Iron Sheet Roll Forming Equipment Manufacturing Solutions for Efficient Production

The Evolution and Importance of Iron Sheet Roll Forming Machine Factories

In the realm of industrial manufacturing, the production of iron sheets has become a paramount process, particularly in the construction, automotive, and manufacturing sectors. Central to this production is the iron sheet roll forming machine, a sophisticated piece of machinery that transforms flat steel into various shapes and profiles. As industries strive for efficiency, scalability, and precision, the role of iron sheet roll forming machine factories has gained significant importance.

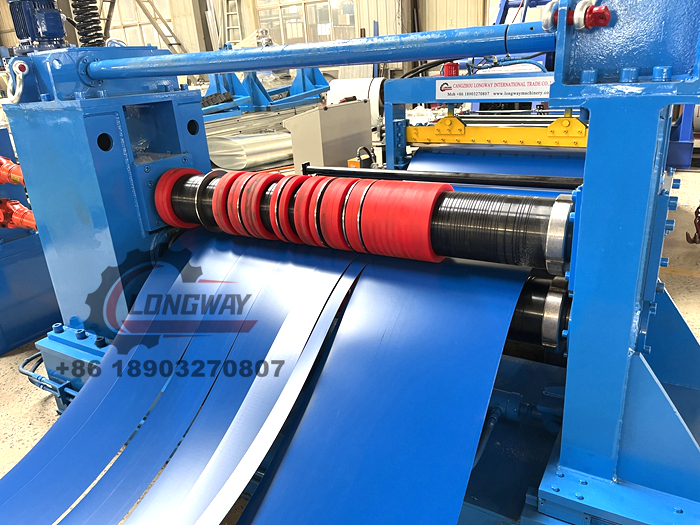

Understanding Roll Forming Technology

Roll forming is a continuous manufacturing process that allows for the shaping of metal sheets into desired profiles. The process begins with feeding flat metal sheets through a series of rollers that progressively shape the material. This method is favored for its ability to produce uniform sections with high accuracy at high speeds, making it ideal for large-scale production.

Iron sheet roll forming machines can produce a wide range of profiles, from simple shapes to complex geometric designs. This versatility makes them integral to the construction of roofing panels, frames, gutters, and many other structural components. As industries evolve and demands increase, the need for advanced roll forming technology continues to grow.

The Role of Factories in Production

Iron sheet roll forming machine factories serve as vital hubs of innovation and production

. These factories are equipped with state-of-the-art machinery and technology capable of producing high-quality rolled iron sheets efficiently. By investing in advanced automation and robotics, these facilities not only enhance production speed but also minimize human error, significantly improving the consistency and quality of the final products.Moreover, factories employ skilled technicians and engineers who ensure that each stage of the manufacturing process meets industry standards. From the selection of raw materials to the final inspection of the finished product, these professionals play an essential role in maintaining quality control.

In addition to producing standard profiles, many roll forming machine factories are equipped to customize designs based on client specifications. This capacity for customization opens up new opportunities for architects and engineers, allowing for innovative designs that were previously unattainable.

iron sheet roll forming machine factory

Sustainable Practices in Manufacturing

As global awareness of environmental issues continues to rise, iron sheet roll forming machine factories are also adapting to sustainable practices. Modern factories focus on minimizing waste by optimizing material usage and recycling scrap metal. Furthermore, many manufacturers are investing in energy-efficient machines that reduce power consumption during production, thus lowering their carbon footprint.

The integration of sustainable practices not only benefits the environment but also enhances the reputation of factories, appealing to a growing base of environmentally-conscious clients. This shift towards sustainability is critical in today's market, where consumers increasingly prefer companies that prioritize eco-friendly practices.

Future Trends in Roll Forming

The future of iron sheet roll forming machine factories is poised for further evolution, driven by technological advancements. With the rise of Industry 4.0, factories are increasingly adopting smart manufacturing technologies such as IoT (Internet of Things), AI (Artificial Intelligence), and big data analytics. These technologies enhance operational efficiency, predictive maintenance, and real-time monitoring, ultimately leading to improved productivity and reduced costs.

Additionally, the integration of 3D printing with roll forming processes is on the horizon, offering unprecedented design capabilities. This fusion could revolutionize the way iron sheets are produced, allowing for more complex and intricate designs while maintaining the efficiency of traditional roll forming.

Conclusion

In summary, iron sheet roll forming machine factories are pivotal to the modern manufacturing landscape. Their ability to produce high-quality, customized iron sheets efficiently positions them as essential players in various industries. By embracing sustainable practices and cutting-edge technologies, these factories are not only meeting current demands but are also paving the way for a more innovative and environmentally responsible future in manufacturing. As the industry continues to evolve, the significance of roll forming machinery will only grow, highlighting the critical role these factories play in shaping the world around us.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025