maquina industrial metalcon factory

The Industrial Metalworking Machine Factory A Cornerstone of Modern Manufacturing

In today's rapidly advancing industrial landscape, the significance of specialized factories such as the metalworking machine factory cannot be overstated. These facilities serve as the backbone of manufacturing, providing essential machinery that enables various industries to thrive. The maquina industrial metalcon factory epitomizes the capabilities and innovations found within the realm of industrial machine production.

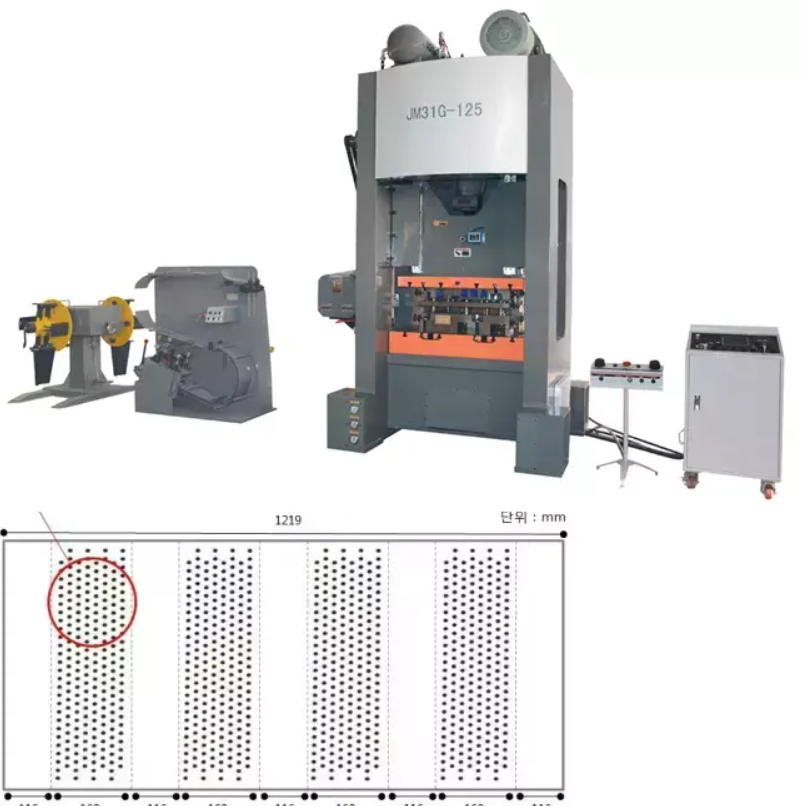

At its core, a metalworking machine factory is designed to produce a variety of machinery that processes metal into workable forms. This includes a wide range of equipment, such as lathes, milling machines, grinders, and CNC (computer numerical control) machines. Each piece of machinery plays a crucial role in transforming raw materials into finished products, catering to diverse sectors including automotive, aerospace, construction, and energy.

The maquina industrial metalcon factory stands out due to its commitment to precision engineering and quality control. The production process starts with the careful selection of raw materials, typically high-grade metals that ensure durability and functionality. Once materials are chosen, they undergo a series of processes that include cutting, shaping, and assembling. Advanced technology, such as laser cutting and automated robotics, often plays a critical role in enhancing accuracy and efficiency during these stages.

Quality assurance is paramount in a metalworking machine factory. Each machine must meet stringent industry standards and regulations before it is deemed fit for the market. This involves rigorous testing and inspection protocols that assess each machine's performance, reliability, and safety. By adhering to these high standards, the maquina industrial metalcon factory not only secures its reputation in the industry but also builds long-lasting relationships with its clients who rely on the performance of their machinery.

maquina industrial metalcon factory

Moreover, the innovation within metalworking machine factories is constantly evolving. Manufacturers are increasingly integrating smart technologies into their machines, resulting in the rise of Industry 4.0. This new paradigm emphasizes automation, data exchange, and IoT (Internet of Things) connectivity, allowing for real-time monitoring and predictive maintenance. Such advancements enable factories to optimize production processes, reduce downtime, and enhance overall efficiency.

Sustainability is another crucial aspect of the modern metalworking machine factory. As society becomes more conscious of environmental impacts, factories are implementing eco-friendly practices. This can include the use of renewable energy sources, recycling waste materials, and developing machines that consume less power. The maquina industrial metalcon factory actively seeks to minimize its carbon footprint while providing cutting-edge machinery that meets the demands of the eco-conscious market.

The workforce in a metalworking machine factory is equally vital to its success. Skilled labor is essential for operating complex machinery, conducting maintenance, and implementing quality control measures. Therefore, investing in workforce training and development is a priority. Such efforts ensure that employees are well-equipped with the necessary skills to handle emerging technologies and adapt to the evolving industrial landscape.

In conclusion, the maquina industrial metalcon factory represents the essence of modern manufacturing through its production of high-quality metalworking machinery. With a focus on precision engineering, quality assurance, technological innovation, environmental sustainability, and workforce development, it stands as a vital player in the global industrial sector. As industries continue to grow and evolve, factories like these will remain instrumental in driving forward the capabilities of manufacturing, meeting the challenges of tomorrow, and shaping the future of production.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025