machine to make metal roofing factories

The Rise of Machine Automation in Metal Roofing Factories

In recent years, the demand for metal roofing has surged significantly due to its durability, energy efficiency, and aesthetic appeal

. This increase in demand has prompted the roofing industry to seek innovative solutions for higher production capacity and efficiency, leading to the widespread adoption of machine automation in metal roofing factories.Traditionally, metal roofing production involved extensive manual labor, which not only made the process time-consuming but also introduced variability in quality. However, with the advent of advanced machinery, manufacturers can now produce high-quality metal roofing materials with greater speed and consistency. Automated machines are capable of handling various tasks, from cutting and shaping metal sheets to applying coatings and assembling final products.

One of the most significant innovations in this field is the introduction of Computer Numerical Control (CNC) machines. These machines are programmed to perform precise, repetitive tasks with minimal human intervention. This technological leap ensures that each piece of roofing is cut to exact specifications, drastically reducing waste and improving overall material utilization. Moreover, the integration of CNC technology allows manufacturers to quickly adjust production to accommodate different designs and sizes, making them highly adaptable to market trends.

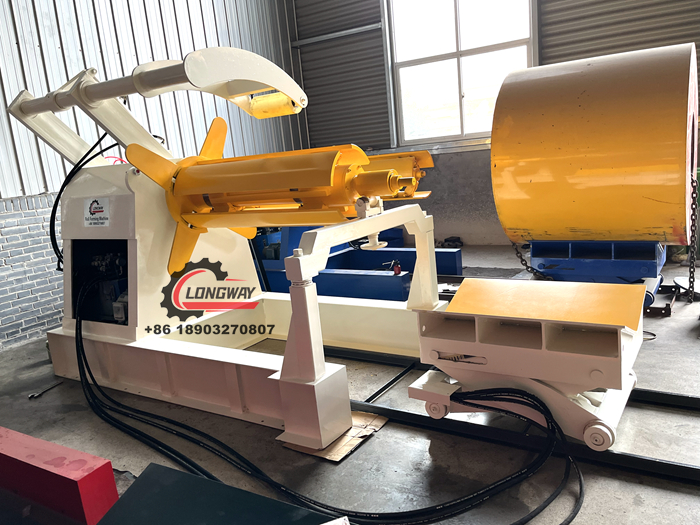

Another essential advancement is the use of roll-forming machines. These machines continuously shape metal sheets into desired profiles, such as standing seam or corrugated structures, by passing them through a series of rollers. This process not only speeds up production but also creates strong, uniform products that meet construction standards. Roll-forming lines can often be customized to produce a variety of profiles, allowing roofing companies to diversify their offerings without significant lead time.

machine to make metal roofing factories

In addition to improving productivity, the automation of metal roofing factories enhances workplace safety. By minimizing manual handling and reducing the need for workers to operate in potentially hazardous environments, companies can create safer work conditions. This transition also allows factory workers to focus on monitoring machinery and quality control, further streamlining the production process.

Furthermore, advancements in robotics and artificial intelligence are beginning to play a role in the metal roofing industry. Automated guided vehicles (AGVs) are increasingly being used to transport materials within factories, further enhancing efficiency. AI-driven systems can analyze production data in real time to identify bottlenecks and optimize workflows, ensuring that factories operate at peak efficiency.

As the construction industry continues to evolve towards greener, more sustainable practices, machine automation in metal roofing factories stands out as a pivotal development. Automated systems can lead to more efficient use of materials and reduced energy consumption in production, aligning with environmental goals and contributing to the overall sustainability of the construction sector.

In conclusion, the use of advanced machines in metal roofing factories marks a significant transformation in how roofing materials are produced. By leveraging technology, manufacturers can improve efficiency, safety, and quality while simultaneously meeting the growing demand for sustainable building solutions. As automation continues to evolve, it promises to further revolutionize the industry, paving the way for a more innovative and efficient future in metal roofing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025