metal roll forming machine manufacturers

Understanding Metal Roll Forming Machine Manufacturers

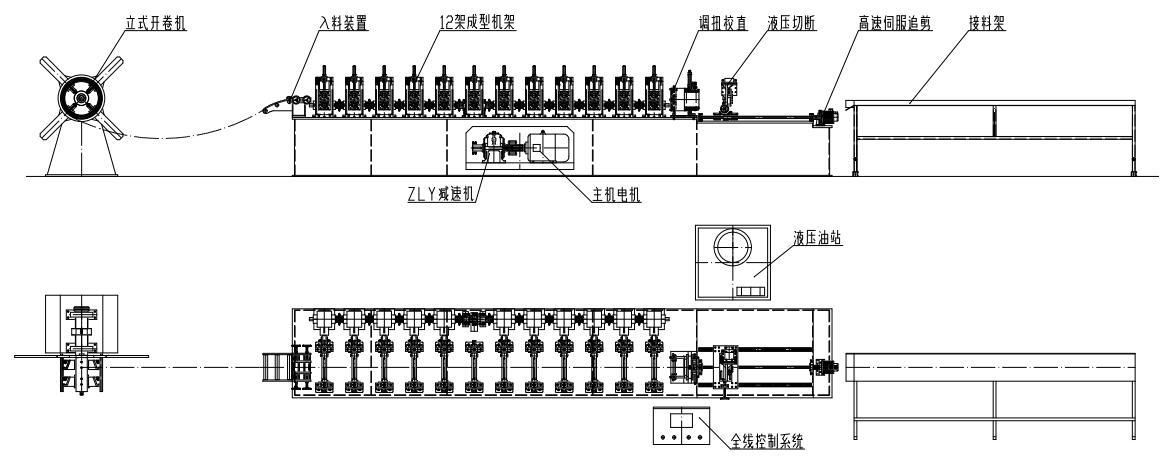

In the realm of metal fabrication, one of the most significant innovations is the metal roll forming machine. This technology shapes metal into desired profiles through a series of rolls, offering precision, efficiency, and versatility that is unmatched in the manufacturing process. As industries evolve, so does the demand for high-quality roll forming equipment. This article explores the landscape of metal roll forming machine manufacturers, highlighting their contributions, challenges, and the future trends in this dynamic sector.

The Role of Metal Roll Forming Machines

Metal roll forming machines are utilized to produce a variety of products—from roofing sheets and metal studs to custom profiles for various constructions and automotive applications. The process involves feeding a metal strip through a series of rollers, each shaping it further until the final profile is achieved. This method is favored for its ability to create long lengths of uniform products with minimal waste.

Key Manufacturers in the Industry

The market for metal roll forming machines is diverse, with numerous manufacturers providing a range of products and services. Some key players in the industry include

1. Tensile Forming Solutions Known for their high-quality and customizable machinery, Tensile Forming Solutions has established itself as a leader. They focus on customer specifications and offer support for automation integration, ensuring efficiency and precision.

2. RollForming Corporation This company specializes in advanced roll forming solutions with a range of machines suited for different applications. Their commitment to innovation keeps them at the forefront, offering automated machines that improve production speed and reduce operational costs.

3. Formtek A veteran in the field, Formtek provides a wide array of roll forming machines, tooling, and engineering support. Their focus on technology enables manufacturers to stay competitive by improving product quality while minimizing downtime.

These manufacturers have built reputations not merely on the machines they produce but also on the customer service and support they provide, which is vital for companies investing in such capital equipment.

Challenges Faced by Manufacturers

metal roll forming machine manufacturers

While the demand for roll forming machines is increasing, manufacturers face several challenges in the industry. One of the primary hurdles is the continuous need for innovation. As customer needs evolve, manufacturers must consistently adapt their machines to handle new materials, profiles, and production processes.

Additionally, competition in the global market has intensified. Many manufacturers are vying for the same customer base, which has led to pressure on pricing and profit margins. This environment necessitates a focus on quality and after-sales support, as these aspects can significantly influence purchasing decisions.

Labor shortages also pose challenges, particularly in regions where manufacturing is a key driver of the economy. Finding skilled workers who can operate and maintain sophisticated machinery is becoming increasingly difficult. As a response, companies are investing in training programs and automation technologies to mitigate these issues.

Future Trends in Metal Roll Forming

Looking ahead, several trends are poised to shape the future of metal roll forming manufacturers

1. Automation and Smart Manufacturing The integration of automation and Industry 4.0 technologies is making machines smarter, allowing for real-time monitoring and data collection, which can improve efficiency and reduce waste significantly.

2. Sustainability As industries become more environmentally conscious, manufacturers are finding ways to produce machines that consume less energy and produce less waste. This trend is likely to continue as regulations around sustainability tighten.

3. Customization The demand for personalized solutions is on the rise. Manufacturers that can offer flexible and customized roll forming solutions will likely gain a competitive edge in the market.

4. Material Innovation New materials and composites are emerging, and manufacturers that can adapt their machines to handle these materials will be well-positioned for future growth.

In conclusion, metal roll forming machine manufacturers play a crucial role in the advancement of metal fabrication technologies. By addressing current challenges and embracing future trends, these manufacturers are set to lead the way in a continually evolving industry. For businesses looking to enhance their manufacturing capabilities, partnering with the right roll forming machine manufacturer could be the key to staying competitive and meeting consumer demands in the years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025