metal roofing moulding machine

The Importance of Metal Roofing Moulding Machines

In the construction industry, the choice of materials plays a crucial role in the performance, durability, and aesthetic appeal of buildings. Among these materials, metal roofing has gained tremendous popularity due to its longevity, energy efficiency, and modern look. To streamline the production of metal roofing components, metal roofing moulding machines have become indispensable tools for manufacturers worldwide.

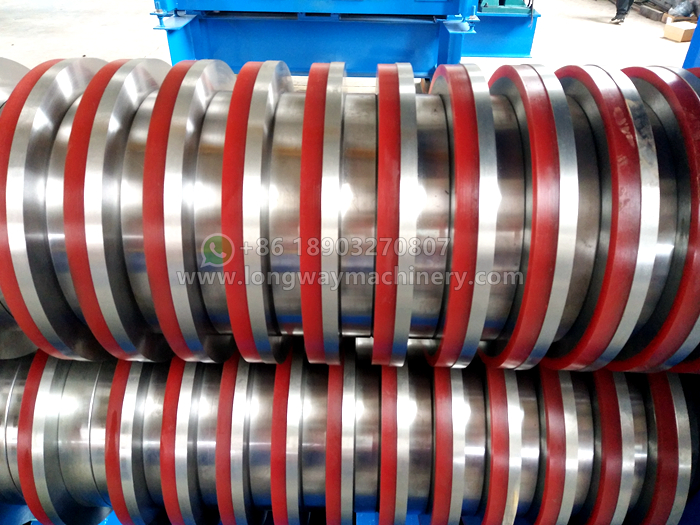

Metal roofing moulding machines are specialized equipment designed to shape and form metal sheets into various profiles suitable for roofing applications. These machines facilitate the creation of different styles, including standing seam, corrugated, and tile-like designs. The flexibility of these machines allows manufacturers to meet diverse customer demands for aesthetics and functionality.

One significant advantage of using metal roofing moulding machines is the improved efficiency in production. Traditional methods of roofing material production can be time-consuming and labor-intensive, often resulting in inconsistencies in quality. With the automated processes offered by moulding machines, manufacturers can achieve higher precision and uniformity in their products. This not only reduces waste but also lowers production costs, enabling companies to offer competitive prices while maintaining profitability.

metal roofing moulding machine

Additionally, metal roofing moulding machines contribute to the sustainability of the construction industry. Metal roofing itself is a recyclable material, and the machines used to manufacture it can minimize scrap and reduce energy consumption during production. By investing in energy-efficient moulding technology, manufacturers can not only reduce their carbon footprint but also appeal to environmentally conscious consumers looking for sustainable building solutions.

Moreover, the versatility of metal roofing moulding machines allows for customization, which is becoming increasingly essential in the construction sector. Clients often seek unique designs and color options that fit their specific architectural visions. Moulding machines can easily adapt to create custom profiles, thereby enhancing the creative possibilities for architects and builders. This level of customization fosters innovation in building designs, ultimately resulting in more visually appealing and functional structures.

Another key factor in the popularity of metal roofing moulding machines is the growing awareness of the benefits of metal roofs. Metal roofing is known for its longevity, often lasting over 50 years with proper maintenance. It can withstand harsh weather conditions, including hail, heavy snow, and high winds, making it an ideal choice for many locations. The integration of moulding machines in production ensures that this resilient material is readily available to the market in various forms and styles.

In conclusion, metal roofing moulding machines play a vital role in the construction industry by enhancing the efficiency, precision, and sustainability of metal roofing production. As the demand for metal roofs continues to grow, these machines will undoubtedly remain a critical component of manufacturing processes. By investing in advanced moulding technology, manufacturers can not only improve their operational capabilities but also meet the evolving needs of their customers in a competitive market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025