Efficient Roll Forming Solutions for Insulated Panel Production Machinery

Understanding Insulated Panel Roll Forming Machines A Comprehensive Overview

In the modern construction industry, efficiency and insulation are vital components for creating energy-efficient structures. Among the various technologies that support these goals, insulated panel roll forming machines have emerged as a crucial innovation. These machines are designed to manufacture insulated panels, which are essential in constructing roofs, walls, and facades that offer superior thermal insulation and structural integrity. In this article, we will explore the functionality, benefits, and applications of insulated panel roll forming machines.

What is an Insulated Panel Roll Forming Machine?

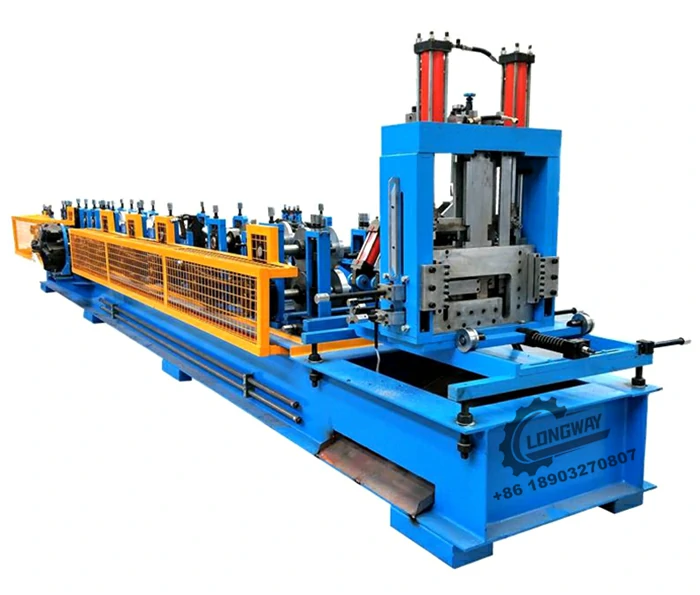

An insulated panel roll forming machine is a specialized piece of equipment used in the production of insulated metal panels. These panels consist of two outer layers, typically made from steel or aluminum, with an insulating core—commonly made from EPS (Expanded Polystyrene), PIR (Polyisocyanurate), or polyurethane—sandwiched between them. The roll forming process involves feeding a metal coil into the machine, where it is shaped into a panel profile and then bonded to the insulation material using advanced adhesives.

The machine operates in a continuous manner, allowing for high-volume production. It typically includes components such as decoilers, roll forming stations, cutting mechanisms, and conveyor systems, ensuring a streamlined workflow from raw material input to finished product output.

The Benefits of Using Insulated Panel Roll Forming Machines

1. Energy Efficiency One of the primary advantages of insulated panels is their ability to minimize heat transfer. This improves the energy efficiency of buildings, reduces heating and cooling costs, and contributes to environmental sustainability. With rising energy prices and increasing awareness of climate change, energy-efficient construction solutions are in high demand.

2. Speed and Efficiency Insulated panel roll forming machines can produce large quantities of panels quickly. The automated nature of the process reduces labor costs and minimizes the potential for human error, resulting in consistent quality in every panel produced.

3. Versatility These machines can be customized to produce panels of various sizes, thicknesses, and profiles, catering to different architectural and structural requirements. This versatility makes them suitable for a wide range of applications, from commercial buildings to industrial facilities and residential homes.

insulated panel roll forming machine

4. Durability and Strength Insulated panels manufactured using roll forming technology are known for their strength. The combined materials offer resistance to environmental factors such as moisture, fire, and pests, ensuring a long lifespan for the building components.

5. Cost-Effectiveness While the initial investment in an insulated panel roll forming machine can be significant, the long-term savings on energy bills and maintenance make it a cost-effective option. Additionally, the efficiency in production reduces overall labor costs.

Applications of Insulated Panel Roll Forming Machines

Insulated panels produced by roll forming machines are widely used across various sectors

- Commercial Construction Many commercial buildings utilize insulated panels for exterior walls and roofing systems. The aesthetic versatility combined with insulation properties enhances both the appearance and energy efficiency of the structure.

- Industrial Facilities Warehouses and manufacturing plants require robust and insulated building materials. Insulated panels are perfect for such applications, providing significant thermal performance while being structurally sound.

- Residential Projects With the growing trend of energy-efficient homes, insulated panels are increasingly popular among builders and architects looking to create sustainable living spaces. They can be utilized for exterior walls, roofs, and even interior partitions.

Conclusion

Insulated panel roll forming machines represent a significant advancement in construction technology, providing an effective solution for producing energy-efficient insulated panels. Their ability to combine speed, durability, and cost-effectiveness makes them indispensable in modern construction practices. As the building industry continues to evolve with a focus on sustainability and efficiency, insulated panel roll forming machines will play a crucial role in shaping the future of architectural design and construction methodologies. Whether constructing commercial buildings, industrial sites, or residential homes, these machines are vital in meeting the increasing demand for energy-efficient building solutions.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025