insulated panel roll forming machine

The Insulated Panel Roll Forming Machine Revolutionizing Construction

In the ever-evolving landscape of modern construction, efficiency and sustainability have become paramount. One of the remarkable innovations that have emerged in this field is the insulated panel roll forming machine. This advanced equipment is designed to produce insulated panels that are not only structurally robust but also energy-efficient, catering to the growing demand for high-performance building materials.

Understanding Insulated Panels

Insulated panels comprise layers of insulating material sandwiched between two structural facings. They are widely used in commercial and industrial building applications due to their excellent thermal performance and quick installation capabilities. These panels provide superior insulation, helping to regulate indoor temperatures and reduce energy costs. The typical applications include wall panels, roof panels, and cold storage facilities, making them an essential component in modern architectural designs.

The Role of the Roll Forming Machine

The insulated panel roll forming machine plays a crucial role in the production of these panels. This sophisticated piece of machinery utilizes a continuous process to shape metal sheets into the desired profiles. By employing a series of rollers, the machine gradually bends the metal into specific shapes while ensuring consistency and precision throughout the manufacturing process. This method is not only efficient but also reduces waste and energy consumption, enhancing the overall sustainability of the construction process.

Key Features of the Insulated Panel Roll Forming Machine

insulated panel roll forming machine

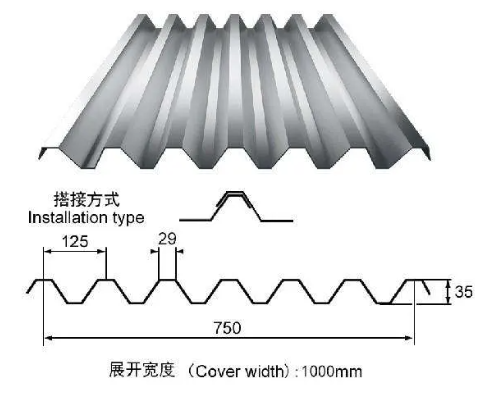

1. Customization One of the standout features of modern insulated panel roll forming machines is their ability to produce panels of varying thicknesses, widths, and profiles. Manufacturers can easily adjust settings to meet specific project requirements, allowing for tailored solutions that fit the unique needs of each construction project.

2. Speed and Efficiency With automation and advanced technology, these machines significantly speed up production times while maintaining high-quality standards. This rapid turnaround is essential in a construction environment where timelines are often tight.

3. Durability and Precision High-quality materials and engineering ensure that these machines can withstand the rigors of continuous use while producing panels with tight tolerances. This precision means fewer defects and a better end product, leading to increased customer satisfaction.

4. Integrated Systems Many modern machines come equipped with integrated systems for cutting, stacking, and handling finished panels, streamlining the entire production process. Automated controls and monitoring systems further enhance operational efficiency.

5. Environmental Benefits By utilizing recycled materials and significantly reducing energy consumption during manufacturing, insulated panel roll forming machines contribute to greener building practices. This aligns with the growing emphasis on sustainability within the construction industry.

Conclusion

The insulated panel roll forming machine represents a significant advancement in the construction sector, combining technology with sustainability to meet the demands of modern building projects. Its ability to produce high-quality insulated panels efficiently and eco-consciously makes it an invaluable asset for manufacturers and builders alike. As the construction industry continues to prioritize energy efficiency and sustainable practices, the insulated panel roll forming machine will undoubtedly play a critical role in shaping the future of building materials and practices.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025