Metal Shaping Equipment for Precision Embossing and Custom Designs in Manufacturing

Understanding Metal Embossing Machines A Craftsmanship Revolution

In the world of manufacturing and design, metal embossing machines have emerged as pivotal tools that encapsulate the intersection of technology and craftsmanship. These machines are designed to create intricate patterns and designs on sheet metal surfaces, transforming ordinary metal sheets into pieces of art and functional elements alike. The significance of metal embossing extends beyond aesthetics; it impacts various industries, including automotive, aerospace, and decorative arts.

What is Metal Embossing?

Metal embossing is the process of creating raised or recessed designs on metal surfaces. This technique can be used for decorative purposes, such as creating intricate patterns for ornamental pieces, or for functional applications, such as enhancing grip on surfaces or creating heat-resistant elements. The process involves the use of stamping tools, dies, and a metal embossing machine, which applies pressure to the metal sheet, causing it to take the shape of the die.

The Working Mechanism of Metal Embossing Machines

Metal embossing machines operate on various principles, including mechanical, hydraulic, and pneumatic systems. Mechanical embossing machines use a cam-driven system to push the embossing die into the metal sheet, while hydraulic machines rely on fluid pressure to deliver force. Pneumatic machines, on the other hand, utilize compressed air, providing an efficient and dynamic way to achieve precise embossing.

Regardless of the type, the fundamental components of these machines include a frame, a table for placing the metal sheet, and the embossing die. The choice of die is crucial, as it determines the final design’s intricacy. Additionally, modern machines often come equipped with computer numerical control (CNC) systems, allowing for enhanced precision and the ability to reproduce complex patterns consistently.

Applications Across Industries

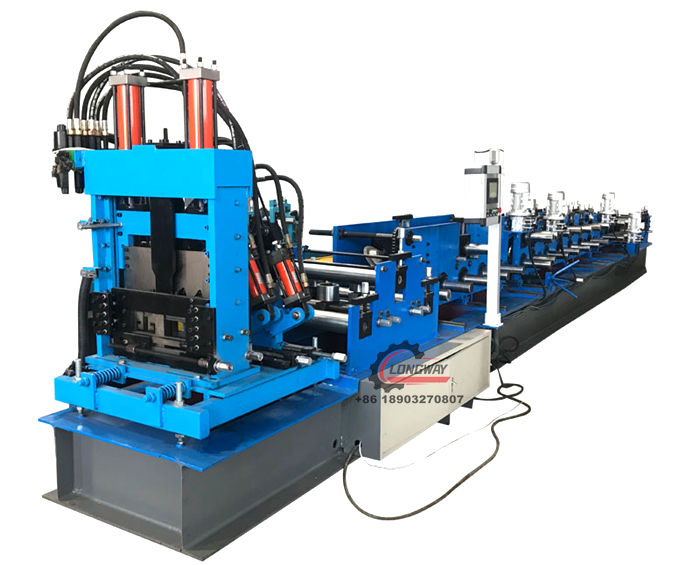

metal embossing machine

The applications of metal embossing machines are vast and varied. In the automotive industry, for instance, embossed metal parts can be found in vehicle interiors, contributing to the aesthetics and comfort. They are also used in the production of nameplates, badges, and logos that enhance brand identity.

In the decorative arts, metal embossing has gained popularity among craftsmen and artists. It allows for the creation of unique home décor items, decorative panels, and personalized gifts. The embossed patterns on metal can bring a touch of elegance, making them sought-after items in galleries and craft fairs.

Additionally, the architectural field utilizes metal embossing for façade designs, decorative ceilings, and signage. The durability of embossed metal surfaces makes them suitable for both indoor and outdoor applications, enhancing aesthetic appeal while ensuring resilience against the elements.

Advantages of Using Metal Embossing Machines

The advantages of metal embossing machines are manifold. Firstly, they allow for the mass production of intricate designs, which would be labor-intensive and costly if done manually. Secondly, they enhance product durability, as embossed patterns provide additional strength to the metal parts. This is particularly beneficial in industries where performance and product longevity are paramount.

Moreover, modern metal embossing machines offer significant flexibility. Designers can easily switch dies to create different patterns, and with CNC technology, modifications can be made swiftly without lengthy downtimes. This adaptability not only improves efficiency but also encourages innovation in design.

Conclusion

The evolution of metal embossing machines marks a significant advancement in the manufacturing and crafting sectors. With their ability to blend function with artistry, these machines are not only tools of production but also instruments of creativity. As industries continue to seek innovative ways to enhance their products, the role of metal embossing machines will undoubtedly expand, paving the way for new possibilities in design and functionality. Whether in creating automotive components or artistic decorations, the impact of these machines is profound, showcasing what is possible at the intersection of technology and craftsmanship.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025