Jul . 08, 2024 16:30

Back to list

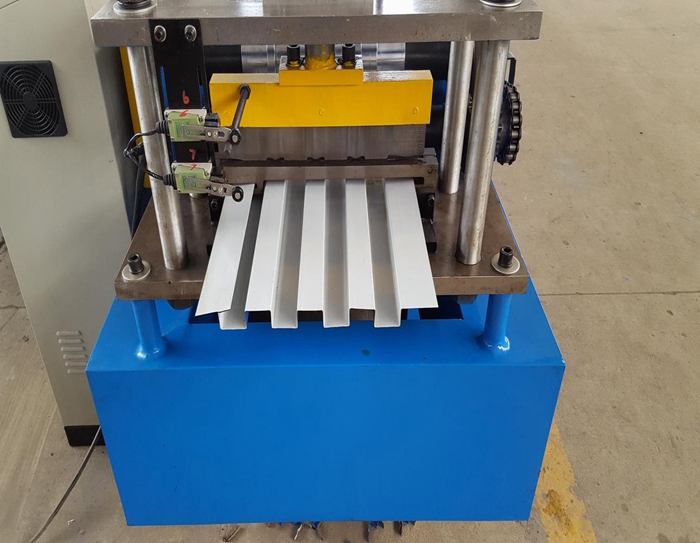

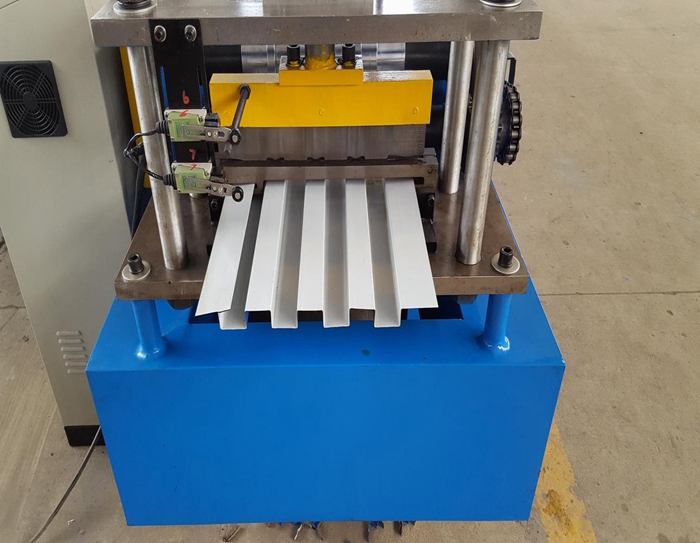

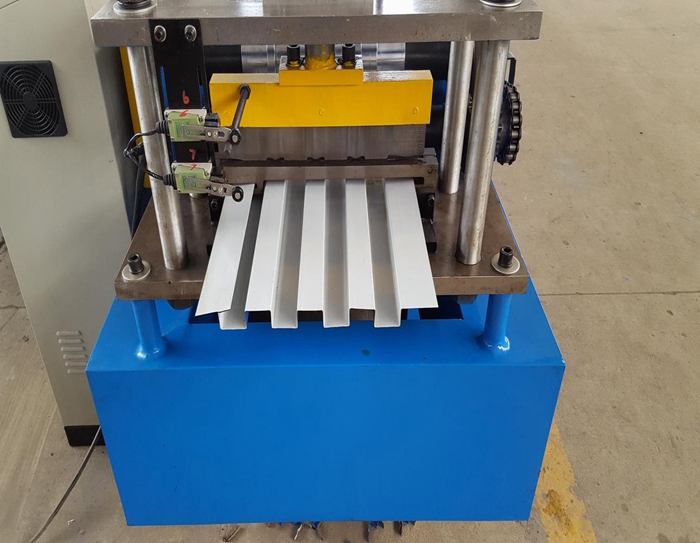

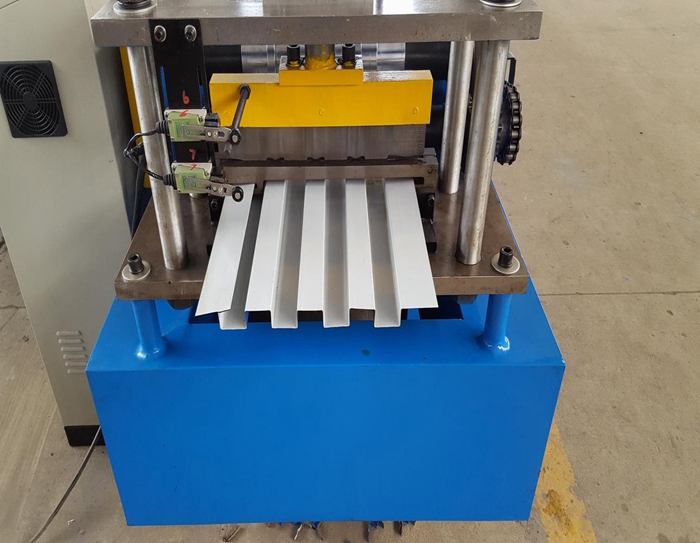

Manufacturers of u-channel roll forming machine with high quality and reliable performance

U-channel roll forming machines are essential pieces of equipment in the manufacturing industry, especially in the production of U-shaped channel components. They are specifically designed to efficiently and accurately bend and shape metal sheets into U-channel profiles, which are commonly used in various construction, automotive, and electrical applications.

There are several manufacturers of U-channel roll forming machines in the market, each offering different features and capabilities. These machines typically consist of a series of rollers and tools that gradually bend and form the metal sheet into the desired U-channel shape. The process is automated and can produce high-quality, consistent results with minimal manual intervention.

One of the key advantages of using a U-channel roll forming machine is its ability to mass-produce U-channel components with precise dimensions and tight tolerances. This is crucial for industries where uniformity and accuracy are essential for the final product's performance and reliability.

Manufacturers of U-channel roll forming machines often offer a range of customization options to accommodate different production requirements. This includes adjustable roller settings, hydraulic systems for precise bending control, and additional features such as hole punching and cutting functionalities This includes adjustable roller settings, hydraulic systems for precise bending control, and additional features such as hole punching and cutting functionalities This includes adjustable roller settings, hydraulic systems for precise bending control, and additional features such as hole punching and cutting functionalities This includes adjustable roller settings, hydraulic systems for precise bending control, and additional features such as hole punching and cutting functionalities

This includes adjustable roller settings, hydraulic systems for precise bending control, and additional features such as hole punching and cutting functionalities This includes adjustable roller settings, hydraulic systems for precise bending control, and additional features such as hole punching and cutting functionalities u channel roll forming machine manufacturers.

In addition to their efficiency and accuracy, U-channel roll forming machines are also known for their durability and reliability. They are built to withstand the rigors of continuous operation and are designed to minimize maintenance and downtime, ensuring consistent production output over time.

When choosing a U-channel roll forming machine manufacturer, it is important to consider factors such as the machine's production capacity, speed, flexibility, and overall quality. It is also advisable to look for manufacturers with a proven track record of delivering high-quality machines and excellent customer support.

In conclusion, U-channel roll forming machines are indispensable tools for the manufacturing industry, offering a fast, efficient, and cost-effective way to produce U-channel components. By selecting a reputable manufacturer and investing in a high-quality machine, businesses can streamline their production processes and achieve superior results in their U-channel manufacturing operations.

u channel roll forming machine manufacturers.

In addition to their efficiency and accuracy, U-channel roll forming machines are also known for their durability and reliability. They are built to withstand the rigors of continuous operation and are designed to minimize maintenance and downtime, ensuring consistent production output over time.

When choosing a U-channel roll forming machine manufacturer, it is important to consider factors such as the machine's production capacity, speed, flexibility, and overall quality. It is also advisable to look for manufacturers with a proven track record of delivering high-quality machines and excellent customer support.

In conclusion, U-channel roll forming machines are indispensable tools for the manufacturing industry, offering a fast, efficient, and cost-effective way to produce U-channel components. By selecting a reputable manufacturer and investing in a high-quality machine, businesses can streamline their production processes and achieve superior results in their U-channel manufacturing operations.

This includes adjustable roller settings, hydraulic systems for precise bending control, and additional features such as hole punching and cutting functionalities This includes adjustable roller settings, hydraulic systems for precise bending control, and additional features such as hole punching and cutting functionalities

This includes adjustable roller settings, hydraulic systems for precise bending control, and additional features such as hole punching and cutting functionalities This includes adjustable roller settings, hydraulic systems for precise bending control, and additional features such as hole punching and cutting functionalities u channel roll forming machine manufacturers.

In addition to their efficiency and accuracy, U-channel roll forming machines are also known for their durability and reliability. They are built to withstand the rigors of continuous operation and are designed to minimize maintenance and downtime, ensuring consistent production output over time.

When choosing a U-channel roll forming machine manufacturer, it is important to consider factors such as the machine's production capacity, speed, flexibility, and overall quality. It is also advisable to look for manufacturers with a proven track record of delivering high-quality machines and excellent customer support.

In conclusion, U-channel roll forming machines are indispensable tools for the manufacturing industry, offering a fast, efficient, and cost-effective way to produce U-channel components. By selecting a reputable manufacturer and investing in a high-quality machine, businesses can streamline their production processes and achieve superior results in their U-channel manufacturing operations.

u channel roll forming machine manufacturers.

In addition to their efficiency and accuracy, U-channel roll forming machines are also known for their durability and reliability. They are built to withstand the rigors of continuous operation and are designed to minimize maintenance and downtime, ensuring consistent production output over time.

When choosing a U-channel roll forming machine manufacturer, it is important to consider factors such as the machine's production capacity, speed, flexibility, and overall quality. It is also advisable to look for manufacturers with a proven track record of delivering high-quality machines and excellent customer support.

In conclusion, U-channel roll forming machines are indispensable tools for the manufacturing industry, offering a fast, efficient, and cost-effective way to produce U-channel components. By selecting a reputable manufacturer and investing in a high-quality machine, businesses can streamline their production processes and achieve superior results in their U-channel manufacturing operations. Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products