Equipment Solutions for Roofing Sheet Manufacturing Company

Innovative Machines for Roofing Sheet Manufacturing Transforming the Industry

In the ever-evolving construction sector, efficiency and precision are paramount, especially when it comes to the production of roofing materials. The roofing sheet industry has experienced significant changes over the years, thanks largely to the introduction of advanced machines designed specifically for this purpose. These machines not only enhance production capabilities but also improve the overall quality of roofing sheets.

Roofing sheets are critical components in constructing durable and aesthetically pleasing buildings. Traditionally, roofing sheets were manufactured using manual processes that were time-consuming and labor-intensive. However, with the advent of modern technology, the introduction of fully automated machines has revolutionized the way roofing sheets are produced. These machines offer faster production rates, reduced labor costs, and improved quality control.

Innovative Machines for Roofing Sheet Manufacturing Transforming the Industry

Another vital machine in this sector is the cutting machine, which plays an essential role in ensuring the roofing sheets are cut to precise dimensions. Accuracy in cutting is crucial to maintain uniformity and quality across batches. Modern cutting machines are equipped with advanced sensors and controls that ensure each sheet is tailored to the exact specifications required by clients, thereby reducing the risk of errors that can result in costly material wastage.

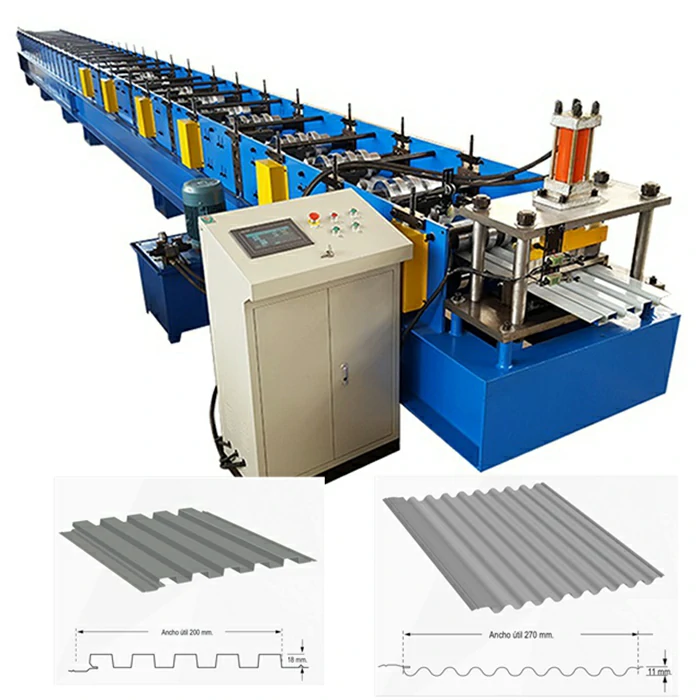

machine for roofing sheet company

In addition to these, the painting and coating machines have also become integral to the roofing sheet manufacturing process. These machines apply protective coatings that enhance the durability and appearance of the sheets. By using high-quality paints and coatings, manufacturers can ensure that their roofing products withstand harsh weather conditions, thereby extending their lifespan. The machines also allow for various finishes and colors, providing customers with a range of options to choose from, which is vital in a competitive market.

Moreover, advancements in technology have led to the development of computer-controlled machines that streamline the entire manufacturing process. These machines can be programmed to execute a series of operations without manual intervention, allowing for a more efficient workflow. The integration of software systems enables manufacturers to monitor production in real-time, optimizing efficiency and ensuring high-quality output.

The shift towards automation and modern machinery is not just about improving production; it also emphasizes sustainability. Many manufacturers are now investing in energy-efficient machines that reduce energy consumption during the production process, aligning with global sustainability goals. These efforts not only contribute to lower operational costs but also resonate with environmentally conscious consumers.

In conclusion, the introduction of innovative machines in the roofing sheet manufacturing sector has brought about transformative changes. From roll forming and cutting to painting and coating, automation has improved production efficiency, reduced material wastage, and enhanced product quality. As technology continues to advance, it is likely that we will see even more sophisticated machines entering the market, further pushing the boundaries of what is possible in roofing sheet production. These advancements not only benefit manufacturers but also provide consumers with high-quality, durable roofing solutions that cater to a diverse range of needs. As the industry continues to evolve, embracing these innovations will be key to staying competitive in the dynamic construction landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025