keel channel roll forming machine

The Keel Channel Roll Forming Machine Revolutionizing Metal Fabrication

In the landscape of modern manufacturing, the keel channel roll forming machine has emerged as a significant apparatus designed for the efficient production of keel channels and related metal components. This advanced technology not only enhances productivity but also ensures precision, thereby reshaping the processes involved in metal fabrication. In this article, we will delve into the functionality, advantages, and applications of keel channel roll forming machines.

Understanding the Keel Channel Roll Forming Machine

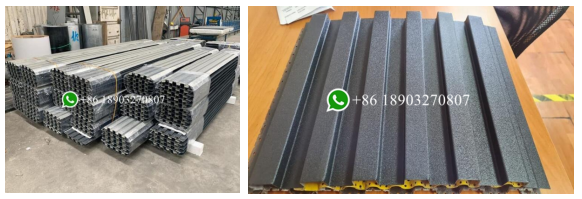

A keel channel roll forming machine is specifically designed to fabricate keel channels, which are structural members widely used in various construction and manufacturing applications. The roll forming process involves feeding a continuous strip of metal through a series of rollers, where it is progressively shaped into a desired profile, such as a keel channel. This method is favored for its efficiency, as it allows for the mass production of uniform channels while minimizing waste.

Typically constructed from high-quality materials, these machines are capable of handling various metals, including steel, aluminum, and galvanized steel. They come equipped with advanced features such as programmable controls, automatic feeding systems, and real-time monitoring, which enhance their usability and efficiency.

Advantages of Using Keel Channel Roll Forming Machines

1. Cost-effectiveness One of the most significant advantages of utilizing a keel channel roll forming machine is the reduction in costs associated with metal processing. The ability to produce larger quantities in a shorter timeframe means that manufacturers can save on labor and material costs while increasing their production capacity.

2. Precision and Consistency Roll forming machines are renowned for their precision. The process ensures that each channel produced maintains consistent dimensions and quality, which is critical in applications where uniformity is essential. This level of accuracy minimizes the need for additional machining processes.

keel channel roll forming machine

3. Versatility The adaptability of keel channel roll forming machines is another notable benefit. They can be adjusted to produce various profiles and sizes, allowing manufacturers to meet diverse customer specifications without the need for separate machinery for each profile.

4. Reduced Waste The continuous formation of metal strips leads to less waste compared to other manufacturing methods. This eco-friendly aspect of roll forming is increasingly important as industries strive to reduce their environmental footprint.

5. Ease of Operation Most modern keel channel roll forming machines are equipped with user-friendly interfaces, making them easy to operate. Additionally, automation features significantly reduce the risk of human error and improve overall safety in the workplace.

Applications of Keel Channel Roll Forming Machines

Keel channel roll forming machines find applications in a variety of industries. In construction, they are frequently used to create a wide range of structural components, including wall studs, track channels, and frames for buildings. Their robustness and durability make them ideal for supporting various loads and ensuring the stability of structures.

In the automotive sector, these machines contribute to the production of parts such as brackets, supports, and chassis components, ensuring vehicles are manufactured to precise specifications. Furthermore, in the manufacturing of appliances and furniture, keel channels serve as structural elements that enhance product stability and design flexibility.

Conclusion

The keel channel roll forming machine is a remarkable innovation in the realm of metal fabrication, offering numerous advantages that cater to modern manufacturing demands. Its ability to produce high-quality, cost-effective, and uniform components makes it an indispensable tool across various industries. As technology continues to advance, the importance of such machines will only grow, paving the way for more efficient and sustainable manufacturing practices. Investing in a keel channel roll forming machine can significantly enhance production capabilities, positioning manufacturers to thrive in a competitive market. Embracing this technology represents a strategic move towards operational excellence and innovation.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025