Leading Manufacturer of Portable Standing Seam Roll Formers for Efficient Metal Roofing Solutions

Exploring Portable Standing Seam Roll Formers A Comprehensive Overview

In the realm of modern construction, the use of metal roofing has gained substantial popularity, owing largely to its durability, aesthetic appeal, and energy efficiency. Among the tools essential for creating metal roofs is the portable standing seam roll former. This equipment offers a range of advantages for contractors and builders, making it an invaluable asset in the roofing industry.

What is a Standing Seam Roll Former?

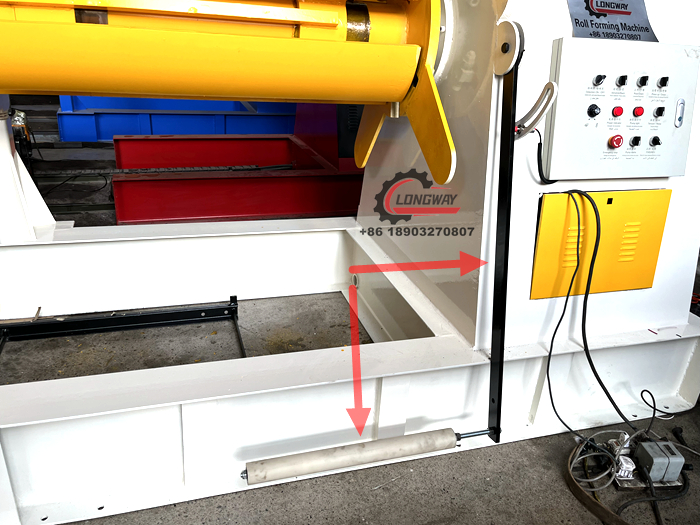

A standing seam roll former is a machine designed to produce standing seam profiles from metal sheets. The standing seam roof system consists of vertical metal panels that are interlocked at the seams, providing an elegant look along with excellent water resistance. The roll former processes flat metal sheets through a series of rollers, shaping the metal into the desired profile while enhancing its structural integrity.

The Portability Advantage

The concept of portability in roll formers signifies that these machines can be easily transported to various job sites. This is especially beneficial for contractors who deal with residential or commercial roofing projects where the logistics of transporting large, heavy equipment can be cumbersome. Portable roll formers are typically designed to be lightweight and compact, ensuring that they can be quickly set up and taken down, leading to increased efficiency on the job site.

Benefits of Using Portable Standing Seam Roll Formers

1. Cost-Effectiveness Hiring external manufacturers to supply metal roofing panels can be expensive. By having a portable standing seam roll former, contractors can produce custom panels on-site, reducing transportation costs and lead times.

2. Customization Each roofing project can have unique specifications. Portable roll formers allow for the customization of panel lengths and profiles right at the job site, offering greater flexibility to meet client preferences.

portable standing seam roll former manufacturer

3. Quality Control By producing panels on-site, contractors maintain greater control over the quality of the materials used. Ensuring proper alignment and seam integrity helps mitigate issues often encountered with pre-manufactured panels.

4. Waste Reduction On-site production allows for better management of materials and reduces waste. Contractors can efficiently use leftover materials from one job for another, promoting sustainable practices in construction.

5. Enhanced Productivity Time is often of the essence in construction projects. With a portable standing seam roll former, the ability to create and install panels in quick succession facilitates faster project completion.

Selecting a Manufacturer

When considering a manufacturer for a portable standing seam roll former, it is crucial to evaluate several factors. Look for a company with a solid reputation for quality and reliability. It's beneficial to identify manufacturers that offer robust customer support and comprehensive training resources, ensuring that your team can operate the machinery efficiently.

Additionally, assess the specifications of the roll former, including the types of materials it can handle, its operational speed, and ease of maintenance. A well-designed machine should require minimal downtime and provide consistent results with every use.

Conclusion

In conclusion, portable standing seam roll formers represent a significant advancement in roofing technology, providing contractors with the tools necessary to enhance efficiency, reduce costs, and ensure a high level of quality in their roofing projects. As more builders recognize the advantages of these versatile machines, the demand for portable standing seam roll formers is expected to grow. Investing in such equipment not only elevates the quality of construction projects but also supports the trend towards fast, flexible, and efficient job site operations.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025