Maximize Your Production with Advanced Downspout Machines

In the ever-evolving construction industry, efficiency and quality are key to success. For businesses involved in the manufacturing of downspouts, investing in a downspout machine can significantly enhance productivity and product quality. This advertorial explores the benefits of utilizing a downspout roll forming machine and highlights the advantages of choosing the right manufacturer to meet your production needs.

Why Choose a Downspout Machine Manufacturer?

Partnering with a reliable downspout machine manufacturer is crucial for businesses looking to boost their production capabilities. These manufacturers specialize in designing machines tailored specifically for downspout production, ensuring precision and efficiency. When you work with a reputable manufacturer, you gain access to advanced technology and equipment that can streamline your operations. A specialized manufacturer understands the unique requirements of downspout production, offering solutions that enhance quality while reducing waste and labor costs.

The Advantages of a Downspout Roll Forming Machine

Investing in a downspout roll forming machine provides numerous advantages for manufacturers. These machines allow for the efficient production of downspouts in various sizes and profiles, accommodating diverse customer demands. The automated nature of roll forming technology ensures consistent quality, reducing the likelihood of defects and rework. Additionally, these machines offer high-speed production capabilities, enabling manufacturers to meet tight deadlines while maintaining quality standards. With a downspout roll forming machine, your business can enhance productivity and expand its product offerings.

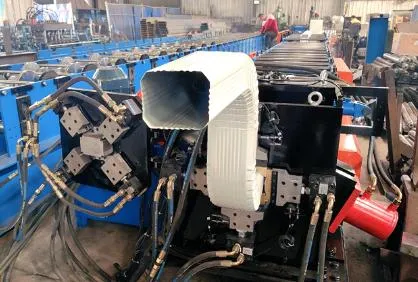

Understanding the Functionality of a Downspout Pipe Roll Forming Machine

A downspout pipe roll forming machine operates by feeding metal coils through a series of rollers that shape the material into the desired profile. This process not only ensures uniformity in product dimensions but also allows for the efficient creation of downspouts with minimal waste. By utilizing this technology, manufacturers can produce downspouts quickly and accurately, meeting market demands without compromising quality. Understanding the functionality of these machines is essential for making an informed purchasing decision and maximizing production efficiency.

Importance of Quality in Downspout Manufacturing

Quality is paramount in downspout manufacturing, as these components play a critical role in water management systems. A high-quality downspout roll forming machine ensures that every product meets industry standards and customer expectations. Investing in reliable machinery minimizes defects, resulting in fewer returns and enhanced customer satisfaction. Furthermore, superior quality products can lead to stronger brand reputation and increased sales. By prioritizing quality in your production process, you can establish your business as a leader in the market.

Finding the Right Downspout Machine Manufacturer

Choosing the right downspout machine manufacturer is essential for ensuring a successful investment. When evaluating potential manufacturers, consider their reputation, customer service, and the quality of their machinery. Look for manufacturers that offer comprehensive support, including training, maintenance, and spare parts availability. Customer testimonials and reviews can also provide insight into the reliability and performance of their machines. By selecting a trustworthy manufacturer, you can ensure a smooth production process and long-term satisfaction with your investment.

Investing in a downspout machine can significantly enhance your production capabilities in the construction industry. By partnering with a specialized downspout machine manufacturer, utilizing advanced downspout roll forming machines, and understanding the importance of quality, your business can thrive in a competitive market. Embrace the benefits of modern manufacturing technology and elevate your downspout production to new heights!

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025