High-Quality Keel Roll Forming Machine available for Purchase at Competitive Prices

Introducing the KEEL Roll Forming Machine A Game Changer in Metal Fabrication

In today’s fast-paced manufacturing landscape, the demand for efficient and versatile machinery continues to rise. One such innovation that has caught the attention of industries worldwide is the KEEL roll forming machine. This advanced piece of equipment is designed to streamline the production of steel keels, which are essential components in various applications, ranging from construction to automotive manufacturing. For businesses looking to enhance their production capabilities, the KEEL roll forming machine is a vital investment.

What is a KEEL Roll Forming Machine?

At its core, a KEEL roll forming machine is a type of machinery specifically designed to create metal profiles with a unique shape, often used in the construction of building frameworks, roof trusses, and even interior partitions. The process involves feeding a metal sheet through roller dies that progressively shape the metal into a desired profile. This ensures high precision and uniformity in the final product, significantly reducing material waste when compared to traditional cutting and welding techniques.

Key Features

1. High Efficiency One of the most significant advantages of the KEEL roll forming machine is its high efficiency. Capable of producing large quantities of metal profiles in a short period, the machine operates continuously, minimizing downtime and maximizing output.

2. Versatility The KEEL machine is not limited to a specific type of metal or profile. It can work with various materials, including mild steel, galvanized steel, and aluminum, allowing manufacturers to tailor their production to various projects.

3. Customization Each KEEL roll forming machine can be customized to meet specific production needs. Manufacturers can adjust the machine's settings to create different profiles, making it an invaluable tool for companies that require flexibility in their production lines.

4. Automated Control Systems Modern KEEL machines often come equipped with advanced automation features, including computer numerical control (CNC) systems. This technology allows for easy programming and adjustments, facilitating quick changes between different production runs and ensuring high precision in the final outputs.

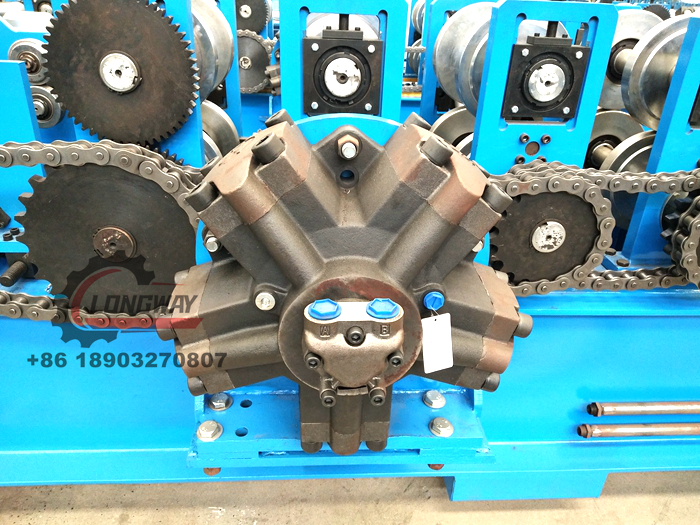

keel roll forming machine for sale

5. Robust Construction Built to withstand the rigors of industrial use, KEEL roll forming machines are made from high-quality materials. Their sturdy construction contributes to their longevity and reliability, making them a worthwhile investment for any manufacturing facility.

Benefits of KEEL Roll Forming Machines

Investing in a KEEL roll forming machine offers multiple benefits for manufacturers

- Cost-Effective Production By minimizing waste and maximizing efficiency, businesses can reduce their overall production costs. This translates to better profit margins and a competitive edge in the market.

- Improved Quality The precision offered by roll forming machines results in high-quality products that meet industry standards, reducing the likelihood of defects and returns.

- Scalability As a business grows, the KEEL roll forming machine can adapt to increased production demands without compromising quality or efficiency.

Conclusion

In conclusion, the KEEL roll forming machine is a vital asset for any business involved in metal fabrication. Its combination of efficiency, versatility, and precision makes it an optimal choice for producing high-quality steel keels and other metal profiles. By investing in this cutting-edge technology, manufacturers can enhance their production processes, reduce costs, and maintain a competitive edge in an increasingly challenging market. As demand for these machines continues to grow, now is the perfect time for businesses to explore the potential of the KEEL roll forming machine and elevate their manufacturing capabilities to new heights.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025