Advanced Equipment for Roofing Sheet Production and Manufacturing Solutions

The Advancements in Machinery for Roofing Sheet Companies

In today's fast-paced construction industry, the demand for high-quality roofing materials has surged. Roofing sheet companies play a critical role in meeting this demand, and to stay competitive, they must invest in advanced machinery. This article explores the importance of machinery in roofing sheet production, the types of machines used, and the innovations that have shaped the industry.

The Importance of Machinery

Machinery is a cornerstone of efficiency and quality in the roofing sheet manufacturing process. As companies strive to produce durable and visually appealing roofing materials, the right equipment can significantly enhance production capabilities. High-performance machines not only improve output but also ensure consistent quality, reducing waste and minimizing production costs. For roofing sheet manufacturers, investing in modern machinery is not just a matter of choice but a necessity to meet market expectations and regulatory standards.

Types of Machines Used

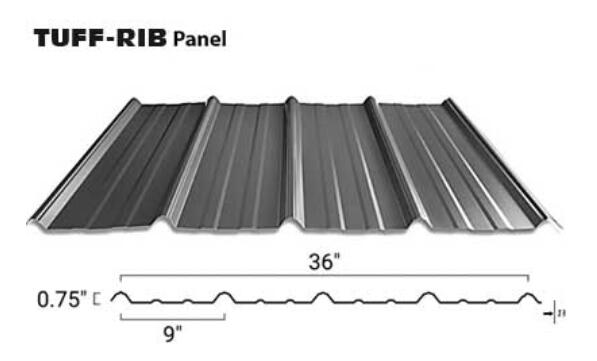

1. Roll Forming Machines These machines are fundamental in the production of metal roofing sheets. Roll forming involves the continuous bending of metal sheets into specific profiles by passing them through a series of rollers. This process allows roofing sheet companies to create a wide variety of shapes and sizes, catering to diverse customer needs. The precision of roll forming ensures that each sheet adheres to strict tolerances, resulting in high-quality end products.

2. Cut-to-Length Machines Once the roofing sheets are formed, they often need to be cut to specific lengths. Cut-to-length machinery automates this process, providing accurate cuts that help maintain uniformity in the final products. This equipment can handle various thicknesses and materials, making it a versatile addition to a roofing sheet company's production line.

3. Slitting Machines For manufacturers producing narrower sheets or strips, slitting machines are essential. These machines cut large rolls of metal into narrower widths, allowing for further processing and customization. With advancements in slitting technology, companies can achieve tighter tolerances and faster processing times, which directly contribute to an increase in productivity.

machine for roofing sheet company

4. Coating Machines To enhance the durability and aesthetic appeal of roofing sheets, many companies apply protective coatings. Coating machines automate this vital process, ensuring an even application of paints, galvanization, or other protective layers. The right coating can extend the lifespan of roofing materials and improve their resistance to weather elements, making them more attractive to customers.

Innovations Shaping the Industry

The roofing sheet manufacturing landscape is continually evolving, driven by technological advancements. Some notable innovations include

- Automation and Robotics Many companies are integrating automation into their production lines. Automated systems can perform repetitive tasks with greater precision and speed than human laborers. This not only boosts production efficiency but also reduces the risk of human error. Robots are increasingly used for loading, unloading, and assembling products, allowing human workers to focus on more complex tasks.

- Computer Numerical Control (CNC) CNC technology has revolutionized how roofing sheet companies operate. CNC machines allow for precise programming of cutting and forming processes, enabling manufacturers to produce complicated designs consistently. The flexibility afforded by CNC technology means that companies can quickly adapt to changing market demands and customer preferences without significant downtime.

- Sustainability Initiatives With a growing emphasis on sustainability, machine manufacturers are now designing eco-friendly equipment that minimizes waste and energy consumption. Innovations such as energy-efficient motors, regenerative braking systems, and systems that recover scrap material for reuse are becoming standard in the industry.

Conclusion

As the construction industry continues to grow and evolve, roofing sheet companies must leverage advanced machinery to remain competitive. By investing in state-of-the-art equipment, these companies can enhance production efficiency, maintain stringent quality standards, and respond swiftly to market demands. Embracing technology and innovation is not just an opportunity for growth; it is essential for survival in an increasingly demanding marketplace. The future of roofing sheet production lies in the hands of those who recognize the value of machinery and are willing to adapt to the ever-changing landscape of the construction industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025