Metal Roll Forming Machines for Sale from Leading Manufacturers and Suppliers Worldwide

Metal Roll Forming Machines for Sale A Comprehensive Guide

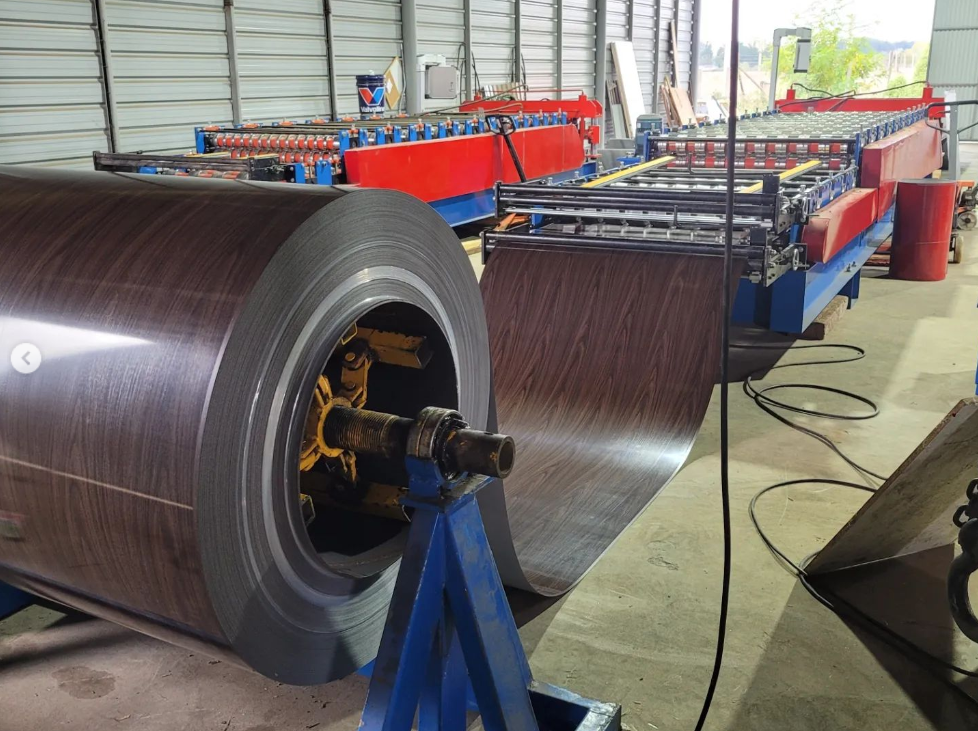

In the realm of manufacturing, efficiency, precision, and adaptability are key factors driving success. Among the equipment that embodies these qualities are metal roll forming machines. These advanced machines have become indispensable in producing a wide array of products, from metal roofing systems to complex structural components. If you are in the market for metal roll forming machines for sale, understanding their functionality, benefits, and the factors to consider will help you make an informed decision.

What is Metal Roll Forming?

Metal roll forming is a manufacturing process that involves feeding a long strip of metal through a series of rollers that progressively shape the material into a desired cross-section. This continuous process allows for the production of complex shapes and profiles at high speeds, making it a cost-effective option for mass production. The materials commonly used in roll forming include steel, aluminum, and stainless steel, which can be produced in various thicknesses and finishes.

Advantages of Metal Roll Forming Machines

1. High Efficiency Roll forming machines are designed for continuous operation, which enhances productivity. Once set up, these machines can produce thousands of linear feet of product per hour.

2. Consistency and Precision The automated nature of roll forming ensures that each piece produced maintains uniform dimensions and quality. This precision is crucial in industries where exact specifications are paramount.

3. Material Savings Roll forming minimizes waste by producing shapes with minimal scrap material. The efficient use of raw materials contributes to lower production costs.

4. Versatility Roll forming machines can be customized to produce a wide range of products, from simple shapes to complex configurations. This versatility allows manufacturers to adapt to changing market demands and customer requirements.

5. Durability Investing in a high-quality roll forming machine can yield long-term returns, as these machines are built to last. They require less maintenance compared to many other manufacturing processes.

metal roll forming machines for sale companies

Factors to Consider When Purchasing Roll Forming Machines

When searching for roll forming machines for sale, several factors should be taken into account

1. Nature of Production Determine the specific types of products you will be manufacturing. This will guide you in selecting a machine with the appropriate specifications and capabilities.

2. Material Compatibility Ensure that the roll forming machine can handle the materials you intend to use, considering factors like thickness, material type, and surface finish.

3. Machine Size and Configuration Consider the available space in your facility, as well as the dimensions and weight of the machine. Additionally, evaluate whether a standard machine meets your needs or if a custom design is required.

4. Automation and Control Systems Modern roll forming machines often come equipped with advanced automation features, including programmable controls and real-time monitoring systems. These features can enhance efficiency and reduce operating errors.

5. Supplier Reputation and Support Choose a reputable supplier who offers comprehensive support, including installation, training, and after-sales service. A good relationship with the supplier can contribute significantly to the success of your operations.

Conclusion

Metal roll forming machines represent a vital investment for manufacturers looking to streamline production and enhance product quality. With their numerous advantages, these machines can significantly contribute to the profitability of a business. As you explore options for metal roll forming machines for sale, ensure that you consider the specific needs of your production processes and partner with a reliable supplier to maximize your investment. By doing so, you will be well-equipped to meet the demands of the market while achieving operational excellence.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025