light gauge steel keel roll forming machine

Understanding Light Gauge Steel Keel Roll Forming Machines

In recent years, the construction industry has increasingly embraced innovative manufacturing technologies, one of which is the light gauge steel keel roll forming machine. This sophisticated piece of equipment has transformed the way builders utilize light gauge steel, offering numerous advantages in terms of efficiency, precision, and sustainability.

What is Light Gauge Steel?

Light gauge steel is defined as steel that is less than 3.2 mm thick. It is commonly used in the construction of walls, roofs, and floors. The material is favored for its strength-to-weight ratio, affordability, and ease of installation. Light gauge steel has also gained popularity due to its resistance to fire, pests, and rot, making it a preferred choice in various building applications.

The Role of Roll Forming Machines

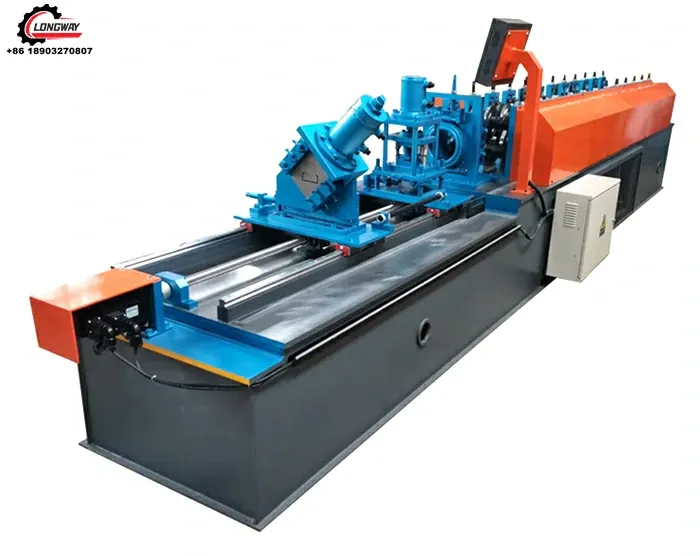

Roll forming is a continuous bending operation in which a long strip of metal is gradually shaped into the desired profile. A light gauge steel keel roll forming machine consists of several rollers that progressively shape the steel into specific profiles as it passes through the machine. This process allows for the efficient production of complex shapes and sizes, making it ideal for constructing steel keels used in various building frameworks.

Key Features of Light Gauge Steel Keel Roll Forming Machines

1. Precision Engineering Modern roll forming machines are designed for high precision. The rollers are crafted to ensure accurate dimensions, minimizing waste and maximizing material utilization.

2. Speed and Efficiency These machines can produce large quantities of product at high speeds. This efficiency translates to reduced labor costs and faster project timelines, making them an attractive option for builders.

light gauge steel keel roll forming machine

3. Versatility A light gauge steel keel roll forming machine can create a variety of profiles and shapes, including tracks, studs, and joists, making it a versatile addition to any construction line.

4. Automation Many contemporary machines come equipped with automated controls, enabling easy adjustments to production settings. This feature enhances operational efficiency and allows for quick changes in product design without extensive downtime.

5. Sustainability The use of light gauge steel is often touted as an environmentally friendly option, as steel is 100% recyclable. By utilizing advanced roll forming technology, manufacturers can minimize waste and energy consumption, contributing to greener building practices.

Applications of Light Gauge Steel Keel Roll Forming Machines

These machines find applications in various sectors, including residential construction, commercial building, and industrial projects. They are particularly advantageous in projects that require lightweight yet sturdy framing materials. Additionally, light gauge steel is extensively used in modular construction, where speed and precision are critical for the success of the project.

Conclusion

The light gauge steel keel roll forming machine represents a significant advancement in manufacturing technology within the construction industry. With its ability to produce high-quality steel components efficiently, it streamlines construction processes and plays a vital role in modern building practices. As the demand for sustainable and efficient construction solutions continues to grow, the adoption of roll forming technology is likely to expand, providing builders with the tools they need to meet the challenges of contemporary construction.

In summary, the light gauge steel keel roll forming machine is not just a tool; it is a catalyst for innovation, promoting faster, more efficient, and environmentally friendly building practices. Whether for residential or commercial applications, the integration of this technology will undoubtedly shape the future of construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025