Metal Galvanized Floor Deck Roll Forming Machine for Efficient Construction Solutions

The Advancements in Metal Galvanized Panel Floor Deck Roll Forming Machines

In recent years, the construction industry has undergone significant transformations, thanks primarily to technological advancements. Among the many innovations that have facilitated these changes is the metal galvanized panel floor deck roll forming machine. This machine plays a crucial role in the production of high-quality floor decking materials capable of meeting modern construction standards.

Understanding Metal Galvanized Panels

Metal galvanized panels are sheets of steel that have been coated with zinc to protect against corrosion and enhance durability. This process involves the immersion of steel in molten zinc, forming a protective layer that significantly extends the material's lifespan. These panels offer various advantages, such as increased strength-to-weight ratio, improved fire resistance, and reduced maintenance costs, making them a preferred choice for flooring applications in commercial, industrial, and residential structures.

The Role of Roll Forming Machines

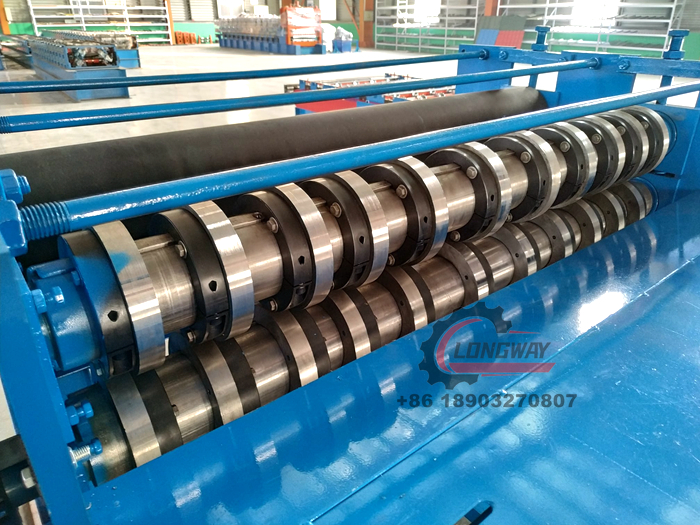

Roll forming machines are designed to transform flat metal coils into specific shapes and profiles. In the context of galvanized panel flooring, these machines continually feed steel strips through a series of rollers, shaping them into the desired configuration. The use of roll forming technology greatly streamlines the manufacturing process, leading to higher efficiency, reduced waste, and consistent quality in the final products.

The precision that roll forming machines provide ensures that every panel produced meets the required specifications, thus reducing installation times and enhancing structural integrity. Key features of these machines include adjustable roll forming stations, advanced control systems, and the capability to handle various material thicknesses, making them versatile for different production needs.

Key Features of Metal Galvanized Panel Floor Deck Roll Forming Machines

1. High Precision Advanced CNC technology allows for precise control over the dimensions and profiles of the panels produced. This precision is essential for creating panels that fit together seamlessly during installation.

metal galvanized panel floor deck roll forming machine

2. Speed and Efficiency These machines are capable of producing a high volume of floor deck panels in a short period, significantly increasing production rates. This efficiency reduces labor costs and shortens project timelines.

3. Durability and Strength The roll forming process enhances the strength of the panels, which are often used to support heavy loads in commercial buildings. The combination of galvanized steel and roll forming technology results in robust solutions for any construction project.

4. Adaptability Modern machines can be configured to produce various designs and profiles, allowing manufacturers to cater to diverse market demands. This flexibility is vital in today’s competitive market where customization is often required.

5. Automated Systems Many of these machines come with automated controls that reduce the need for manual intervention, minimizing the risk of errors and further enhancing production efficiency.

The Future of Construction with Roll Forming Technology

As the demand for sustainable and durable building materials continues to rise, the role of metal galvanized panel floor deck roll forming machines will undoubtedly be critical. These machines not only promote better resource management through efficient production but also align with the industry's move towards sustainable practices.

Additionally, with ongoing advancements in technology, we can expect future roll forming machines to be even more integrated with digital tools, enabling remote monitoring and maintenance. This will further enhance their efficiency and reliability.

In conclusion, metal galvanized panel floor deck roll forming machines are revolutionizing the construction landscape by providing high-quality, durable, and efficient flooring solutions. Their versatility and precision position them as an essential asset for manufacturers looking to meet the evolving demands of the construction industry. As technology continues to evolve, the potential for these machines and their impact on building practices is immense, ensuring that they remain at the forefront of construction innovation.

These advancements not only enhance operational capabilities but also contribute to building safer, more resilient infrastructure for future generations.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025