keel roll forming machine

The Importance of Keel Roll Forming Machines in Modern Manufacturing

In the realm of modern manufacturing, the efficiency and precision of production processes are paramount. One of the critical technologies that have emerged to enhance the efficiency of metal fabrication is the keel roll forming machine. These machines are designed to produce a variety of structural shapes, particularly the keel profiles that are essential in various industries, including construction, automotive, and shipbuilding.

A keel roll forming machine operates by gradually bending a continuous strip of metal, typically steel, through a series of rollers to create a desired cross-sectional shape. The term keel refers to the structural member that runs along the bottom of a vessel, providing stability and strength. Similarly, in industrial applications, keel profiles are integral for supporting frameworks and offering structural integrity.

One of the significant advantages of keel roll forming machines is their ability to produce components with high accuracy and repeatability. Traditional methods of shaping metal, such as cutting and welding, often lead to inconsistencies in dimensions and structural weaknesses. In contrast, roll forming maintains a uniform thickness throughout the material and reduces waste by utilizing the entire strip without significant off-cuts. This not only results in cost savings but also contributes to sustainability efforts by minimizing scrap material.

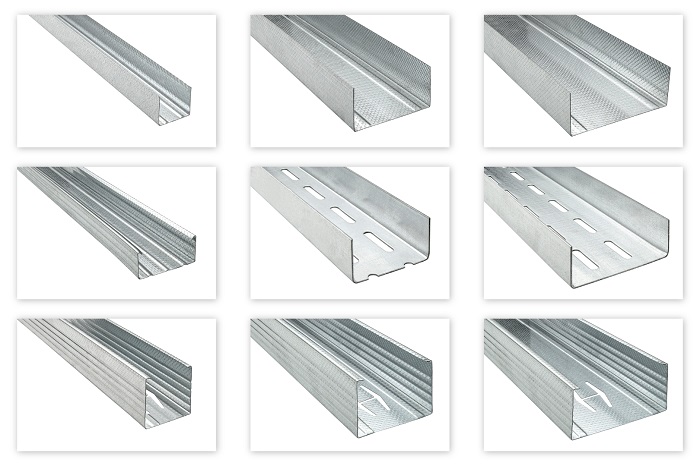

The versatility of keel roll forming machines is another notable feature. They can be customized to produce various profiles tailored to specific applications. For example, modifications in roller design and arrangement can yield different shapes, such as U-shaped, L-shaped, or C-shaped profiles. This adaptability makes keel roll forming machines invaluable for manufacturers looking to diversify their product lines without investing in multiple separate machines.

keel roll forming machine

Additionally, the production speed of keel roll forming machines is impressive. These machines can operate at high speeds, allowing manufacturers to meet tight deadlines and high-demand situations. The continuous nature of the roll forming process means that large quantities of products can be produced in a relatively short time, significantly improving throughput in manufacturing environments.

Moreover, advancements in technology have led to enhanced automation in keel roll forming machines. Modern machines come equipped with computerized controls that enable precise adjustments and monitoring throughout the production process. This not only alleviates the potential for human error but also facilitates real-time quality control, ensuring that each component meets strict industry standards before leaving the production floor.

Furthermore, the incorporation of sensors and data analytics in the operation of keel roll forming machines allows manufacturers to track performance metrics and optimize processes. By analyzing data collected during production, companies can identify inefficiencies and implement corrective measures, ultimately driving continuous improvement in manufacturing practices.

In conclusion, keel roll forming machines represent a significant advancement in the field of metal fabrication, offering unparalleled efficiency, precision, and versatility. Their ability to produce high-quality keel profiles and other structural shapes rapidly and sustainably makes them essential tools for manufacturers across various industries. As technology continues to evolve, we can expect further enhancements in roll forming techniques, pushing the boundaries of what is possible in modern manufacturing. By investing in keel roll forming machinery, companies can not only enhance their productivity but also ensure a competitive edge in an increasingly demanding market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025