Jul . 05, 2024 01:50

Back to list

Manufacturing a Roofing Sheet Roll Forming Machine for Efficient Roof Installation Processes.

Roofing Sheet Roll Forming Machine A Game-Changer in the Construction Industry

Roofing is an essential part of any building structure, providing protection from the elements and enhancing the overall aesthetics of the property. With the advancement of technology, roofing materials have evolved over the years, with metal roofing becoming a popular choice for its durability, longevity, and aesthetic appeal.

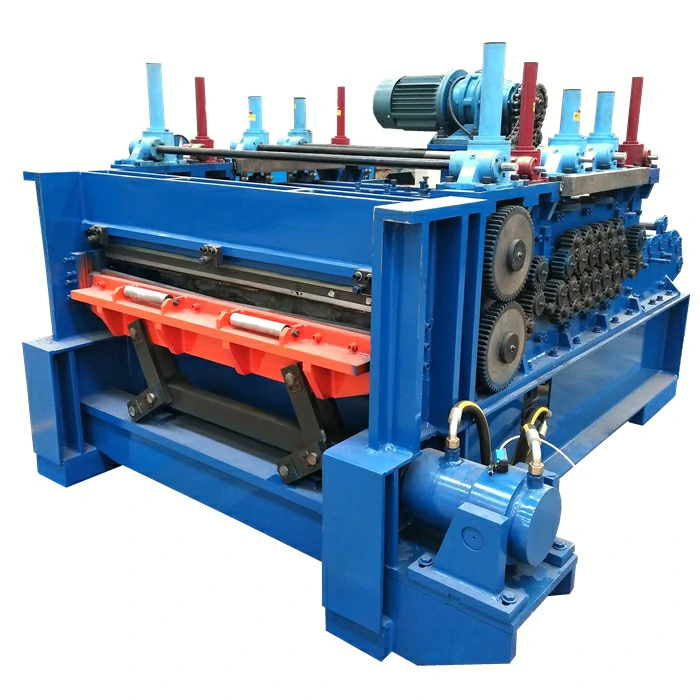

One of the key components in producing metal roofing sheets is the roofing sheet roll forming machine. This machine plays a crucial role in the manufacturing process, allowing for the precise and efficient production of metal roofing sheets. By feeding metal coils through a series of rollers and molds, the machine shapes the metal into the desired profile, creating uniform and high-quality roofing sheets.

The roofing sheet roll forming machine has revolutionized the construction industry by streamlining the production process and improving the overall quality of metal roofing materials. Here are some of the key advantages of using this machine

1. Efficiency The roofing sheet roll forming machine can produce large quantities of metal roofing sheets in a short amount of time, significantly improving the efficiency of the manufacturing process. This allows builders and contractors to meet tight deadlines and complete projects on time.

2. Precision The machine is capable of producing roofing sheets with a high level of precision and accuracy, ensuring that each sheet meets the required dimensions and specifications. This results in uniform and consistent roofing materials that are of superior quality.

3

3 3

3

3

3 roofing sheet roll forming machine. Versatility The roofing sheet roll forming machine can be customized to produce a wide range of roofing profiles, including standing seam, corrugated, and trapezoidal sheets. This versatility allows builders and contractors to choose the right profile for their specific project requirements.

4. Cost-Effectiveness By automating the production process, the machine helps reduce labor costs and minimize material wastage. This results in cost savings for manufacturers, contractors, and ultimately, the end-users.

5. Durability Metal roofing sheets produced using a roll forming machine are known for their durability and longevity. They are resistant to corrosion, rust, and extreme weather conditions, making them an ideal choice for long-lasting roofing solutions.

In conclusion, the roofing sheet roll forming machine has become a game-changer in the construction industry by improving efficiency, precision, versatility, cost-effectiveness, and durability in the production of metal roofing sheets. With its advanced technology and innovative design, this machine has set new benchmarks in the roofing industry and is a valuable asset for builders, contractors, and manufacturers.

roofing sheet roll forming machine. Versatility The roofing sheet roll forming machine can be customized to produce a wide range of roofing profiles, including standing seam, corrugated, and trapezoidal sheets. This versatility allows builders and contractors to choose the right profile for their specific project requirements.

4. Cost-Effectiveness By automating the production process, the machine helps reduce labor costs and minimize material wastage. This results in cost savings for manufacturers, contractors, and ultimately, the end-users.

5. Durability Metal roofing sheets produced using a roll forming machine are known for their durability and longevity. They are resistant to corrosion, rust, and extreme weather conditions, making them an ideal choice for long-lasting roofing solutions.

In conclusion, the roofing sheet roll forming machine has become a game-changer in the construction industry by improving efficiency, precision, versatility, cost-effectiveness, and durability in the production of metal roofing sheets. With its advanced technology and innovative design, this machine has set new benchmarks in the roofing industry and is a valuable asset for builders, contractors, and manufacturers.

3

3

3

3 roofing sheet roll forming machine. Versatility The roofing sheet roll forming machine can be customized to produce a wide range of roofing profiles, including standing seam, corrugated, and trapezoidal sheets. This versatility allows builders and contractors to choose the right profile for their specific project requirements.

4. Cost-Effectiveness By automating the production process, the machine helps reduce labor costs and minimize material wastage. This results in cost savings for manufacturers, contractors, and ultimately, the end-users.

5. Durability Metal roofing sheets produced using a roll forming machine are known for their durability and longevity. They are resistant to corrosion, rust, and extreme weather conditions, making them an ideal choice for long-lasting roofing solutions.

In conclusion, the roofing sheet roll forming machine has become a game-changer in the construction industry by improving efficiency, precision, versatility, cost-effectiveness, and durability in the production of metal roofing sheets. With its advanced technology and innovative design, this machine has set new benchmarks in the roofing industry and is a valuable asset for builders, contractors, and manufacturers.

roofing sheet roll forming machine. Versatility The roofing sheet roll forming machine can be customized to produce a wide range of roofing profiles, including standing seam, corrugated, and trapezoidal sheets. This versatility allows builders and contractors to choose the right profile for their specific project requirements.

4. Cost-Effectiveness By automating the production process, the machine helps reduce labor costs and minimize material wastage. This results in cost savings for manufacturers, contractors, and ultimately, the end-users.

5. Durability Metal roofing sheets produced using a roll forming machine are known for their durability and longevity. They are resistant to corrosion, rust, and extreme weather conditions, making them an ideal choice for long-lasting roofing solutions.

In conclusion, the roofing sheet roll forming machine has become a game-changer in the construction industry by improving efficiency, precision, versatility, cost-effectiveness, and durability in the production of metal roofing sheets. With its advanced technology and innovative design, this machine has set new benchmarks in the roofing industry and is a valuable asset for builders, contractors, and manufacturers. Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products