manual c purlin forming machine factory

The Manual C Purlin Forming Machine A Comprehensive Overview

In the realm of metal fabrication, the manual C purlin forming machine has carved a niche for itself, primarily because of its efficiency and precision in producing C-shaped purlins used in various construction applications. This article delves into the functionality, benefits, and considerations regarding the use of manual C purlin forming machines in the factory setting.

Understanding Purlins

Purlins are horizontal structural members that support roof decking or sheathing in a building. They are crucial in providing structural stability and are commonly employed in commercial and industrial construction, including warehouses, factories, and agricultural buildings. The C-shaped purlin is favored for its strength-to-weight ratio and versatility in design, making it ideal for load-bearing applications.

The Manual C Purlin Forming Machine Functionality

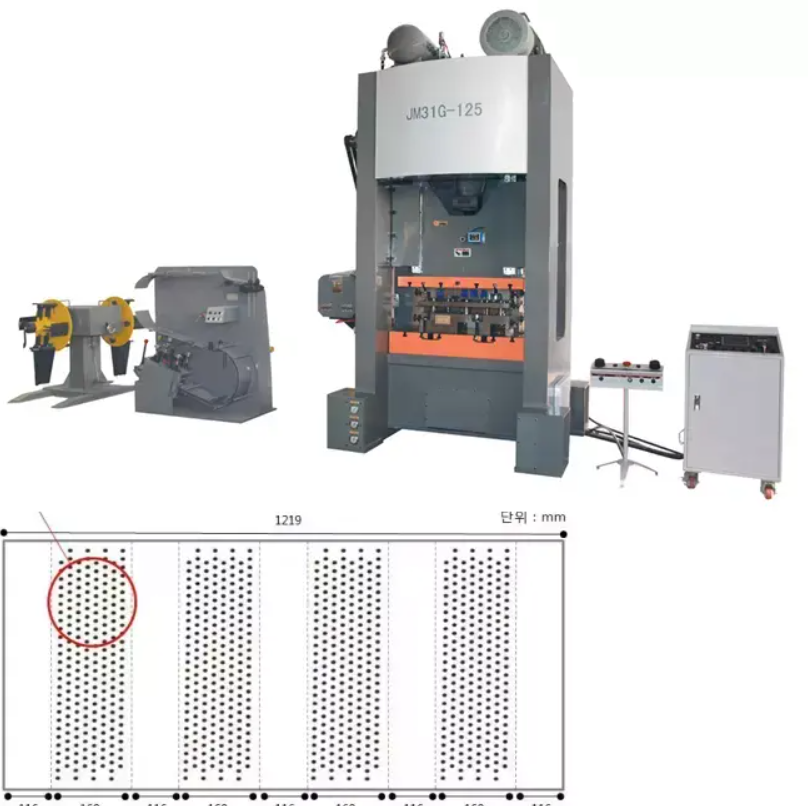

A manual C purlin forming machine typically operates through a series of rollers that shape flat metal strips into the desired C profile. The process begins with feeding flat steel sheets into the machine, which then passes them through a series of rollers. These rollers gradually bend and shape the metal into the final C profile. The manual aspect of the machine means that operators must adjust settings and dimensions as needed, often using levers or manual controls to feed the material.

This machine can handle a variety of materials, including galvanized steel and aluminum, which not only enhances its versatility but also ensures that users can select the best material suited for their specific applications. The output is usually customizable in terms of length and thickness, giving manufacturers immense flexibility in production.

Advantages of Manual C Purlin Forming Machines

1. Cost-Effectiveness Manual machines are often less expensive to purchase and operate compared to their automated counterparts. This makes them an excellent choice for small to medium-sized enterprises that may have budget constraints.

2. Simplicity of Operation The manual nature of these machines allows operators to quickly learn how to use the equipment, facilitating a smoother onboarding process for new workers.

3. Customization With manual controls, operators can easily adjust the dimensions of the purlins, allowing for quick responses to changing project specifications or custom orders.

manual c purlin forming machine factory

5. Less Maintenance Manual machines typically have fewer parts than automated systems, which results in less potential for mechanical failure and easier maintenance routines.

Considerations When Using a Manual C Purlin Forming Machine

While the advantages are substantial, there are also some considerations to keep in mind

1. Labor-Intensive Manual operation can lead to fatigue, especially during large-scale productions. It may also require skilled labor to ensure consistent quality.

2. Production Speed Compared to automated machines, manual forming machines may have a slower production rate. For businesses that need to fulfill high-volume orders quickly, this could be a limiting factor.

3. Quality Control Ensuring consistent quality requires careful monitoring and skilled labor, as manual adjustments may vary between operators.

4. Physical Space Although compact, these machines still require a designated area in the factory and should be situated in a space that allows for efficient workflow.

Conclusion

The manual C purlin forming machine represents a significant tool in metal fabrication, especially for businesses seeking a cost-effective, versatile, and simple solution for producing high-quality C purlins. While they come with certain limitations, their benefits make them a popular choice in various construction environments. As industries continue to evolve, manual forming machines remain relevant, providing reliable performance tailored to specific customer needs. For companies focused on precision and customization, investing in a manual C purlin forming machine could very well enhance operational efficiency and product quality.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025