Leading Manufacturers of Stud and Track Roll Forming Machines for Efficient Construction Solutions

The Evolution of Stud and Track Roll Forming Machines

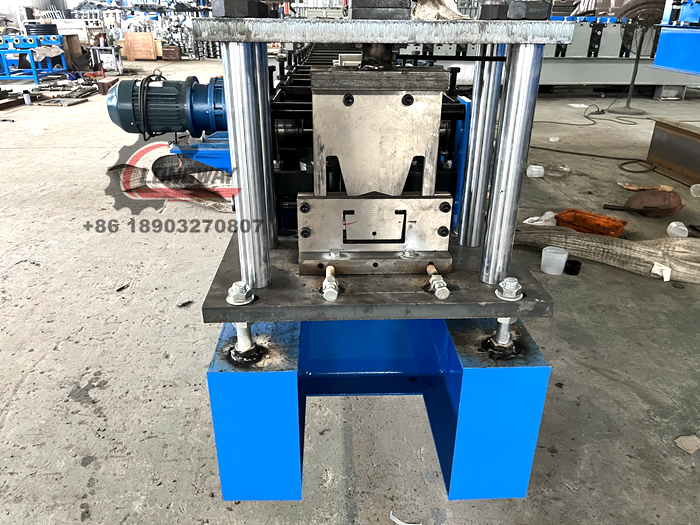

In the ever-evolving landscape of manufacturing technology, stud and track roll forming machines have emerged as critical tools for industries involved in metal fabrication. These machines are designed to produce C-shaped and U-shaped metal tracks essential for constructing metal stud framing systems, which are widely used in commercial and residential buildings. As the demand for efficient, high-quality construction materials continues to rise, the role of stud and track roll forming machine companies has become increasingly significant.

Understanding Roll Forming Technology

Roll forming is a continuous bending operation in which a long strip of metal is processed through a series of rollers to achieve a desired cross-section. This technology is particularly advantageous for producing long lengths of identical parts with superior precision. The stud and track roll forming machines utilize this process to create metal framing components that meet industry standards.

The machines typically feature an automatic feeding system, precision rollers, and cutting mechanisms, allowing for quick setup and minimal waste. This makes them ideal for high-volume production runs. Furthermore, advancements in technology have led to the incorporation of computer numerical control (CNC), enhancing accuracy and enabling the production of complex profiles in a cost-effective manner.

Key Features of Stud and Track Roll Forming Machines

Stud and track roll forming machines come with several features that enhance their utility in the manufacturing process

2. High Speed and Efficiency These machines are capable of high-speed production, enabling manufacturers to meet tight deadlines and manage high-demand orders.

stud and track roll forming machine companies

3. Quality Control Advanced features like automatic gauges and inspection systems ensure that each piece meets stringent quality standards, reducing the likelihood of defects.

4. Customization Many companies offer bespoke solutions tailored to the specific requirements of their clients, allowing for greater flexibility in design and production.

The Role of Leading Companies in the Industry

Several companies have established themselves as leaders in the stud and track roll forming machine market. These companies invest heavily in research and development, leading to the continuous improvement of machine efficiency and product quality. They also provide comprehensive support services, including training for operators, maintenance services, and spare parts supplies, to ensure that their clients can operate the machines smoothly and effectively.

Furthermore, industry leaders often participate in trade shows and exhibitions, showcasing their latest innovations and fostering connections within the construction and manufacturing industries. Their presence not only emphasizes their commitment to quality and innovation but also helps create benchmarks for emerging companies in the market.

Conclusion

As the construction industry continues to evolve, the demand for high-quality, efficient manufacturing processes increases. Stud and track roll forming machines play a pivotal role in meeting these demands by providing reliable solutions for producing metal framing components. With the continuous advancements in technology and the commitment of leading companies to quality and innovation, the future of stud and track roll forming machinery looks promising. Manufacturers that recognize the value of these machines will be better equipped to compete in a rapidly changing industry, contributing to safer and more efficient construction practices worldwide.

In summary, the stud and track roll forming machine sector is not only a testament to the ingenuity of manufacturing technology but also a critical component in the broader construction industry, paving the way for innovations that enhance efficiency, quality, and sustainability in building practices.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025