metal embossing press

Metal Embossing Press A Revolutionary Tool for Design and Production

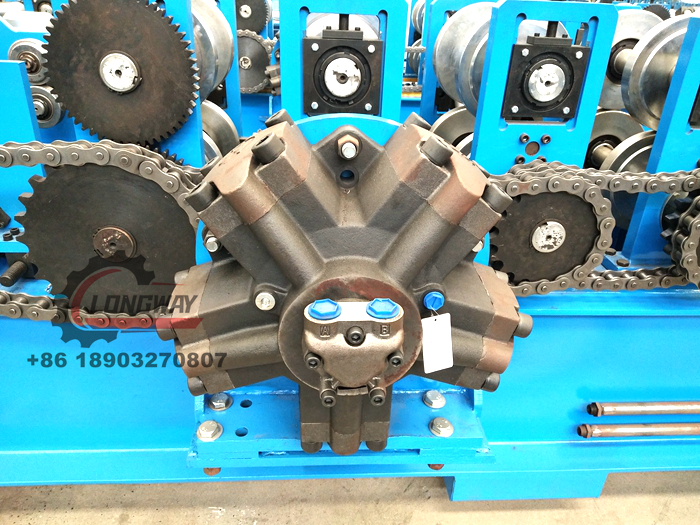

In the realm of manufacturing and decorative arts, the metal embossing press stands out as a revolutionary tool that combines functionality with aesthetic appeal. This machine plays a pivotal role in transforming plain metal sheets into exquisite designs, making it an essential asset for industries ranging from jewelry making to automotive components. By utilizing advanced technology and precise craftsmanship, metal embossing presses have enhanced production capabilities, provided cost-effective solutions, and encouraged creativity in design.

The Process of Metal Embossing

Metal embossing is a technique that involves the formation of raised or recessed designs on the surface of metal sheets. The process typically begins with the creation of a die, which is a specialized tool designed to imprint a specific design into the metal. Once the die is prepared, it is mounted onto the embossing press, where the metal sheet is placed. The press applies significant pressure, which forces the metal into the contours of the die, resulting in a beautifully embossed design.

This method can be applied to various metals, including aluminum, brass, and stainless steel, offering versatility in terms of the types of products that can be produced. The depth, texture, and clarity of the embossing can be adjusted by modifying the pressure and speed of the press, allowing for a range of design possibilities.

Benefits of Using a Metal Embossing Press

1. Increased Production Efficiency One of the primary advantages of a metal embossing press is its ability to produce high volumes of embossed products in a fraction of the time it would take to create them manually. The automated nature of the press minimizes labor costs and reduces production time, which is vital for businesses looking to meet market demands promptly.

metal embossing press

2. Consistency and Precision The use of a metal embossing press ensures that each piece produced is consistent in quality and precision. This is particularly important in industries where uniformity is key, such as automotive manufacturing or electronics. With precise control over the embossing parameters, manufacturers can achieve intricate designs that remain true across multiple production runs.

3. Cost-Effective Production While the initial investment in a metal embossing press may be significant, the long-term savings it offers are undeniable. Reduced labor intensiveness, minimized waste materials, and decreased production times contribute to overall lower operational costs. As businesses grow and demand increases, the ability to scale production efficiently becomes a crucial advantage.

4. Creative Design Opportunities A metal embossing press opens new avenues for creativity. Designers can experiment with various patterns, textures, and finishes, leading to unique products that can stand out in the marketplace. The flexibility inherent in the embossing process allows for not only aesthetic designs but also functional ones, such as texture purposefully designed to enhance grip or reflect light in specific ways.

Applications of Metal Embossing

The applications for metal embossing are vast and varied. In the jewelry industry, embossed pieces add a luxurious feel and intricate detail to designs, elevating the overall aesthetic. In construction, embossed metal panels are used for both durability and decorative purposes. Automotive manufacturers utilize metal embossing for components that benefit from weight reduction without sacrificing strength. Additionally, embossing is employed in the production of packaging, signage, and decorative art pieces, demonstrating its versatility across different sectors.

Conclusion

In conclusion, the metal embossing press is an invaluable tool that enhances production capabilities while fostering creativity in design. With its ability to produce intricate and consistent designs efficiently, this technology has become essential across various industries. As manufacturing continues to evolve, the metal embossing press will undoubtedly play a critical role in shaping the future of design and production, making it a fundamental aspect of modern craftsmanship. Whether for functional applications or artistic endeavors, the benefits and possibilities offered by metal embossing presses are limitless, marking a significant advancement in the world of manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025