iron roof sheet making machine

The Iron Roof Sheet Making Machine Revolutionizing Construction

In the world of construction and building materials, the evolution of technology has led to the development of specialized machines that enhance efficiency, durability, and cost-effectiveness. One of the most significant innovations in this field is the iron roof sheet making machine. This machine has transformed the way roofing materials are produced, allowing for greater precision and higher output, while also catering to the increasing demand for robust roofing solutions.

Iron roof sheets have long been a popular choice for both residential and commercial structures due to their strength, longevity, and resistance to harsh weather conditions. Traditional manufacturing methods were often labor-intensive and time-consuming, which made it challenging for manufacturers to keep up with the growing market demands. The introduction of the iron roof sheet making machine has addressed these challenges by streamlining the production process and significantly increasing output capacity.

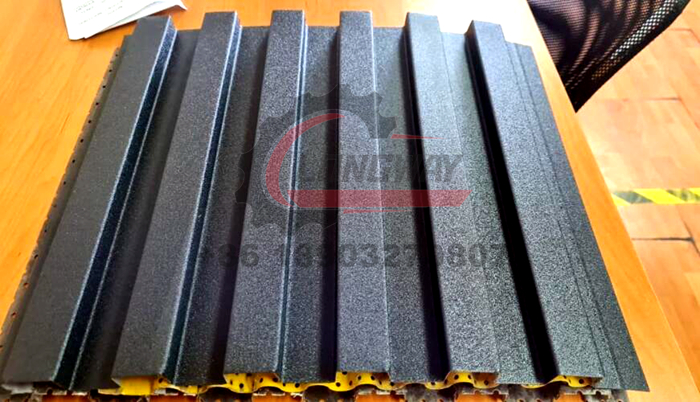

At its core, the iron roof sheet making machine operates on the principle of roll forming. This process involves feeding metal coils through a series of rollers, which gradually shape and mold the material into the desired profile. The machine is equipped with advanced technology that ensures precision in measurements and consistency in product quality. This level of accuracy is crucial for manufacturers to meet the specifications required for modern construction projects.

One of the primary advantages of using an iron roof sheet making machine is its efficiency. The automated processes reduce the need for manual labor, which not only speeds up production but also minimizes the risk of errors that can occur in manual processing. Additionally, these machines can be customized to produce a variety of sheet profiles, catering to different architectural styles and requirements. This versatility allows builders and architects to choose the best roofing solution for their projects.

iron roof sheet making machine

Moreover, the durability of iron roof sheets produced by these machines is unparalleled. Iron, when treated and coated properly, can withstand extreme weather conditions, resist corrosion, and provide long-lasting performance. The machine's ability to create consistent product thickness and finish ensures that each sheet meets high-quality standards, which is essential for maintaining the integrity of buildings.

Cost-effectiveness is another significant factor that makes the iron roof sheet making machine a wise investment for manufacturers. By automating the manufacturing process, companies can reduce labor costs, minimize waste, and improve production timelines. These savings can then be passed on to customers, making iron roof sheets an attractive option for builders looking to stay within budget without compromising on quality.

Furthermore, as the construction industry increasingly focuses on sustainability, the iron roof sheet making machine supports environmentally friendly practices. The use of recyclable materials in the production of iron sheets, combined with efficient manufacturing processes that reduce waste, aligns with the growing demand for sustainable construction solutions. This supports the industry’s transition toward greener practices, appealing to environmentally conscious consumers.

In conclusion, the iron roof sheet making machine has revolutionized the production of roofing materials in the construction industry. Its ability to enhance efficiency, ensure quality, and promote sustainability makes it an essential tool for manufacturers. As the demand for durable and reliable roofing solutions continues to grow, the role of this innovative machine will only become more critical. Embracing such technology not only benefits manufacturers and builders but also contributes to the overall advancement of the construction industry, paving the way for more resilient and sustainable structures in our communities.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025