Jun . 15, 2024 21:52

Back to list

Metal Roof Ridge Cap Roll Forming Machine Factories

Metal Roof Ridge Cap Roll Forming Machine Factories A Comprehensive Guide

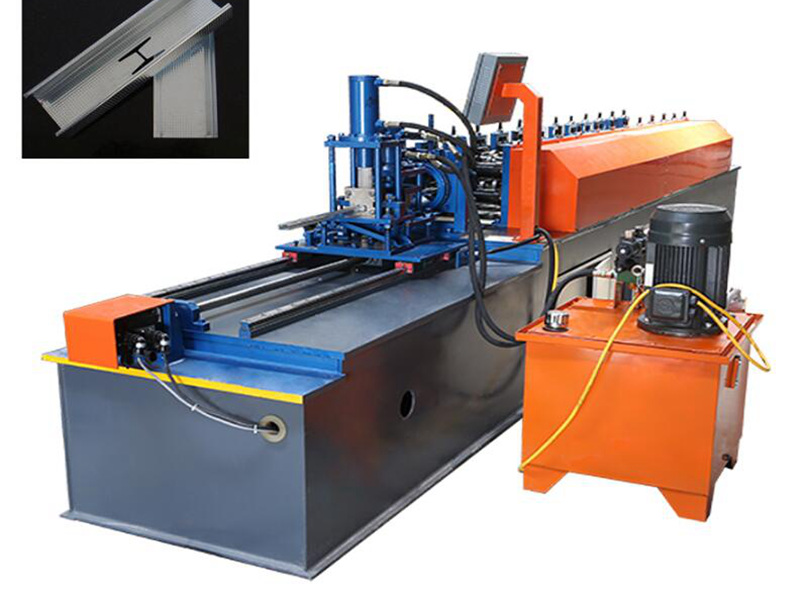

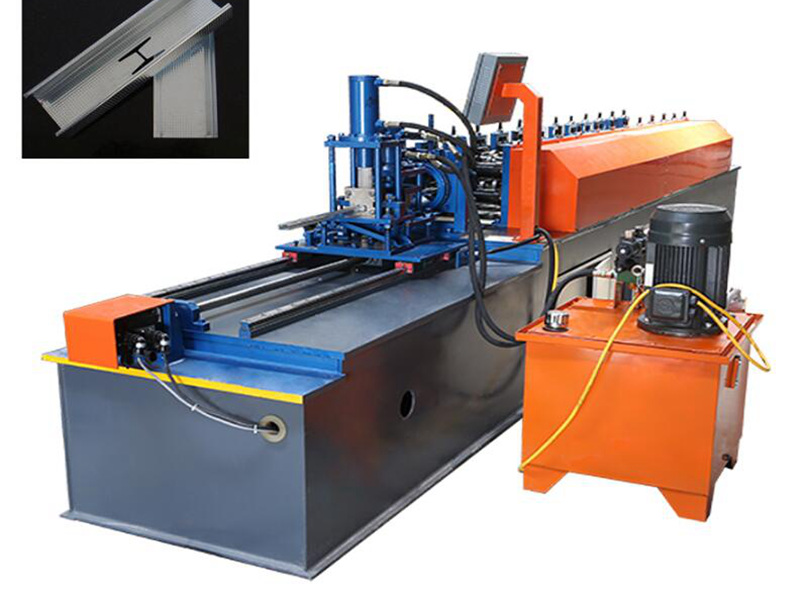

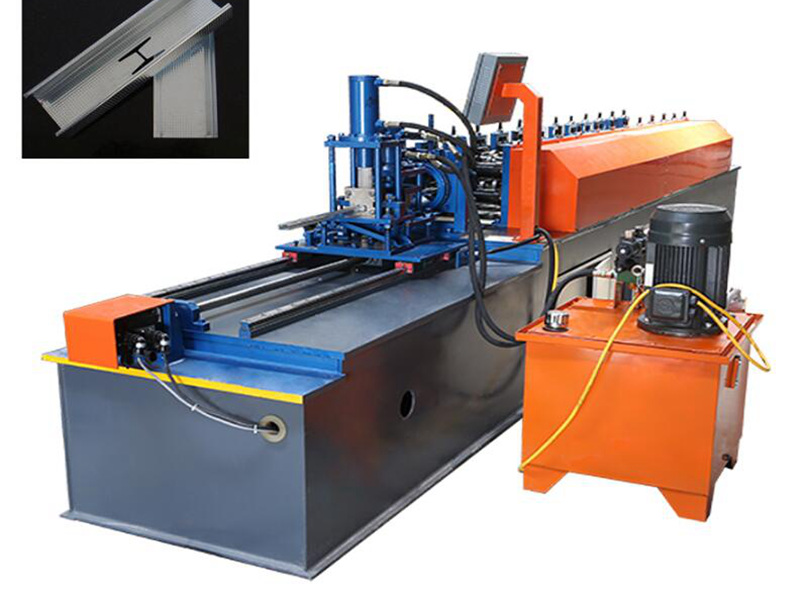

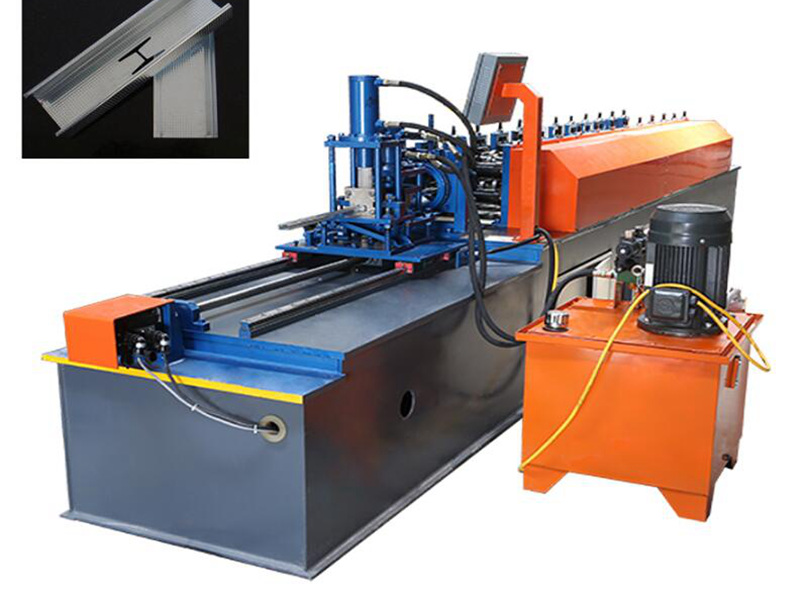

Metal roof ridge cap roll forming machines are essential for the production of high-quality metal roof ridge caps. These machines are specifically designed to form and shape metal sheets into the desired ridge cap profile, which is then used to cover the gap between the roof and the wall of a building. This not only enhances the aesthetic appeal of the building but also provides protection against water leakage and other weather-related damages.

In this article, we will delve into the world of metal roof ridge cap roll forming machine factories, exploring their significance, types, key components, and manufacturing processes. We will also discuss the factors to consider when selecting a suitable factory for your specific needs.

Significance of Metal Roof Ridge Cap Roll Forming Machine Factories

Metal roof ridge cap roll forming machines play a crucial role in the construction industry, as they help to increase efficiency, reduce costs, and improve the quality of metal roof ridge caps. These machines can produce large quantities of ridge caps in a short period, thereby reducing labor costs and minimizing downtime. Additionally, the use of these machines results in consistent quality, as the process is highly automated and controlled.

Types of Metal Roof Ridge Cap Roll Forming Machines

There are several types of metal roof ridge cap roll forming machines available in the market, each with its own unique features and capabilities. Some of the most common types include

1. Manual roll forming machines These machines are operated manually, with operators feeding the metal sheet into the machine and adjusting the settings as needed. While these machines are relatively inexpensive, they are generally slower and less efficient than automatic machines.

2. Semi-automatic roll forming machines These machines are partially automated, with operators feeding the metal sheet into the machine and automatically adjusting the settings as needed. These machines offer a good balance between cost and efficiency, making them a popular choice for many businesses.

3. Fully automatic roll forming machines These machines are completely automated, with operators loading the metal sheet and setting the parameters, while the machine takes care of the rest. These machines are the most efficient and accurate, but they also come with a higher price tag.

Key Components of Metal Roof Ridge Cap Roll Forming Machines

The key components of a metal roof ridge cap roll forming machine include

1. Rollers These are the main working components of the machine, responsible for shaping the metal sheet into the desired profile. The rollers are typically made of hardened steel and are arranged in a series of dies that gradually shape the metal as it passes through the machine.

2. Drive system This component provides the power to rotate the rollers and move the metal sheet through the machine. The drive system can be powered by electric motors, hydraulic motors, or pneumatic motors, depending on the specific requirements of the machine.

3. Control system This component is responsible for controlling the operation of the machine, including setting the parameters, monitoring the process, and adjusting the settings as needed. The control system can be manual, semi-automatic, or fully automatic, depending on the type of machine.

4.。、、,、。

5. 。、,。

Manufacturing Process of Metal Roof Ridge Cap Roll Forming Machines

The manufacturing process of metal roof ridge cap roll forming machines involves several steps, including

1 。、,。

Manufacturing Process of Metal Roof Ridge Cap Roll Forming Machines

The manufacturing process of metal roof ridge cap roll forming machines involves several steps, including

1 。、,。

Manufacturing Process of Metal Roof Ridge Cap Roll Forming Machines

The manufacturing process of metal roof ridge cap roll forming machines involves several steps, including

1 。、,。

Manufacturing Process of Metal Roof Ridge Cap Roll Forming Machines

The manufacturing process of metal roof ridge cap roll forming machines involves several steps, including

1

。、,。

Manufacturing Process of Metal Roof Ridge Cap Roll Forming Machines

The manufacturing process of metal roof ridge cap roll forming machines involves several steps, including

1 。、,。

Manufacturing Process of Metal Roof Ridge Cap Roll Forming Machines

The manufacturing process of metal roof ridge cap roll forming machines involves several steps, including

1 metal roof ridge cap roll forming machine factories. Design and engineering This step involves creating detailed drawings and specifications for the machine based on the customer's requirements. The design team works closely with the customer to ensure that the machine meets their specific needs.

2. Manufacturing Once the design is finalized, the machine is manufactured in a clean and well-equipped workshop. The various components of the machine are carefully fabricated and assembled to ensure that they are of high quality and precision.

3. Testing and commissioning After the machine is assembled, it undergoes rigorous testing and commissioning to ensure that it operates correctly and efficiently. The testing process includes running the machine at different speeds and loads to check its performance and reliability.

4. Packaging and delivery Once the machine has passed all the tests, it is carefully packaged and delivered to the customer. The packaging process ensures that the machine is protected during transportation and handling.

Factors to Consider When Selecting a Metal Roof Ridge Cap Roll Forming Machine Factory

When selecting a metal roof ridge cap roll forming machine factory, there are several factors to consider, including

1. Quality Look for a factory that has a reputation for producing high-quality machines. This can be assessed by reviewing the factory's track record, customer feedback, and industry awards.

2. Experience Choose a factory that has extensive experience in manufacturing metal roof ridge cap roll forming machines. This can be determined by looking at the factory's portfolio, the number of machines they have produced, and the length of time they have been in business.

3. Technical support Ensure that the factory offers reliable technical support throughout the entire lifecycle of the machine. This includes installation, training, maintenance, and repairs.

4. Cost Compare the prices offered by different factories to find the best value for money. However, do not compromise on quality just to save a few dollars.

5. Location Consider the location of the factory when selecting a supplier. A nearby factory may be more convenient and cost-effective in terms of transportation and communication.

In conclusion, metal roof ridge cap roll forming machine factories play a vital role in the construction industry by providing high-quality machines that increase efficiency, reduce costs, and improve the overall appearance of buildings. By considering the factors outlined in this article, you can select a suitable factory that meets your specific needs and requirements.

metal roof ridge cap roll forming machine factories. Design and engineering This step involves creating detailed drawings and specifications for the machine based on the customer's requirements. The design team works closely with the customer to ensure that the machine meets their specific needs.

2. Manufacturing Once the design is finalized, the machine is manufactured in a clean and well-equipped workshop. The various components of the machine are carefully fabricated and assembled to ensure that they are of high quality and precision.

3. Testing and commissioning After the machine is assembled, it undergoes rigorous testing and commissioning to ensure that it operates correctly and efficiently. The testing process includes running the machine at different speeds and loads to check its performance and reliability.

4. Packaging and delivery Once the machine has passed all the tests, it is carefully packaged and delivered to the customer. The packaging process ensures that the machine is protected during transportation and handling.

Factors to Consider When Selecting a Metal Roof Ridge Cap Roll Forming Machine Factory

When selecting a metal roof ridge cap roll forming machine factory, there are several factors to consider, including

1. Quality Look for a factory that has a reputation for producing high-quality machines. This can be assessed by reviewing the factory's track record, customer feedback, and industry awards.

2. Experience Choose a factory that has extensive experience in manufacturing metal roof ridge cap roll forming machines. This can be determined by looking at the factory's portfolio, the number of machines they have produced, and the length of time they have been in business.

3. Technical support Ensure that the factory offers reliable technical support throughout the entire lifecycle of the machine. This includes installation, training, maintenance, and repairs.

4. Cost Compare the prices offered by different factories to find the best value for money. However, do not compromise on quality just to save a few dollars.

5. Location Consider the location of the factory when selecting a supplier. A nearby factory may be more convenient and cost-effective in terms of transportation and communication.

In conclusion, metal roof ridge cap roll forming machine factories play a vital role in the construction industry by providing high-quality machines that increase efficiency, reduce costs, and improve the overall appearance of buildings. By considering the factors outlined in this article, you can select a suitable factory that meets your specific needs and requirements.

。、,。

Manufacturing Process of Metal Roof Ridge Cap Roll Forming Machines

The manufacturing process of metal roof ridge cap roll forming machines involves several steps, including

1 。、,。

Manufacturing Process of Metal Roof Ridge Cap Roll Forming Machines

The manufacturing process of metal roof ridge cap roll forming machines involves several steps, including

1

。、,。

Manufacturing Process of Metal Roof Ridge Cap Roll Forming Machines

The manufacturing process of metal roof ridge cap roll forming machines involves several steps, including

1 。、,。

Manufacturing Process of Metal Roof Ridge Cap Roll Forming Machines

The manufacturing process of metal roof ridge cap roll forming machines involves several steps, including

1 metal roof ridge cap roll forming machine factories. Design and engineering This step involves creating detailed drawings and specifications for the machine based on the customer's requirements. The design team works closely with the customer to ensure that the machine meets their specific needs.

2. Manufacturing Once the design is finalized, the machine is manufactured in a clean and well-equipped workshop. The various components of the machine are carefully fabricated and assembled to ensure that they are of high quality and precision.

3. Testing and commissioning After the machine is assembled, it undergoes rigorous testing and commissioning to ensure that it operates correctly and efficiently. The testing process includes running the machine at different speeds and loads to check its performance and reliability.

4. Packaging and delivery Once the machine has passed all the tests, it is carefully packaged and delivered to the customer. The packaging process ensures that the machine is protected during transportation and handling.

Factors to Consider When Selecting a Metal Roof Ridge Cap Roll Forming Machine Factory

When selecting a metal roof ridge cap roll forming machine factory, there are several factors to consider, including

1. Quality Look for a factory that has a reputation for producing high-quality machines. This can be assessed by reviewing the factory's track record, customer feedback, and industry awards.

2. Experience Choose a factory that has extensive experience in manufacturing metal roof ridge cap roll forming machines. This can be determined by looking at the factory's portfolio, the number of machines they have produced, and the length of time they have been in business.

3. Technical support Ensure that the factory offers reliable technical support throughout the entire lifecycle of the machine. This includes installation, training, maintenance, and repairs.

4. Cost Compare the prices offered by different factories to find the best value for money. However, do not compromise on quality just to save a few dollars.

5. Location Consider the location of the factory when selecting a supplier. A nearby factory may be more convenient and cost-effective in terms of transportation and communication.

In conclusion, metal roof ridge cap roll forming machine factories play a vital role in the construction industry by providing high-quality machines that increase efficiency, reduce costs, and improve the overall appearance of buildings. By considering the factors outlined in this article, you can select a suitable factory that meets your specific needs and requirements.

metal roof ridge cap roll forming machine factories. Design and engineering This step involves creating detailed drawings and specifications for the machine based on the customer's requirements. The design team works closely with the customer to ensure that the machine meets their specific needs.

2. Manufacturing Once the design is finalized, the machine is manufactured in a clean and well-equipped workshop. The various components of the machine are carefully fabricated and assembled to ensure that they are of high quality and precision.

3. Testing and commissioning After the machine is assembled, it undergoes rigorous testing and commissioning to ensure that it operates correctly and efficiently. The testing process includes running the machine at different speeds and loads to check its performance and reliability.

4. Packaging and delivery Once the machine has passed all the tests, it is carefully packaged and delivered to the customer. The packaging process ensures that the machine is protected during transportation and handling.

Factors to Consider When Selecting a Metal Roof Ridge Cap Roll Forming Machine Factory

When selecting a metal roof ridge cap roll forming machine factory, there are several factors to consider, including

1. Quality Look for a factory that has a reputation for producing high-quality machines. This can be assessed by reviewing the factory's track record, customer feedback, and industry awards.

2. Experience Choose a factory that has extensive experience in manufacturing metal roof ridge cap roll forming machines. This can be determined by looking at the factory's portfolio, the number of machines they have produced, and the length of time they have been in business.

3. Technical support Ensure that the factory offers reliable technical support throughout the entire lifecycle of the machine. This includes installation, training, maintenance, and repairs.

4. Cost Compare the prices offered by different factories to find the best value for money. However, do not compromise on quality just to save a few dollars.

5. Location Consider the location of the factory when selecting a supplier. A nearby factory may be more convenient and cost-effective in terms of transportation and communication.

In conclusion, metal roof ridge cap roll forming machine factories play a vital role in the construction industry by providing high-quality machines that increase efficiency, reduce costs, and improve the overall appearance of buildings. By considering the factors outlined in this article, you can select a suitable factory that meets your specific needs and requirements. Latest news

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

Related Products