Lightweight Keel Roll Forming Equipment for Efficient Construction Solutions

Light Keel Roll Forming Machine Revolutionizing Construction and Manufacturing

In the rapidly evolving world of construction and manufacturing, efficiency and precision are paramount. One of the technological advancements that have made significant strides in this field is the light keel roll forming machine. This innovative piece of equipment has transformed the way structural components are produced, offering a blend of speed, accuracy, and versatility.

A light keel roll forming machine is designed to produce lightweight structural components, commonly referred to as keels, which are essential in various construction applications. These keels are primarily used in the construction of lightweight steel frames and partitions, contributing to structures such as residential buildings, commercial spaces, and industrial facilities. The demand for such components has surged, propelled by the increasing need for faster and more efficient building methods.

How Does It Work?

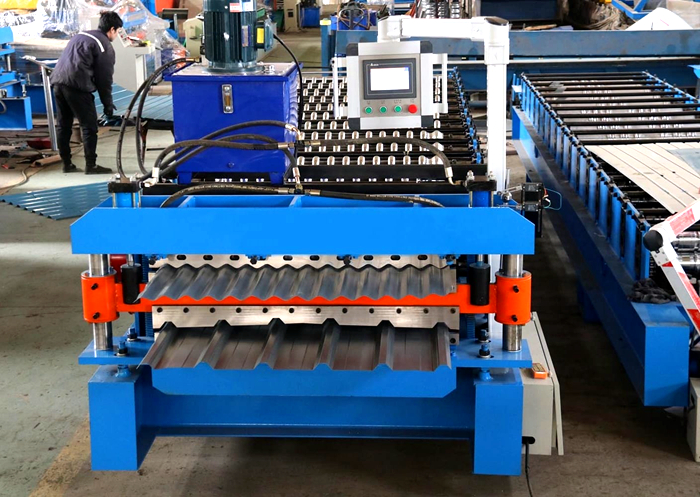

The operation of a light keel roll forming machine involves a series of processes where flat metal strips are gradually shaped into desired profiles through a sequence of rollers. The machine typically consists of a decoiler, a roll-forming station, a cutting unit, and a stacking system.

1. Decoiling The process begins with a decoiler that feeds the flat metal strip into the machine. 2. Roll Forming As the strip passes through a series of specially designed rollers, it is gradually bent and shaped into a predetermined cross-section. 3. Cutting Once the desired shape is achieved, the formed section is cut to the required lengths using a cutting unit, which operates in synchronization with the roll forming process. 4. Stacking Finally, the produced keels are stacked automatically for easy handling and storage.

Benefits of Light Keel Roll Forming Machines

light keel roll forming machine

1. Efficiency The high-speed operation of these machines significantly reduces production time, allowing manufacturers to meet tight deadlines without compromising quality. 2. Precision The roll forming process ensures consistent and accurate dimensions for each keel, which is crucial for structural integrity in construction. 3. Material Utilization Roll forming minimizes waste by optimizing the use of raw materials. The continuous process allows for better material management, reducing costs and environmental impact. 4. Versatility These machines can be easily adjusted to produce a variety of profiles and sizes, making them suitable for diverse applications in the construction industry. 5. Cost-Effectiveness By streamlining production and reducing labor costs, light keel roll forming machines offer an economical solution for manufacturers looking to improve their bottom line.

Applications in the Industry

The versatility of light keel roll forming machines extends beyond traditional applications. They are increasingly being employed in the production of components for high-rise buildings, warehouses, and even temporary structures. Their lightweight nature does not compromise strength, making them ideal for use in seismic zones and areas constrained by weight restrictions.

Moreover, the rise of prefabricated construction methods has further accelerated the demand for light keels. Builders are turning to these machines to create modular and pre-assembled structures that can be quickly assembled on-site, saving time and reducing labor costs while maintaining high-quality standards.

Conclusion

In conclusion, the light keel roll forming machine represents a significant advancement in the construction and manufacturing sectors. Its ability to produce lightweight, precise, and versatile structural components has revolutionized how buildings are constructed today. As the industry continues to evolve, it is likely that these machines will become even more integral to the future of efficient, sustainable construction practices. The blend of technology, efficiency, and innovation embodied in light keel roll forming machines is paving the way for a new era in construction—one that prioritizes speed, quality, and sustainability.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025