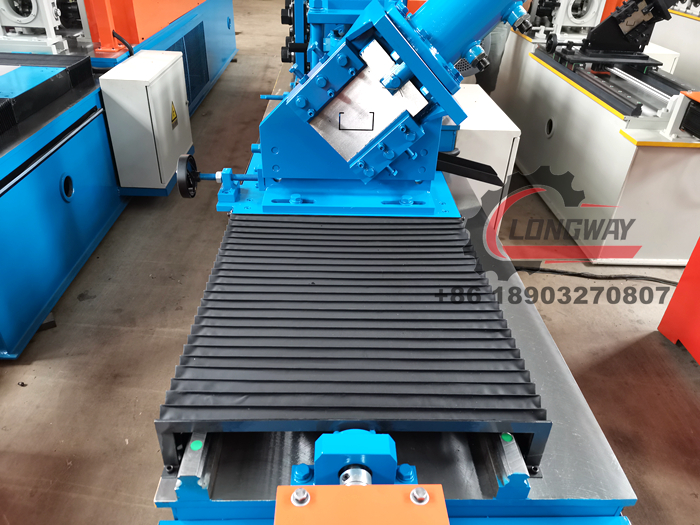

light keel purlin machine

The Light Keel Purlin Machine A Revolution in Metal Fabrication

In the ever-evolving world of construction and manufacturing, the need for precision, efficiency, and adaptability is paramount. One of the most significant innovations in metal fabrication is the light keel purlin machine, a piece of equipment that has transformed how purlins are produced, thus playing a vital role in modern building frameworks. This article delves into the workings, advantages, and applications of light keel purlin machines, showcasing their importance in today's construction industry.

Understanding Light Keel Purlins

Purlins are horizontal structural members used in the construction of roofs and walls. They are typically made from steel and can be classified into various types, including C, Z, and U shapes depending on their application. Light keel purlins, in particular, are designed for use in lighter structures and are ideal for applications where weight savings and material efficiency are critical.

The manufacturing of light keel purlins traditionally involved manual processes or less sophisticated machinery, leading to inconsistencies in dimensions and quality. However, with the advent of the light keel purlin machine, the production process has become automated, allowing for high precision, uniformity, and faster output.

How Light Keel Purlin Machines Work

A light keel purlin machine operates through a process called roll forming. This is a method where flat steel strips are fed into a series of rollers that gradually shape the material into the desired profile. The process involves the following steps

1. Feeding The flat steel sheet is fed into the machine, where it is aligned for precise shaping. 2. Roll Forming The material passes through multiple sets of rollers, which bend it into the specified purlin shape. Each roller performs a unique function in shaping the steel progressively. 3. Cutting Once the desired length is achieved, the machine cuts the purlin to size, ensuring high accuracy. 4. Finishing Some machines also incorporate features for punching holes or adding finishing treatments, which further enhance the functionality of the purlins for specific applications.

This entire process can be completed in a matter of minutes, drastically reducing production times compared to traditional methods.

Advantages of Light Keel Purlin Machines

light keel purlin machine

1. High Precision Automated processes minimize human error, resulting in purlins that meet exact specifications. This consistency is crucial for structural integrity in construction.

2. Efficiency The speed of production allows companies to meet high demand quickly. This efficiency translates into cost savings, making projects more profitable.

3. Material Optimization By cutting and shaping steel with high accuracy, these machines minimize material waste. This not only reduces costs but also benefits the environment by decreasing scrap metal generation.

4. Versatility Light keel purlin machines can produce various profiles and sizes, making them suitable for a wide range of construction applications, including residential, commercial, and industrial buildings.

5. Automation With advances in technology, many light keel purlin machines are equipped with digital controls and automated features that allow for easy operation and adjustments.

Applications in Construction

Light keel purlins are widely utilized in various construction fields

- Warehouse Structures Due to their lightweight nature, they are often employed in warehouse roofs, providing essential support while reducing the overall weight of the structure. - Residential Buildings In modern home construction, light keel purlins can be used in roof framing, allowing for open spaces and minimal support structures. - Industrial Applications Factories and production facilities frequently use light keel purlins for their structural needs due to their cost-effectiveness and strength.

Conclusion

The light keel purlin machine stands at the intersection of technology and traditional construction methods, streamlining the production of essential building components. With its advantages of speed, precision, and material efficiency, this innovative machine has become indispensable in modern construction workflows. As the demand for lightweight and cost-effective building solutions continues to rise, the role of the light keel purlin machine will undoubtedly grow, shaping the future of the construction industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025