Metal Deck Forming Equipment Manufacturer for Quality Construction Solutions

Exploring the Metal Deck Forming Machine Factory Innovation in Construction Technology

In today's fast-paced construction industry, efficiency and quality are paramount. One of the critical tools that have revolutionized the way we build is the metal deck forming machine. These machines play a vital role in creating metal decking systems that are integral to modern construction projects. Among the many manufacturers, metal deck forming machine factories are at the forefront of innovation, offering advanced solutions that cater to the diverse needs of the construction sector.

What is a Metal Deck Forming Machine?

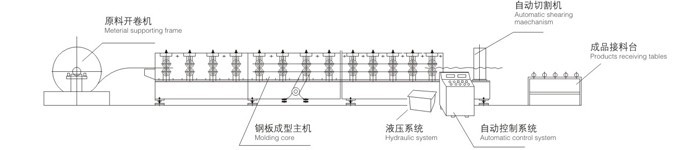

A metal deck forming machine is a specialized piece of equipment designed to produce metal decking panels. These panels are typically used in commercial and industrial buildings, providing a strong, durable platform for flooring and roofing systems. The machines can create a variety of profiles and gauges, allowing for flexibility in design and application. They utilize techniques such as roll forming, which involves continuously shaping metal coils into desired forms through a series of rollers.

The Importance of Metal Decking in Construction

Metal decking is essential for several reasons. First and foremost, it offers superior strength-to-weight ratios, making it an ideal material for constructing floors and roofs. This characteristic not only reduces construction costs but also enhances the overall structural efficiency of buildings. Furthermore, metal decking is fire-resistant and provides excellent resistance to weather elements, making it suitable for a wide range of applications.

The use of metal decks also facilitates faster construction processes. With their lightweight and easy installation characteristics, they can significantly reduce labor costs and shorten project timelines. This efficiency is particularly crucial in projects that require swift completion, such as commercial buildings and warehouses.

metal deck forming machine factory

Innovations in Metal Deck Forming Machine Factories

Metal deck forming machine factories are continually evolving to meet the demands of modern construction. Innovations in technology have led to the development of machines that are more efficient, precise, and user-friendly. For instance, advancements in computerized controls and automation have increased the production speed and accuracy of metal decking. These machines can now be programmed to create complex profiles with minimal human intervention, reducing the risk of errors and material waste.

Moreover, many manufacturers are focusing on sustainability. Newer machines are designed to minimize energy consumption and optimize raw material usage, aligning with the growing trend of environmentally friendly construction practices. Additionally, some factories utilize recycled materials in their production processes, contributing to a more sustainable construction industry.

The Role of Quality Control

Quality control is a critical aspect of operations in metal deck forming machine factories. The processes involved in metal deck production must adhere to strict industry standards and regulations to ensure safety and performance. Factories implement rigorous testing measures to evaluate the durability and load-bearing capabilities of the metal decks they produce. This commitment to quality ensures that the final products meet or exceed the expectations of clients, thus fostering trust and long-term relationships in the market.

Conclusion

Metal deck forming machine factories are instrumental in shaping the future of the construction industry. By providing innovative, efficient, and high-quality solutions, they enable builders to meet the ever-increasing demands for speed and safety in construction. As technology continues to advance, these factories will likely play an even more significant role, pushing the boundaries of what is possible in construction and contributing to the development of sustainable, resilient infrastructures. The journey of innovation in metal decking is just beginning, and the potential for the future is limitless.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025