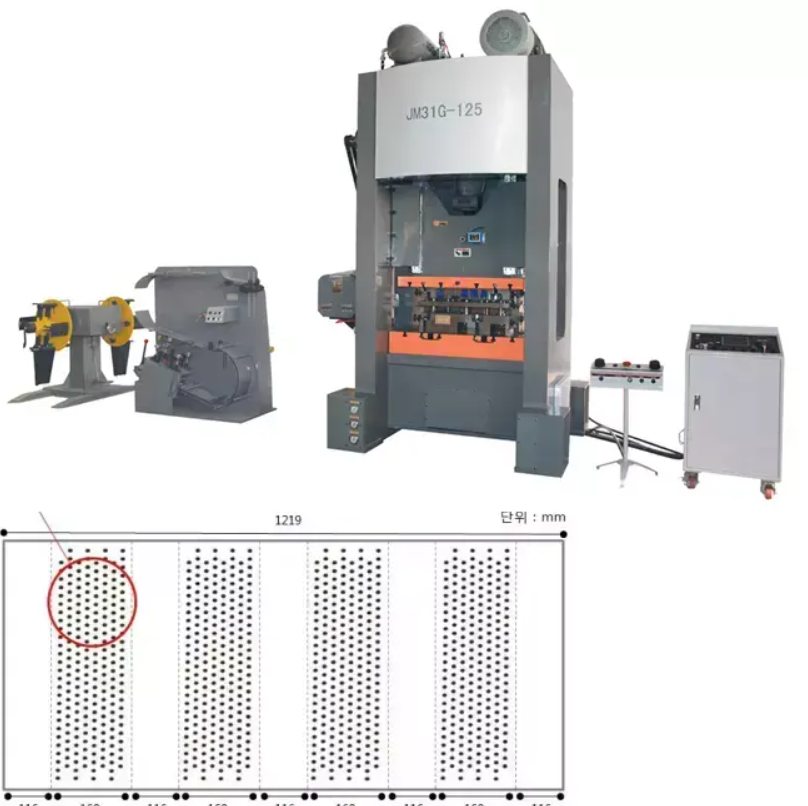

metal panel machine for sale manufacturer

Exploring the Benefits of Metal Panel Machines for Sale

In the modern industrial landscape, efficiency and precision are paramount. Among the myriad of machines that have emerged to cater to this need, metal panel machines stand out, offering unmatched capabilities for manufacturing metal panels used in various applications, including construction, automotive industries, and more. This article delves into the significance of metal panel machines, highlighting their functionality, the advantages of investing in such equipment, and points to consider when looking for a manufacturer.

Understanding Metal Panel Machines

Metal panel machines are specialized equipment designed to produce metal panels efficiently and accurately. These machines come in various forms, including roll forming machines, shearing machines, and panel bending machines, each tailored for specific panel designs and applications. Typically, they can process a variety of materials, including aluminum, steel, and stainless steel, making them versatile tools in any manufacturing facility.

The primary function of these machines is to create panels that meet stringent standards for aesthetics, durability, and performance. Whether for roofing, siding, or wall applications, these machines ensure that the finished products exhibit the desired qualities essential in today’s competitive markets.

The Advantages of Investing in Metal Panel Machines

1. Increased Production Efficiency One of the significant benefits of utilizing metal panel machines is the substantial increase in production rates. Automated processes reduce manual intervention, allowing for higher throughput. This efficiency becomes particularly crucial during peak production cycles where meeting tight deadlines is a must.

2. Cost-Effectiveness While the initial investment in metal panel machines may be considerable, the long-term savings are substantial. Automation reduces labor costs and minimizes material waste through precise cutting and shaping. As a result, facilities can achieve higher profit margins over time.

3. Quality Control Metal panel machines are designed with precision in mind. They consistently produce panels with exact specifications, significantly reducing the chances of defects. This level of accuracy ensures that businesses maintain a high standard of quality in their products, which can lead to increased customer satisfaction and loyalty.

4. Customization Options Many modern metal panel machines offer customizable features, allowing manufacturers to create unique designs tailored to specific client needs. This versatility enables businesses to cater to niche markets and diversify their product offerings, which can open new avenues for revenue.

metal panel machine for sale manufacturer

5. Durability and Longevity Investing in high-quality metal panel machines means accessing robust equipment that can withstand the rigors of constant use. Reputable manufacturers ensure that their machines are built with durable materials and innovative technology, thus promising a longer service life with minimal maintenance.

Choosing the Right Manufacturer

When selecting a manufacturer for metal panel machines, several factors must be taken into consideration

- Reputation and Experience Look for companies with a proven track record in the industry. Established manufacturers often have years of experience and a wide range of satisfied customers.

- Product Range Assess the variety of machines offered. A manufacturer that offers a diverse range of models can cater to various production needs, allowing for future scalability.

- Technical Support and Services Ensure that the manufacturer provides excellent customer support and after-sales services. This can be crucial in minimizing downtime and addressing any operational issues promptly.

- Quality Assurance Always inquire about the quality control measures that the manufacturer implements to ensure that their machines meet industry standards.

- Warranty and Guarantees A reliable manufacturer will offer warranties on their equipment, providing peace of mind regarding the quality and longevity of the machinery.

Conclusion

The rise of metal panel machines in the manufacturing sector represents a significant leap towards efficiency and innovation. By understanding their advantages and learning how to choose the right manufacturer, businesses can position themselves to capitalize on the benefits these machines offer. Ultimately, investing in quality metal panel machines can lead to improved production capabilities, reduced costs, and enhanced product quality, thereby ensuring a competitive edge in today’s fast-paced marketplace.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025