machine to make metal roofing

The Rise of Machines in Metal Roofing Production

In the contemporary construction landscape, the efficient production of roofing materials is paramount, with rising demand for durability and aesthetic appeal. One significant solution to meet this need is the incorporation of advanced machinery in the manufacture of metal roofing systems. This article delves into the various machines used in metal roofing production, their benefits, and the overall impact on the industry.

Understanding Metal Roofing

Metal roofing has gained popularity due to its longevity, energy efficiency, and minimal maintenance requirements. Common materials employed in metal roofing include steel, aluminum, copper, and zinc. These materials are highly durable, outperforming traditional asphalt shingles in both lifespan and resilience against harsh weather conditions. However, the demands of the building industry necessitate efficient production processes, which come from the integration of machines in manufacturing.

Types of Machines Used in Metal Roofing Production

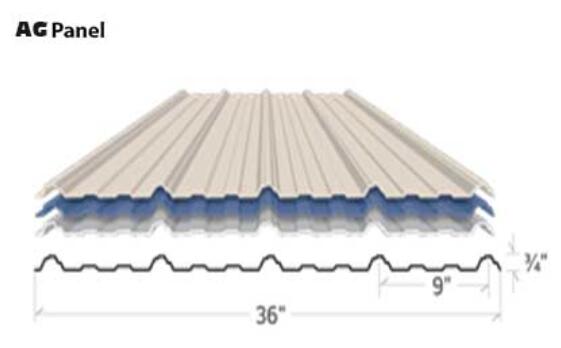

1. Roll Forming Machines Roll forming is a continuous bending process that transforms flat metal sheets into specific profiles. This machine utilizes a series of rollers to shape the metal into roofing panels, ensuring consistent dimensions and eliminating waste. The precision and speed of roll forming machines allow manufacturers to produce large quantities of metal roofing components quickly, making them a cornerstone of roofing production.

2. Cut-to-Length Machines Once metal sheets are roll-formed, cut-to-length machines ensure that they are cut to the precise lengths required for installation. This machinery enhances efficiency by automating what would otherwise be a labor-intensive process. With advanced sensors and controls, these machines can adapt to various sizes and specifications, catering to diverse projects.

3. Slitting Machines Slitting machines are essential for transforming large rolls of metal into narrower strips that can be used for specific roofing profiles. These machines ensure clean cuts and uniform widths, which are critical for panel interlock and overall structural integrity. The increased precision offered by slitting machines diminishes potential errors, thus enhancing the quality of the final product.

machine to make metal roofing

4. Insulation Machines As the demand for energy-efficient roofing grows, insulation machines play a vital role in incorporating insulation materials into the metal panels. These machines ensure that insulation is seamlessly integrated, providing better thermal efficiency and contributing to reduced energy costs for residential and commercial buildings alike.

5. Automatic Welding Machines For some types of metal roofing, especially those involving seams and overlaps, welding machines are crucial. Automatic welding ensures strong, watertight bonds between panels. With advancements in technology, these machines can execute complex welds with precision, enhancing the durability of the roofing system.

6. Coating Machines The final finish of metal roofing is critical for aesthetics and protection against corrosion. Coating machines apply protective layers, such as paint or galvanizing, which shield the metal from the elements and enhance its lifespan. Such machines can execute various finishes, ranging from matte to glossy, catering to diverse consumer preferences.

Benefits of Machine Integration in Metal Roofing Production

The incorporation of machines in metal roofing production remarkably boosts efficiency, consistency, and quality. Automation minimizes human error and speeds up production times, which is critical for meeting project deadlines. Additionally, these machines require less manual labor, reducing labor costs and allowing workers to focus on other skilled tasks.

Moreover, with advances in technology, many of these machines come equipped with smart capabilities, enabling real-time monitoring and data collection. Such insights can lead to improved production processes, reduced waste, and optimized operations, making companies more competitive in the marketplace.

Conclusion

The evolution of machines in the manufacturing of metal roofing systems has revolutionized the construction industry. As demand for durable and energy-efficient roofing options continues to rise, the reliance on advanced machinery will only grow. By enhancing efficiency, quality, and cost-effectiveness, these machines play a pivotal role in shaping the future of building materials. As we move forward, the integration of technology in manufacturing will undoubtedly continue to elevate standards in both metal roofing and the broader construction industry, paving the way for innovative solutions that meet the needs of modern architecture.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025