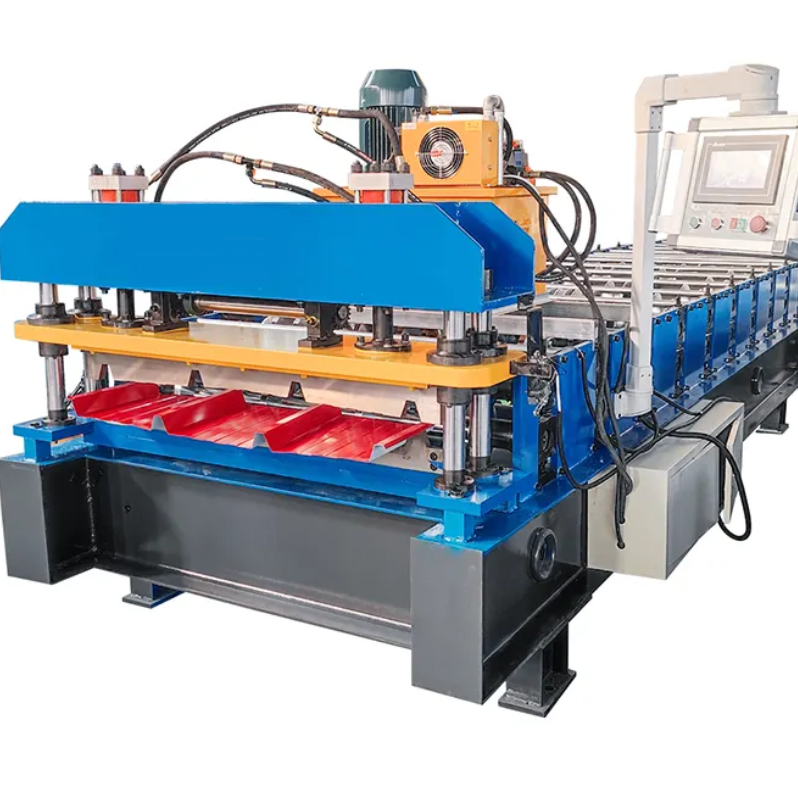

metal roll forming machine for sale factories

Metal Roll Forming Machines A Comprehensive Overview for Buyers

In the modern manufacturing landscape, efficient and cost-effective solutions are vital for keeping up with the increasing demand for quality metal products. One such solution is the metal roll forming machine, a piece of equipment that has gained significant traction in various industries. This article will delve into the features, benefits, and considerations when looking for a metal roll forming machine for sale, particularly from reputable factories.

What is a Metal Roll Forming Machine?

A metal roll forming machine is a type of equipment used to create shapes and profiles from metal sheets. The process involves continuously feeding a metal strip through a series of rollers that gradually shape the material into the desired profile. The end result is a product that is both strong and lightweight, ideal for applications in construction, automotive, appliance manufacturing, and more.

Advantages of Using Roll Forming Machines

1. High Production Efficiency Metal roll forming machines are designed for mass production. Once set up, they can operate continuously, producing thousands of feet of product per day with minimal manual intervention.

2. Consistency and Precision These machines provide high levels of accuracy and repeatability. As the same set of rollers is used to shape the material, the dimensions of the finished product remain consistent, which is essential for industries requiring precise specifications.

3. Material Versatility Roll forming can be applied to a wide range of materials, including steel, aluminum, and copper. This flexibility makes these machines a popular choice among manufacturers who work with diverse metal types.

4. Reduced Waste The roll forming process is highly efficient, resulting in minimal waste material compared to other methods. Additionally, the continuous nature of the process maximizes the use of raw materials.

5. Customizability Many manufacturers offer metal roll forming machines that can be customized to meet specific production requirements. Buyers can request tailored designs that suit their unique applications, ensuring optimum performance.

Key Features to Consider

When looking for metal roll forming machines for sale, it is crucial to consider several key features

metal roll forming machine for sale factories

- Machine Size and Capacity Depending on the production scale and space available, buyers should determine the appropriate size and capacity for their specific needs.

- Roller Material and Design The material and design of the rollers significantly impact the machine's performance and longevity. Ensure that the rollers are made from durable materials to withstand continuous use.

- Control Systems Advanced control systems offer better precision and ease of use. Look for machines with digital displays and programmable settings, which can simplify operations and reduce the likelihood of errors.

- Safety Features Given the nature of metal forming, safety should be a priority. Ensure that the machine includes features such as emergency stop buttons, safety guards, and overload protection.

Choosing the Right Factory

When searching for a metal roll forming machine for sale, it’s essential to partner with a reputable factory. Here are a few tips to find the right one

- Research Manufacturer Reputation Look for factories with a proven track record in the industry. Customer reviews and testimonials can provide insight into the quality and reliability of the machines.

- Request Demonstrations Whenever possible, ask for demonstrations of the machine in action. This will help you assess the quality of the product and the performance of the machine.

- Check After-Sales Support A reliable factory should offer good after-sales support, including maintenance services, training for operators, and availability of spare parts.

- Compare Pricing While cost is an important factor, it should not be the sole criterion. Compare the features and quality offered by different manufacturers to ensure you are getting the best value for your investment.

Conclusion

Investing in a metal roll forming machine can significantly enhance your production capabilities, allowing for increased efficiency and product quality. By considering the features discussed and choosing a reputable factory, businesses can ensure they acquire a machine that meets their specific needs and enables them to thrive in a competitive market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025