Feb . 08, 2025 07:46

Back to list

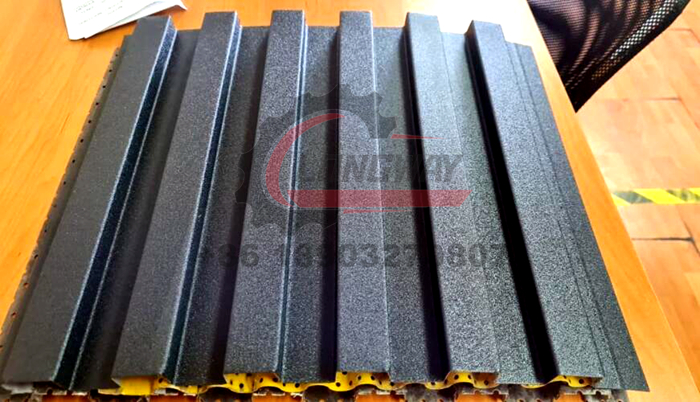

US Metal Roofing Ag and R panel Roll Former

The light steel frame roll forming machine has revolutionized the construction industry with its precision and efficiency, offering an innovative solution for fabricating galvanized steel structures used in a variety of architectural applications. At the heart of this technology lies an advanced system engineered to produce consistent, high-quality outputs while minimizing waste and reducing costs. This article delves deep into the multifaceted benefits of utilizing such machinery, touching on the core aspects that make it indispensable for modern building projects.

In terms of trustworthiness, the reliability and durability of the structures produced by light steel frame roll forming machines play a pivotal role. With rigorous quality control processes integrated into their design, the machines deliver profiles that meet stringent safety and building codes. This assurance of quality is reinforced by comprehensive testing and certification standards that the machines and the outputs consistently meet. The resultant structures are lightweight yet robust, capable of withstanding diverse environmental conditions, thus earning the trust of architects, engineers, and contractors alike. The economic advantages of employing light steel frame roll forming machines extend beyond material savings. They significantly reduce labor costs by streamlining the production process and minimizing the time spent on-site assembly. Quick turnaround times translate into faster project completion, offering a competitive edge in the fast-paced construction industry. Furthermore, the adaptability of these machines to produce various designs and shapes means that builders can cater to diverse customer preferences without the added overhead of multiple machinery setups. Moreover, these machines are increasingly adopting automated technologies, integrating with Industry 4.0 advancements. Automation elevates the production capabilities, providing seamless transitions between different design specifications and enhancing production volumes. It also ensures continuous operation with minimal downtime, further improving the cost-efficiency and profitability for users. In conclusion, the light steel frame roll forming machine stands out as a cornerstone in modern construction and steel fabrication. Its impact is evident not only in the quality and aesthetic aspects of finished structures but also in the efficiencies and environmental considerations it promotes. As the industry continues to evolve with a focus on sustainability and precision, the reliance on such advanced machinery is set to grow, marking it as a crucial investment for forward-thinking construction firms aiming to spearhead innovation and quality in their projects. Investing in a light steel frame roll forming machine is indeed a strategic move, ensuring competitive advantage, operational excellence, and alignment with global construction trends.

In terms of trustworthiness, the reliability and durability of the structures produced by light steel frame roll forming machines play a pivotal role. With rigorous quality control processes integrated into their design, the machines deliver profiles that meet stringent safety and building codes. This assurance of quality is reinforced by comprehensive testing and certification standards that the machines and the outputs consistently meet. The resultant structures are lightweight yet robust, capable of withstanding diverse environmental conditions, thus earning the trust of architects, engineers, and contractors alike. The economic advantages of employing light steel frame roll forming machines extend beyond material savings. They significantly reduce labor costs by streamlining the production process and minimizing the time spent on-site assembly. Quick turnaround times translate into faster project completion, offering a competitive edge in the fast-paced construction industry. Furthermore, the adaptability of these machines to produce various designs and shapes means that builders can cater to diverse customer preferences without the added overhead of multiple machinery setups. Moreover, these machines are increasingly adopting automated technologies, integrating with Industry 4.0 advancements. Automation elevates the production capabilities, providing seamless transitions between different design specifications and enhancing production volumes. It also ensures continuous operation with minimal downtime, further improving the cost-efficiency and profitability for users. In conclusion, the light steel frame roll forming machine stands out as a cornerstone in modern construction and steel fabrication. Its impact is evident not only in the quality and aesthetic aspects of finished structures but also in the efficiencies and environmental considerations it promotes. As the industry continues to evolve with a focus on sustainability and precision, the reliance on such advanced machinery is set to grow, marking it as a crucial investment for forward-thinking construction firms aiming to spearhead innovation and quality in their projects. Investing in a light steel frame roll forming machine is indeed a strategic move, ensuring competitive advantage, operational excellence, and alignment with global construction trends.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products