Feb . 19, 2025 07:00

Back to list

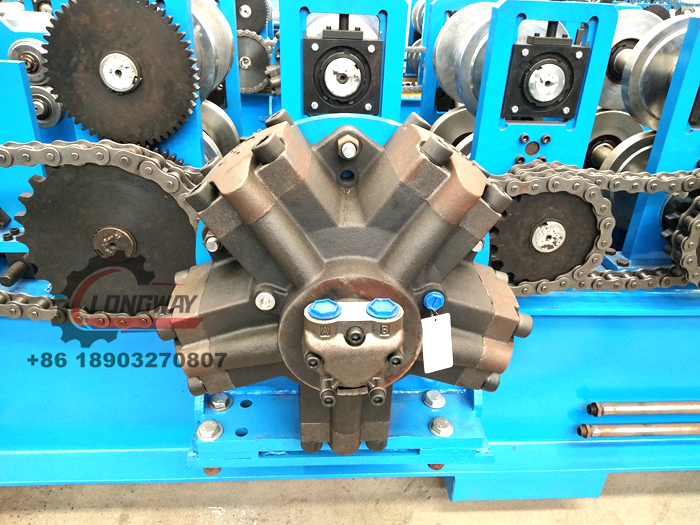

lingt steel frame roll forming machine

Light steel frame roll forming machines have revolutionized the construction industry, merging cutting-edge technology with unprecedented precision and efficiency. The integration of these machines has not only streamlined the construction process but also enhanced the quality and durability of the structures built. This advanced machinery is designed to automate the production of light steel frames, catering to the demands of modern architectural projects that seek sustainability and resilience.

Operators of these machines must possess a deep understanding of both the machinery and the materials being used. Experience and expertise in the use of light steel frame roll forming machines are essential for optimizing their output and ensuring that each build adheres to regulatory standards. Professionals who are well-versed in these processes can preemptively address potential technical issues, thus maintaining productivity and machine efficacy. Authoritativeness in this field comes from an understanding of both the advantages and limitations of light steel frame construction. While offering numerous benefits, steel framing can pose challenges in terms of thermal conductivity and sound insulation. However, industry leaders consistently innovate, integrating new materials and techniques to mitigate these potential drawbacks. An expert approach would involve ongoing research and adaptation to incorporate these advancements into the roll forming process, ensuring the construction remains state-of-the-art and compliant with contemporary standards. Trustworthiness in the context of light steel frame roll forming machinery lies in the ability to consistently deliver high-quality products. Suppliers and manufacturers must adhere to stringent quality control processes and provide comprehensive training and support to their machine operators. This guarantees that each component produced meets the required safety standards and contributes to the overall strength and safety of the final structure. In conclusion, the role of light steel frame roll forming machines in modern construction cannot be overstated. Combining automation with precision engineering, these machines facilitate efficient, cost-effective, and sustainable construction practices. To optimize these benefits, professionals must leverage their expertise and maintain an authoritative knowledge base, ensuring continuous improvement and adaptation in an ever-evolving industry. Through a commitment to quality and innovation, these machines will remain integral to the future of construction, meeting the demands of increasingly complex architectural designs while adhering to the highest standards of safety and durability.

Operators of these machines must possess a deep understanding of both the machinery and the materials being used. Experience and expertise in the use of light steel frame roll forming machines are essential for optimizing their output and ensuring that each build adheres to regulatory standards. Professionals who are well-versed in these processes can preemptively address potential technical issues, thus maintaining productivity and machine efficacy. Authoritativeness in this field comes from an understanding of both the advantages and limitations of light steel frame construction. While offering numerous benefits, steel framing can pose challenges in terms of thermal conductivity and sound insulation. However, industry leaders consistently innovate, integrating new materials and techniques to mitigate these potential drawbacks. An expert approach would involve ongoing research and adaptation to incorporate these advancements into the roll forming process, ensuring the construction remains state-of-the-art and compliant with contemporary standards. Trustworthiness in the context of light steel frame roll forming machinery lies in the ability to consistently deliver high-quality products. Suppliers and manufacturers must adhere to stringent quality control processes and provide comprehensive training and support to their machine operators. This guarantees that each component produced meets the required safety standards and contributes to the overall strength and safety of the final structure. In conclusion, the role of light steel frame roll forming machines in modern construction cannot be overstated. Combining automation with precision engineering, these machines facilitate efficient, cost-effective, and sustainable construction practices. To optimize these benefits, professionals must leverage their expertise and maintain an authoritative knowledge base, ensuring continuous improvement and adaptation in an ever-evolving industry. Through a commitment to quality and innovation, these machines will remain integral to the future of construction, meeting the demands of increasingly complex architectural designs while adhering to the highest standards of safety and durability.

Latest news

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

Related Products