Lightweight Cold Roll Forming Machine for Keel Production and Efficiency

Light Keel Cold Roll Forming Machine An Overview

In the ever-evolving world of construction and manufacturing, efficiency, precision, and cost-effectiveness have become paramount. One of the key innovations that address these demands is the light keel cold roll forming machine. This advanced machinery has garnered significant attention due to its ability to produce high-quality, lightweight structural components that are essential in modern construction and industrial applications.

What is a Light Keel Cold Roll Forming Machine?

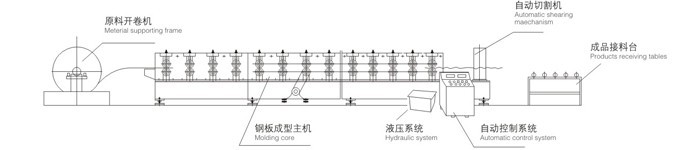

The light keel cold roll forming machine is designed specifically for the production of light gauge steel profiles, commonly referred to as keels, which are extensively used in drywall systems, ceiling installations, and other structural applications. The process involves the continuous bending and shaping of steel strips into desired profiles using a series of rollers. This method is known as cold roll forming, as it shapes the metal at room temperature, which helps maintain the integrity and strength of the material.

Key Features and Benefits

1. Precision Engineering One of the most significant advantages of the light keel cold roll forming machine is its precision. The rollers are finely calibrated to ensure that every profile produced is uniform and meets stringent specifications. This precision is crucial in the construction industry, where even minor deviations can lead to structural issues.

2. High Production Efficiency These machines are known for their high-speed production capabilities. They can produce large quantities of profiles in a short amount of time, which not only enhances productivity but also reduces labor costs. The ability to operate continuously makes them a valuable asset in high-demand manufacturing environments.

3. Material Optimization The design of the cold roll forming process allows for the efficient use of raw materials. By minimizing waste during the shaping process, manufacturers can optimize their material usage and reduce overall costs. This is particularly important in an era where sustainability and resource conservation are increasingly emphasized.

4. Versatility Light keel cold roll forming machines are highly versatile. They can be customized to produce different profile shapes and sizes based on the specific needs of a project. This adaptability makes them suitable for various applications, from residential construction to commercial projects and industrial facilities.

light keel cold roll forming machine

5. Enhanced Strength-to-Weight Ratio The use of light gauge steel in conjunction with advanced forming techniques results in profiles that have an excellent strength-to-weight ratio. This is particularly advantageous in construction, where lighter materials can lead to lower structural loads, reduced foundation requirements, and overall cost savings.

Applications in Construction

The applications of light keel cold roll forming machines in construction are diverse. They are commonly used to produce metal framing for interior walls and ceilings, providing support for drywall systems. Furthermore, these machines are instrumental in creating building components such as door frames, window frames, and trusses.

In addition to their structural applications, light keels are also utilized in partitions and modular construction, allowing for faster assembly and flexibility in design. The lightweight nature of these profiles contributes to minimizing shipping costs and makes transportation easier, which is a critical factor in many construction projects.

Future Trends

As the construction industry continues to evolve, the demand for lightweight, strong, and cost-effective building solutions is expected to grow. The light keel cold roll forming machine is likely to see further innovations, including the integration of automation and smart technology to enhance productivity and user experience. Advanced features such as real-time monitoring, predictive maintenance, and enhanced design software will contribute to the machine's efficiency and accuracy.

Conclusion

In conclusion, the light keel cold roll forming machine represents a significant advancement in the construction and manufacturing sectors. Its ability to produce high-quality, lightweight metal profiles with precision and efficiency makes it an essential tool for modern construction practices. As the industry continues to prioritize sustainability and innovative solutions, this machinery will undoubtedly play a pivotal role in shaping the future of building and construction, reinforcing its importance in delivering effective and reliable structural components. The versatility, efficiency, and adaptability of light keel cold roll forming machines underscore their critical role in meeting the demands of a rapidly changing industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025