Top Manufacturers of Metal Roll Forming Machines Worldwide

Exploring Metal Roll Forming Machine Factories A Key to Precision Manufacturing

In the world of manufacturing, efficiency, precision, and innovation are paramount. Among the various processes that cater to these needs, metal roll forming stands out as a crucial technology that serves multiple industries, from automotive to construction. At the heart of this process lie the metal roll forming machine factories, where advanced technology and skilled craftsmanship converge to produce an array of metal profiles that are essential in modern manufacturing.

What is Metal Roll Forming?

Metal roll forming is a continuous bending operation in which a long strip of metal is passed through a series of rollers, converting it into specific shapes or profiles. This technique allows for the mass production of complex shapes with exceptional accuracy, minimal waste, and high efficiency. The products of this process are ubiquitous—from the roof panels of a building to components within vehicles, making it a vital segment of the manufacturing landscape.

The Role of Metal Roll Forming Machine Factories

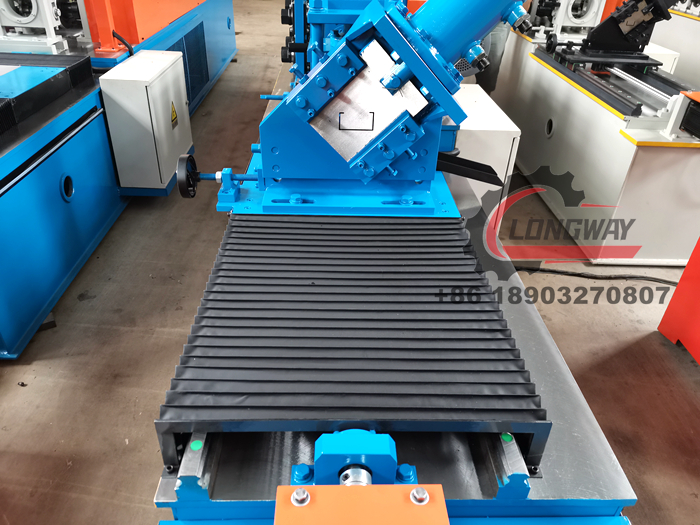

Metal roll forming machine factories play a critical role in the production chain. These factories design and manufacture machines that create the rolling equipment integral to the roll forming process. The factories are equipped with state-of-the-art technology, encompassing everything from computer-aided design (CAD) systems for precision engineering to high-performance hydraulic systems that ensure optimal output.

1. Innovation and Development Continuous innovation is vital in keeping pace with the evolving demands of various industries. Factory engineers and technicians work closely to develop more efficient roll forming machines that can handle a range of materials—from mild steel to aluminum and stainless steel—without compromising quality. Research and development teams are focused on enhancing machine automation, reducing energy consumption, and increasing production speed.

2. Customization Every client has unique specifications based on their application needs. Metal roll forming machine factories excel in offering customized solutions that fit a client's specific requirements. This includes bespoke tooling, tailored machine configurations, and specialized materials that cater to diverse manufacturing needs. Such custom solutions significantly enhance productivity while ensuring the end products meet all quality standards.

metal roll forming machine factories

3. Quality Control Quality assurance is a significant aspect of operations in metal roll forming machine factories. Rigorous testing procedures are in place to ensure that every machine produced meets industry standards and client specifications. This includes testing for structural integrity, precision in forming processes, and durability under various conditions. By maintaining high standards, factories ensure that their machines deliver reliable performance throughout their operational lifespan.

Global Market Dynamics

The demand for metal roll forming machinery is increasing globally, spurred by growth in the automotive, construction, and manufacturing sectors. As businesses seek more efficient and sustainable practices, metal roll forming machines are emerging as key contributors to achieving these goals. Factories around the world are responding to this demand by expanding their production capabilities and leveraging advanced technologies such as Industry 4.0, which integrates automation and data exchange in manufacturing technologies.

Sustainability in Manufacturing

Sustainability is at the forefront of modern manufacturing practices. Metal roll forming is inherently a material-efficient process, producing less waste compared to traditional cutting and machining methods. Metal roll forming machine factories are increasingly focusing on sustainable practices by using recyclable materials and energy-efficient technologies. These efforts not only help reduce the environmental impact but also lower operational costs, making them more appealing to manufacturers committed to sustainability.

Conclusion

Metal roll forming machine factories are integral to the future of manufacturing, driving innovation, efficiency, and quality. As industries continue to evolve, these factories are well-positioned to meet the growing demands for precision-engineered metal products. By investing in advanced technologies and sustainable practices, they are not just shaping metal; they are shaping the future of manufacturing itself. It is evident that the role of these factories extends beyond production; they are catalysts for change and innovation within the global marketplace.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025