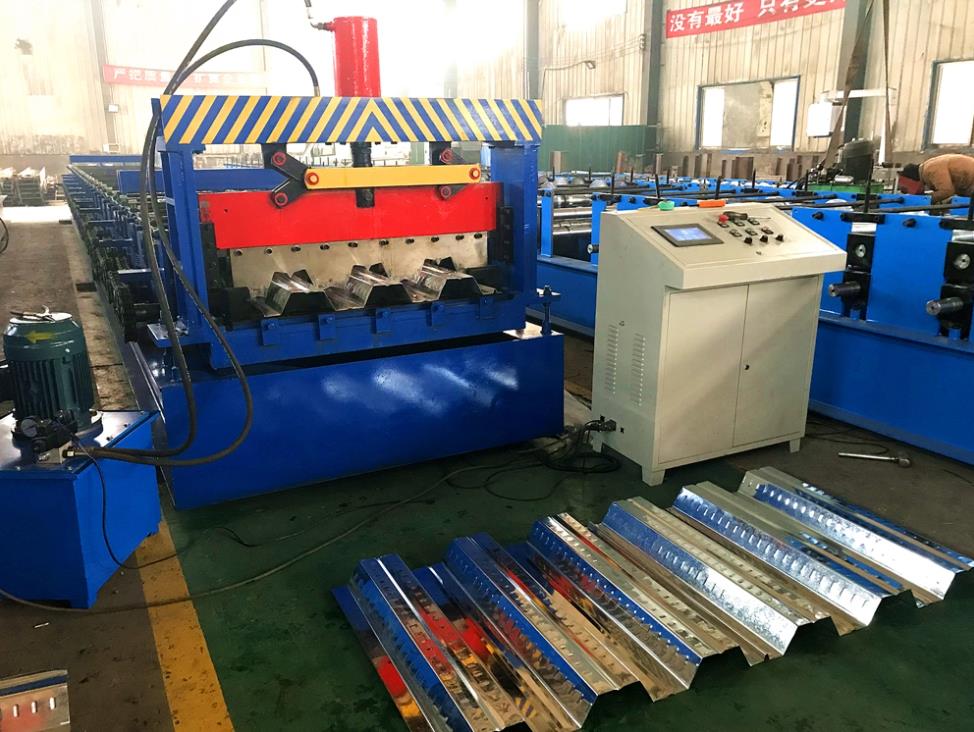

metal deck roll forming machine

Understanding Metal Deck Roll Forming Machines

In the realm of modern construction and manufacturing, efficiency and precision are paramount. One of the most significant innovations that have emerged in this context is the metal deck roll forming machine. These machines are pivotal in producing metal decking, which is a structural element widely used in the construction of floors, roofs, and other applications. This article explores the workings, benefits, and applications of metal deck roll forming machines, shedding light on their importance in contemporary construction.

What Is a Metal Deck Roll Forming Machine?

A metal deck roll forming machine is a highly specialized piece of equipment designed to convert flat metal coils into specific profiles for metal decking. The process involves feeding a coil of metal, often made of steel or aluminum, through a series of rollers that gradually shape the metal into the desired form. This process is known as roll forming, which is highly efficient and allows for continuous production of long metal sections, making it ideal for large-scale applications.

The Roll Forming Process

The roll forming process begins with the setup of the machine. Metal coils are loaded onto a decoiler, which unwinds the coils for processing. As the metal passes through the rollers, it is progressively shaped. The primary role of the rollers is to ensure that the metal is only deformed in the desired areas while maintaining its structural integrity.

Once the metal achieves the right profile, it can be cut to the desired lengths using an integrated cutoff system. Most modern metal deck roll forming machines are fully automated and can operate with minimal human intervention, allowing for high-volume production with consistent quality.

Advantages of Using Metal Deck Roll Forming Machines

1. Efficiency The roll forming process produces metal decking at an impressive speed. This high throughput can significantly lower production costs and meet the demands of large-scale construction projects.

metal deck roll forming machine

2. Customizability These machines can be designed to produce various profiles and thicknesses of metal decking, allowing manufacturers to cater to specific project requirements. Adjusting the design parameters can be done relatively quickly compared to other metal forming processes.

3. Material Optimization Metal deck roll forming machines efficiently utilize raw materials. The continuous nature of the process minimizes waste and allows for the production of long sections, which are often more economical to transport and handle than shorter pieces.

4. Quality The precision of roll forming ensures that the metal decking produced meets rigorous industry standards. The uniformity in thickness and profile helps maintain structural integrity, which is critical in construction applications.

5. Durability Metal decking is inherently strong and resistant to various environmental factors. The roll forming process enhances these qualities, ensuring that the finished products are suitable for use in a variety of settings, from commercial buildings to industrial facilities.

Applications of Metal Decking

Metal decks are widely used in construction projects where strength and lightweight properties are essential. Some common applications include

- Floor Systems Metal deck provides a robust and stable flooring solution for multi-story buildings, warehouses, and parking structures. - Roofing Metal decking serves as a reliable roofing solution, offering excellent load-carrying capacity and resistance to extreme weather conditions. - Bridges In bridge construction, metal decking is utilized for its strength and lightweight nature, which reduces the overall load on the supporting structures. - Partitions and Walls Metal decking can also be used as infill panels in wall systems, contributing to the overall strength and stability of structures.

Conclusion

The metal deck roll forming machine represents a significant advancement in the construction industry, reflecting the ever-increasing demand for efficient, durable, and cost-effective building solutions. Its ability to produce high-quality metal decking serves as a testament to innovation in manufacturing processes. As construction practices continue to evolve, the role of such machines will undoubtedly expand, further enhancing the capabilities of the industry. Whether for creating floors in commercial buildings or roofing solutions for residential projects, metal deck roll forming machines are an integral part of building the future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025