metal panel machine for sale companies

Exploring Metal Panel Machines for Sale A Comprehensive Guide

In today's rapidly evolving manufacturing landscape, the demand for high-quality metal panel machines has surged. These machines play a crucial role in the production of various metal sheeting products used in construction, automotive, and appliance industries. This article delves into the features, benefits, and considerations when seeking metal panel machines for sale, providing insights for potential buyers looking to invest in this essential technology.

Understanding Metal Panel Machines

Metal panel machines are specialized equipment designed to manufacture metal panels that can be used for a wide range of applications. From wall cladding to roofing materials and decorative elements, these machines are essential in producing durable and visually appealing metal products. The technology behind these machines often includes advanced automation, CNC (Computer Numerical Control), and varying forming techniques to achieve precision and efficiency.

Types of Metal Panel Machines

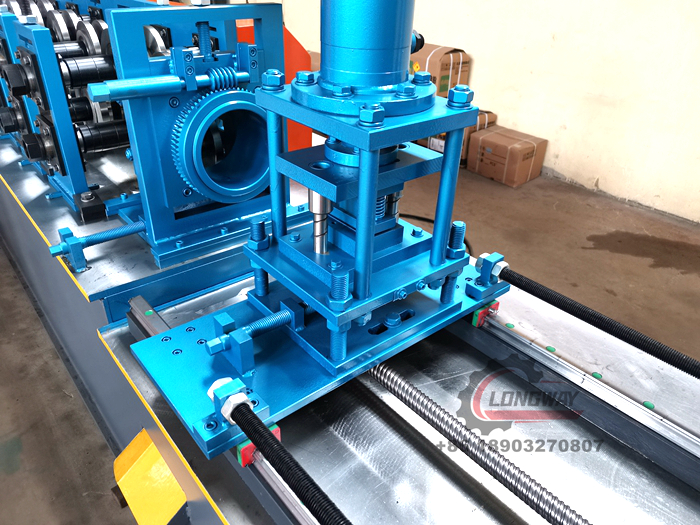

1. Roll Forming Machines These are perhaps the most commonly used metal panel machines. They operate by feeding metal sheets through a series of rollers, which gradually shape the sheet into the desired profile. Roll forming is particularly advantageous for producing long lengths of material with consistent quality.

2. Stamping Machines Stamping is used when specific shapes or patterns are required. This machine presses sheets of metal into dies to create intricate designs, often employed in architectural applications or automotive parts.

3. Laser Cutting Machines For projects demanding high precision, laser cutting machines offer an effective solution. They use focused laser beams to cut through metal sheets with incredible accuracy, making them ideal for intricate designs or customized orders.

4. Shearing Machines These machines are essential for cutting metal sheets to desired dimensions before further processing. Shearing is a straightforward and efficient method that ensures clean cuts without generating excessive scrap material.

Benefits of Investing in Metal Panel Machines

- Increased Production Efficiency Modern metal panel machines are designed for speed and efficiency

. With automation capabilities, they can operate continuously, significantly increasing output while reducing labor costs.metal panel machine for sale companies

- Enhanced Accuracy and Precision Advanced technologies such as CNC ensure that manufactured panels meet exact specifications, minimizing waste and rework, which can be costly in the long run.

- Versatility Many metal panel machines can handle various materials, including aluminum, steel, and copper, making them suitable for diverse applications.

- Durability and Reliability High-quality metal panel machines are built to withstand heavy use, providing reliable performance over extended periods, which is crucial for maintaining production schedules.

Considerations When Purchasing

When looking for metal panel machines for sale, several key factors should be considered

1. Machine Specifications Assess the technical requirements of your projects and ensure the machine's capabilities align with your production needs.

2. Vendor Reputation Research the manufacturers or suppliers of the machines. Established companies with a good track record are likely to provide better service, support, and quality.

3. Maintenance and Support Ensure that there is adequate customer support and availability of spare parts. Regular maintenance of machines is critical to ensure longevity and avoid downtime.

4. Cost vs. Value While it is tempting to opt for the cheapest option, considering the value, such as energy efficiency, warranty, and longevity, is essential in making a sound investment.

Conclusion

Investing in a metal panel machine is a significant decision that can impact your manufacturing capabilities for years to come. By understanding the types of machines available, their benefits, and the essential considerations when purchasing, you can make an informed choice that addresses your production needs. As the market evolves, staying updated on advancements in technology will help you leverage these machines to gain a competitive edge in your industry. Whether you are a small workshop or a large-scale manufacturer, the right metal panel machine can enhance your productivity and product quality, setting the foundation for success in your endeavors.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025