Leading Manufacturers of Roll Forming Line Machines for Efficient Metal Fabrication Solutions

The Evolution and Importance of Roll Forming Line Machine Manufacturers

In the modern industrial landscape, the demand for precision-engineered components is at an all-time high. This demand has sparked the growth of specialized manufacturers who focus on various forming techniques, one of the most significant being roll forming. Roll forming is a continuous bending operation where a long strip of metal is passed through successively arranged rollers to achieve the desired cross-section shape. The process is not only efficient but also allows for high-volume production of uniform products.

Understanding Roll Forming

Roll forming machines are designed to produce complex shapes from metal sheets or strips with exceptional precision. The process begins with feeding a flat metal strip into a series of rollers that gradually shape it into the desired profile, which can include everything from simple angles to intricate metal components used in construction, automotive, and appliance industries. One of the key advantages of roll forming is its ability to produce long lengths of components with minimal waste, making it both an economical and environmentally friendly option.

The Role of Manufacturers

Roll forming line machine manufacturers play a crucial role in this sector. They are responsible for designing and building the machinery that will ultimately drive the efficiency and precision of the roll forming process. These manufacturers must stay ahead of technological advancements and industry demands, constantly innovating their machinery to meet higher production standards.

Several manufacturers specialize in providing customized roll forming solutions tailored to specific customer needs. This can include modifications in the machine design, adjusting the speed of production, or adding further capabilities such as punching, notching, or cutting. By providing bespoke solutions, these manufacturers ensure that their customers can produce parts that meet their unique specifications and requirements.

Technological Advancements

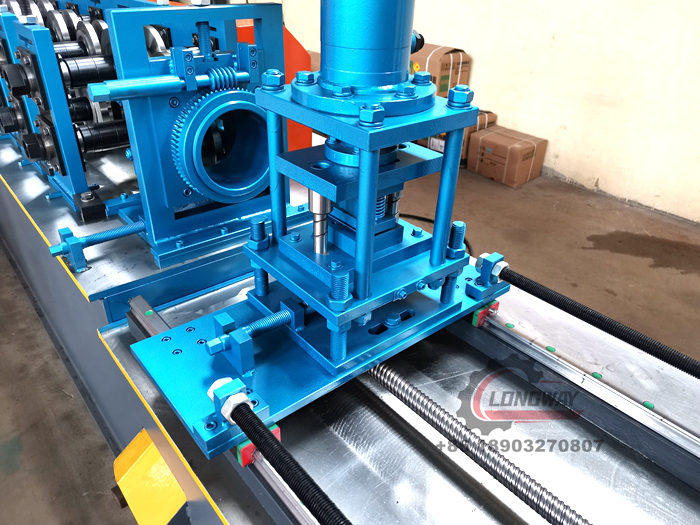

roll forming line machine manufacturers

As industries continue to evolve, so too do the technologies used in roll forming. Modern roll forming machines are increasingly equipped with advanced features such as computer numerical control (CNC) systems, which allow for greater precision and repeatability in production. Industry 4.0 has also introduced the concept of smart factories, where equipment is interconnected and can communicate, thereby optimizing production processes.

Moreover, automation has significantly improved the efficiency of roll forming lines. Automated material handling systems can quickly and accurately feed materials into the roll forming machines, reducing labor costs and minimizing the risk of human error. The integration of robotics in the roll forming process can further enhance flexibility and productivity.

Global Market Trends

In the global market, the demand for roll forming line machines is driven by various factors including the growing construction industry, rising automotive production, and the increasing need for energy-efficient solutions. Countries such as China, Germany, and the United States are leading in the manufacturing of roll forming machines, exporting their technology worldwide.

Sustainability is another trend driving the evolution of roll forming machines. Manufacturers are now focusing on developing machinery that reduces energy consumption and material wastage, aligning with global goals for sustainable development.

Conclusion

In summary, roll forming line machine manufacturers are pivotal in the production of precision-engineered components that are critical to modern industries. As technology continues to advance and industry demands evolve, these manufacturers must remain at the forefront of innovation, offering efficient and sustainable solutions to meet the diverse needs of their customers. The role of these manufacturers is not just to create machinery; they are integral partners in driving efficiency, precision, and sustainability in the ever-evolving world of manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025