metal keel roll forming machine factory

Understanding Metal Keel Roll Forming Machines The Backbone of Modern Construction

In the ever-evolving world of construction, efficiency and precision are paramount. One of the indispensable tools that enhance these qualities is the metal keel roll forming machine. This advanced piece of equipment plays a critical role in the production of metal components used in a variety of applications, most notably in ceiling and wall systems. As buildings grow taller and architectural designs become more intricate, the need for reliable and cost-effective production methods is more important than ever.

What is a Metal Keel Roll Forming Machine?

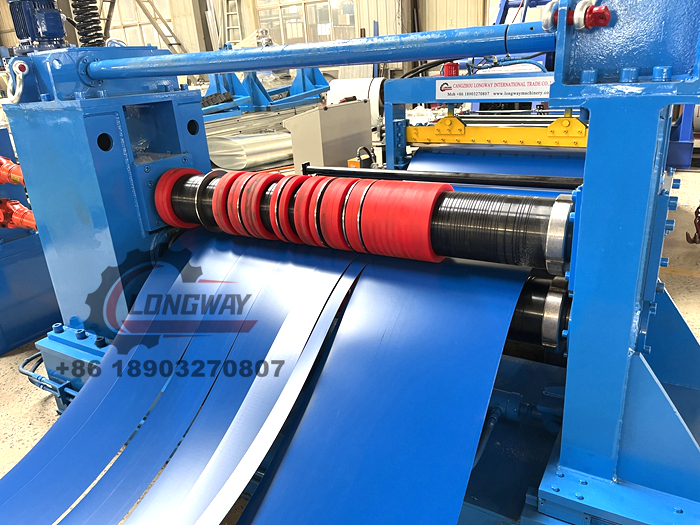

A metal keel roll forming machine is designed to produce metal keels, which are structural components typically used to support ceilings and walls. The machine works by continuously feeding metal sheets through a series of rollers that shape the material into the desired profile. This process, known as roll forming, allows for high-speed production of uniform and precise lengths of metal profiles.

These machines can accommodate a variety of materials, primarily including galvanized steel and aluminum, which are known for their durability and resistance to corrosion. The versatility of the metal keel roll forming machine makes it a valuable asset in the construction industry, where different projects may require different specifications and dimensions.

Key Features and Benefits

1. High Efficiency One of the main advantages of using a metal keel roll forming machine is its efficiency. The production process is continuous, allowing for high output with minimal manual intervention. This not only saves time but also reduces labor costs significantly.

2. Precision Engineering The roll forming process ensures that each metal keel produced is identical in dimensions, which is crucial for construction projects that demand uniformity for safety and aesthetic purposes. The precision inherent in the machine’s design minimizes waste and increases the quality of the end product.

3. Cost-Effectiveness With the ability to produce large quantities of metal keels in a short amount of time, companies can significantly reduce their production costs. The initial investment in machinery pays off through increased production rates and lower labor expenses.

4. Customizable Designs Modern metal keel roll forming machines can be tailored to produce specific profiles based on project needs. This flexibility allows manufacturers to meet the diverse requirements of their clients without the need for multiple machines.

metal keel roll forming machine factory

5. Durability and Strength The metal keels produced are robust and designed to withstand various environmental factors. Their strength supports the structural integrity of buildings, making them ideal for ceilings and partitioning systems.

The Manufacturing Process

The operation of a metal keel roll forming machine involves several stages

- Material Preparation Metal sheets are selected and cut to the appropriate size before entering the machine. - Roll Forming The sheets are fed into a series of specially designed rollers, which incrementally shape the metal into the desired profile. This process can produce different designs based on the setup of the rollers.

- Cutting and Finishing Once the metal has been formed, it is cut to the required lengths. Additional finishing processes may be applied, such as galvanization or painting, to enhance corrosion resistance and aesthetic appeal.

- Quality Control Each batch is rigorously tested to ensure it meets industry standards, ensuring that every product delivered is of the highest quality.

The Future of Metal Keel Roll Forming Machines

As technology advances, the capabilities of metal keel roll forming machines are expanding. Innovations such as automated production lines, enhanced monitoring systems, and energy-efficient designs are becoming increasingly common. Furthermore, the integration of smart technologies, like AI and IoT, is expected to revolutionize machine operation, enabling real-time data analysis and predictive maintenance.

In conclusion, metal keel roll forming machines are essential to modern construction, providing manufacturers with the tools they need to produce high-quality, cost-effective products. As the industry moves forward, these machines will continue to evolve, ensuring that they meet the demanding challenges of future construction projects. Investing in the latest technology not only enhances productivity but also propels the entire construction sector towards a more sustainable and efficient future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025