Leading Manufacturer of Galvanized Metal Profile Forming Machines for Precision Construction Solutions

The Role of Galvanized Metal Profiles in Modern Construction

In the ever-evolving landscape of construction and manufacturing, galvanized metal profiles have become increasingly significant. This rise in popularity is largely attributed to their durability, resistance to corrosion, and overall versatility. When we look into the machinery responsible for producing these profiles, specifically the galvanized metal profile forming machine, it becomes clear how technology plays a crucial role in enhancing construction processes.

Understanding Galvanized Metal

Galvanization is the process of applying a protective zinc coating to steel or iron, preventing rusting and prolonging the material's lifespan. This is particularly vital in construction, where structural integrity is paramount. The use of galvanized metal profiles allows architects and builders to design structures that not only meet safety standards but also withstand harsh environmental conditions. From roofing sheets to structural beams, the applications are diverse, making galvanized metal an indispensable material in modern construction.

Importance of Metal Profile Forming Machines

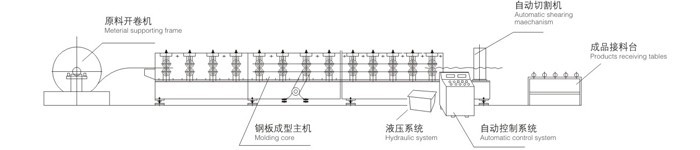

The transition from raw materials to finished products is where metal profile forming machines come into play. These specialized machines are engineered to shape sheets of galvanized metal into various profiles that meet specific construction requirements. They employ advanced forming technologies to ensure precision and consistency during the manufacturing process.

A typical galvanized metal profile forming machine operates by feeding metal sheets through a series of rollers that gradually shape the material into the desired profile. This process is highly automated, ensuring efficiency and minimizing material waste. Manufacturers today are investing in more sophisticated machinery that utilizes computer numerical control (CNC) systems, allowing for customization in production. This capability not only speeds up manufacturing but also enables companies to cater to a diverse range of client needs.

Enhancing Efficiency and Reducing Costs

galvanized metalcon perfiles forming machine company

One of the most significant advantages of using a galvanized metal profile forming machine is the increased efficiency it brings to the production line. By automating the forming process, companies can produce a higher volume of profiles in a shorter time frame. This efficiency translates into cost savings, which can be crucial in competitive markets.

Moreover, the precision offered by modern forming machines reduces the likelihood of errors and waste, ensuring that the final products meet strict quality standards. This reliability is essential for construction projects where subpar materials can lead to structural failure or increased costs down the line.

Sustainability in Construction

Another key consideration in today’s construction industry is sustainability. The use of galvanized metal profiles contributes to eco-friendly building practices. Galvanized steel can be recycled without losing its properties, promoting a circular economy. The longevity of galvanized materials means that buildings require less maintenance and replacement over time, further reducing their environmental impact.

Manufacturers of galvanized metal profile forming machines are also focusing on energy-efficient technologies. Innovations aimed at decreasing power consumption during production help lower the overall carbon footprint associated with construction activities.

Conclusion

In conclusion, galvanized metal profiles, produced through advanced forming technologies, are paving the way for innovative construction solutions. The role of galvanized metal profile forming machines is pivotal, enhancing efficiency, reducing costs, and promoting sustainability within the industry. As we continue to explore new materials and technologies, galvanized metal will undoubtedly remain a vital component in the construction of durable, resilient, and environmentally-friendly structures. With ongoing advancements in forming technologies, the future of galvanized metal profiles looks promising, ensuring that they will remain at the forefront of modern construction practices.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025