and Benefits

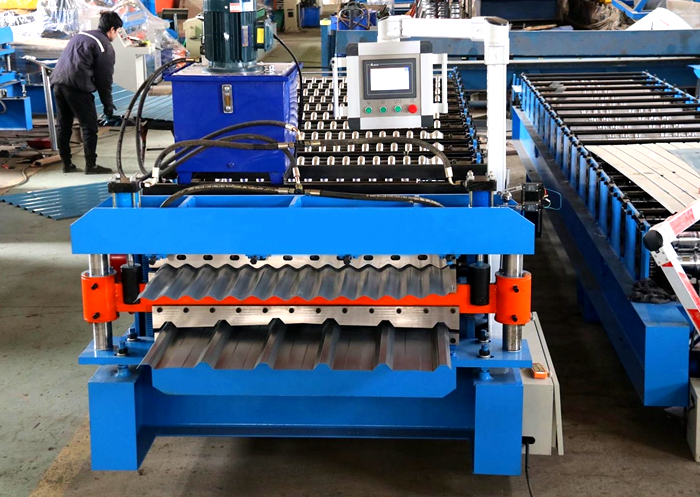

In the competitive landscape of manufacturing, the importance of efficiency and precision cannot be overstated. One of the core technologies that has revolutionized metal processing is the roll forming system. This manufacturing method has seen significant advancements in recent years thanks to innovative metal roll forming systems manufacturers. This article will delve into the evolution of these systems, their applications, and the notable benefits they bring to various industries.

Understanding Roll Forming

Roll forming is a continuous bending operation in which a long strip of metal, usually steel or aluminum, is fed through a series of rolls that progressively shape the material into a desired cross-section. The process is notably efficient for producing complex shapes with consistent dimensions over large lengths, making it ideal for high-volume production.

Evolution of Metal Roll Forming Systems

Historically, roll forming systems were simple in design, limited to basic shapes and slower production speeds. However, the advent of advanced technologies such as Computer Numerical Control (CNC) and automation has transformed this field. Modern metal roll forming systems are now equipped with intelligent control systems that enhance accuracy and reduce human error.

Manufacturers such as *Formtek*, *Roll-Kraft*, and *BlueScope Steel* have played a crucial role in innovating roll forming technologies. These companies focus on developing systems that can handle varying thicknesses and types of metals while maintaining high-speed production rates. The integration of cutting-edge materials, such as advanced alloys and composites, has also expanded the range of applications for roll-formed products.

Applications Across Industries

The versatility of roll forming makes it applicable in multiple sectors. One of the most prominent applications is in the automotive industry, where roll-formed components are used for chassis, body frames, and various structural parts. The aerospace sector also benefits, utilizing roll forming for components that combine high strength with low weight.

Construction is another major domain where roll-formed products shine. Steel framing, roofing panels, and commercial gutters are often produced using roll forming techniques, ensuring durability and reliability. Additionally, manufacturers in the appliance and HVAC sectors find roll forming to be an effective method for producing ducts, casing, and other essential components.

metal roll forming systems manufacturers

Benefits of Metal Roll Forming Systems

Metal roll forming systems offer a plethora of benefits that set them apart from other manufacturing processes

1. High Production Efficiency Roll forming is a continuous process, allowing for higher output rates. This is particularly beneficial for projects requiring large quantities of identical parts.

2. Consistency and Accuracy With automated and CNC-controlled forming systems, manufacturers achieve superior consistency and precision in their products. Each piece produced is uniform, reducing waste and the time spent on secondary processes.

3. Material Savings The roll forming process generates minimal scrap material compared to methods like stamping. Manufacturers can maximize material usage, leading to cost savings and increased sustainability.

4. Design Flexibility Modern roll forming systems can create complex shapes and profiles, enabling innovative designs that meet specific requirements. Custom tooling options further enhance this flexibility.

5. Reduced Labor Costs Automation in roll forming reduces manual labor requirements, allowing manufacturers to allocate human resources to higher-value tasks. This leads to increased overall productivity.

6. Durability Roll-formed products tend to exhibit high strength and durability, making them ideal for rigorous applications. The process also allows for the use of various coatings to enhance corrosion resistance.

Conclusion

As the manufacturing landscape continues to evolve, metal roll forming systems manufacturers are at the forefront of innovation, providing cutting-edge solutions to meet the demands of various industries. With their enhanced efficiency, precision, and flexibility, these systems represent the future of metal processing. Companies striving to remain competitive would do well to invest in advanced roll forming technology, positioning themselves for success in an ever-changing market. The collaboration between manufacturers and technology will undoubtedly yield even more advancements in roll forming processes in the years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025