Jan . 25, 2025 21:12

Back to list

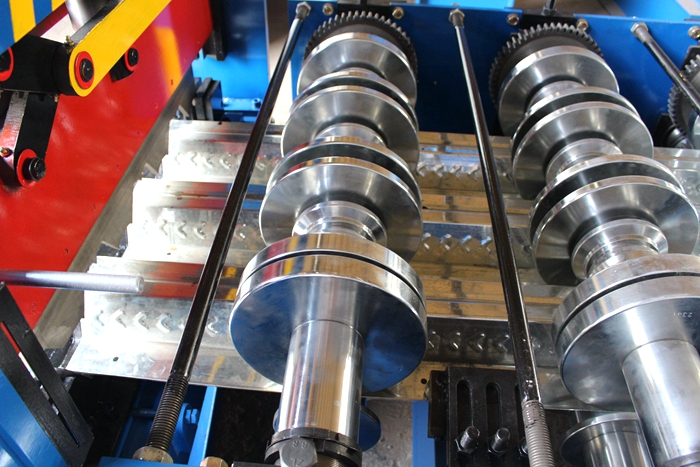

metal roll forming companies

Metal roll forming companies are pivotal in manufacturing processes, providing cost-effective and efficient solutions for creating complex shapes and profiles from sheet metal. The unique capability of roll forming to handle intricate designs makes these companies indispensable partners for industries such as automotive, construction, and aerospace. Recognizing the true value of these companies requires a deeper understanding of their expertise, technological advancements, and commitment to quality and innovation.

Renowned roll forming companies demonstrate authoritativeness by setting industry standards and serving as thought leaders. Their dedication to research and development not only fosters innovation but also positions them at the forefront of new manufacturing trends. Companies often engage in collaborations with universities and research institutions, contributing to the development of new alloys and sustainable practices that enhance the environmental footprint of metal forming. By publishing findings and contributing to industry forums, these companies assert their authority and share valuable insights into best practices and emerging technologies. Trustworthiness is paramount in selecting a metal roll forming partner. Companies earn this trust through consistent delivery of high-quality products and by adhering to stringent quality control measures. Certifications from recognized industry bodies further bolster customer confidence, assuring compliance with international standards. Transparent business practices, such as clear communication of production timelines and pricing structures, reinforce reliability and foster long-standing business relationships. Consumers seeking roll forming services should prioritize companies that exhibit these qualities. The right partner will not only provide expert solutions at a competitive edge but will also collaborate closely with clients throughout the design and production stages, ensuring the final product truly aligns with the envisioned project goals. By focusing on companies that embody experience, expertise, authoritativeness, and trustworthiness, businesses can capitalize on the remarkable benefits of metal roll forming, leading to innovations that transcend traditional manufacturing boundaries.

Renowned roll forming companies demonstrate authoritativeness by setting industry standards and serving as thought leaders. Their dedication to research and development not only fosters innovation but also positions them at the forefront of new manufacturing trends. Companies often engage in collaborations with universities and research institutions, contributing to the development of new alloys and sustainable practices that enhance the environmental footprint of metal forming. By publishing findings and contributing to industry forums, these companies assert their authority and share valuable insights into best practices and emerging technologies. Trustworthiness is paramount in selecting a metal roll forming partner. Companies earn this trust through consistent delivery of high-quality products and by adhering to stringent quality control measures. Certifications from recognized industry bodies further bolster customer confidence, assuring compliance with international standards. Transparent business practices, such as clear communication of production timelines and pricing structures, reinforce reliability and foster long-standing business relationships. Consumers seeking roll forming services should prioritize companies that exhibit these qualities. The right partner will not only provide expert solutions at a competitive edge but will also collaborate closely with clients throughout the design and production stages, ensuring the final product truly aligns with the envisioned project goals. By focusing on companies that embody experience, expertise, authoritativeness, and trustworthiness, businesses can capitalize on the remarkable benefits of metal roll forming, leading to innovations that transcend traditional manufacturing boundaries.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products