Leading Manufacturers of Advanced Double Layer Forming Machines for Efficient Production Solutions

Double Layer Forming Machine Manufacturer Unlocking the Potential of Modern Manufacturing

In the realm of manufacturing, efficiency and versatility are key drivers of success, especially in the production of roofing and wall panels. One piece of equipment that has gained significant attention in recent years is the double layer forming machine. This innovative machine allows manufacturers to produce two different profiles in one continuous production line, maximizing productivity while minimizing costs. As the demand for such machines continues to rise, various manufacturers have emerged, each offering unique solutions that cater to diverse industrial needs.

What is a Double Layer Forming Machine?

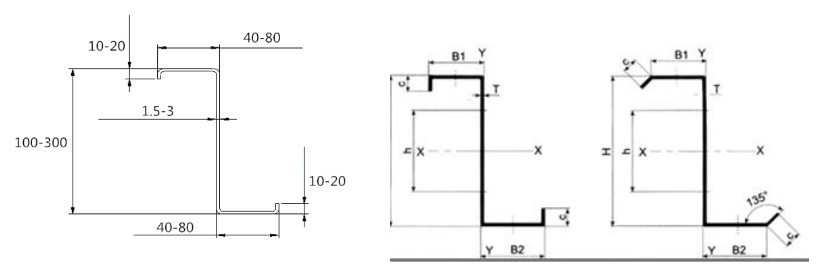

A double layer forming machine is designed to manufacture two different types of metal sheets simultaneously. This is achieved through a dual-layer roll forming system that alternates between two sets of forming rolls, allowing for the creation of two distinct profiles without the need for switching out equipment. Typically used for producing roofing sheets, wall panels, and other structural components, these machines streamline the production process, saving time and resources.

Advantages of Double Layer Forming Machines

The primary advantage of double layer forming machines lies in their efficiency. By producing two profiles at once, manufacturers can significantly increase their output without the need for additional machinery or labor. This not only cuts down on production time but also reduces operational costs, making it a cost-effective solution for businesses of all sizes.

Moreover, the flexibility offered by these machines enables manufacturers to respond quickly to changing market demands. With the ability to switch between different profiles with minimal setup time, businesses can adapt their production lines to meet customer specifications without extensive downtime. This adaptability is crucial in industries where trends and requirements can shift rapidly.

double layer forming machine manufacturer

Another key benefit is the reduction in waste material. Traditional manufacturing processes often generate excess scrap when switching between profiles. However, a double layer forming machine optimizes material usage by ensuring that both layers are processed efficiently, resulting in less waste and a more sustainable operation.

Choosing a Reliable Manufacturer

When searching for a double layer forming machine manufacturer, several factors should be considered to ensure that you select a reliable and competent supplier. First and foremost, look for manufacturers with a strong reputation in the industry. Reviews and testimonials from previous clients can provide insight into their reliability, quality, and customer service.

Additionally, consider a manufacturer’s experience and expertise. Companies with a long-standing history in the field are more likely to have refined their processes and technologies, resulting in superior products. It's also important to assess their range of offerings; a good manufacturer should provide customizable solutions tailored to your specific needs.

Finally, ensure that the manufacturer offers comprehensive support and maintenance services. A reliable double layer forming machine is a significant investment, and having a manufacturer that stands behind their product with ongoing support can give you peace of mind.

Conclusion

The rise of double layer forming machines marks a significant evolution in the manufacturing sector. With their ability to enhance productivity, reduce costs, and minimize waste, they are becoming indispensable for businesses looking to maintain competitiveness in a fast-paced market. As demand increases, selecting a reputable manufacturer who understands your unique needs will be critical in leveraging the full potential of this innovative machinery. By investing in a double layer forming machine, manufacturers are not just purchasing a piece of equipment; they are embracing the future of efficient and flexible production.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025