Innovative Solutions for Precision Track Roll Forming Machinery and Their Applications in Modern Industries

Track Roll Forming Machine A Comprehensive Overview

Roll forming is a versatile and efficient manufacturing process used to create long sections of metal with a specific cross-sectional profile. One of the most significant applications of this technology is in the production of track components, particularly in industries such as construction, automotive, and railways. A track roll forming machine is specifically designed to manufacture track sections with precision, ensuring consistency and durability in the final product.

What is a Track Roll Forming Machine?

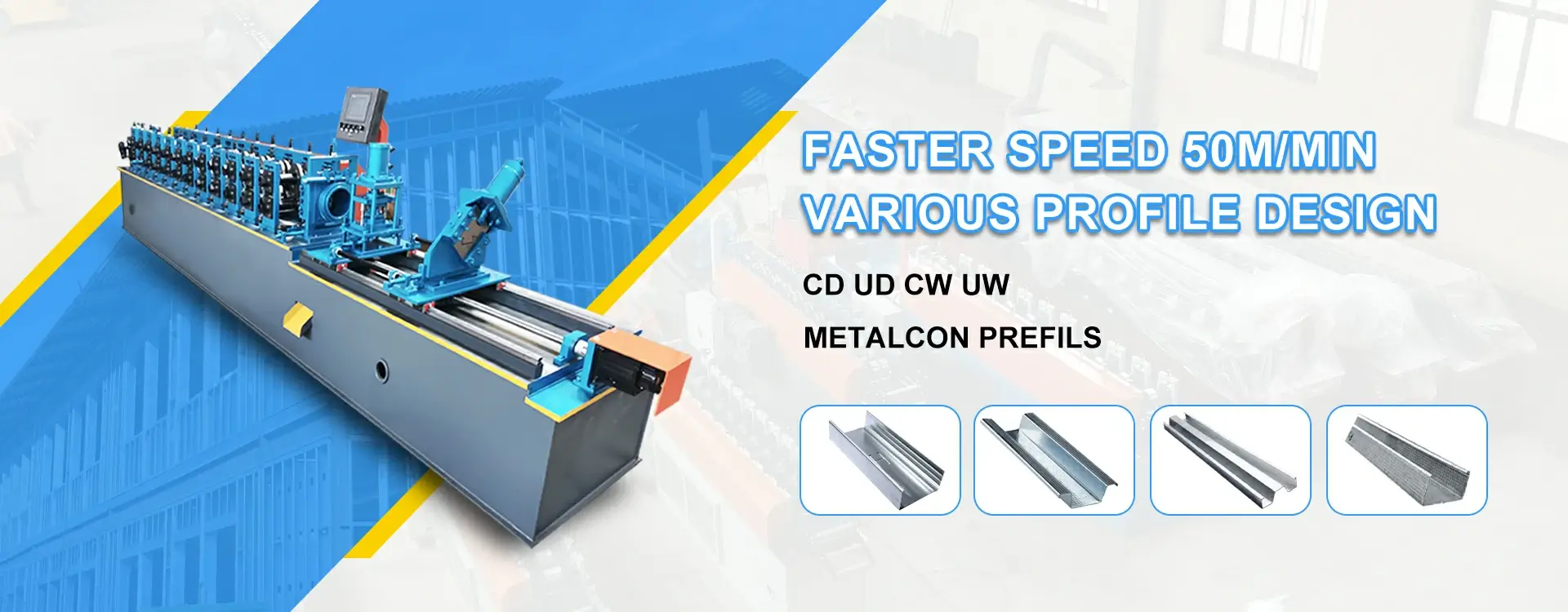

A track roll forming machine is a specialized piece of equipment that shapes metal strips or coils into tracks through a continuous forming process. The machine typically consists of several sets of rollers placed in sequence, each designed to perform a specific shaping function. As the metal strip passes through these rollers, it is gradually transformed into the desired track profile. This method allows for a more streamlined production process, reducing waste and improving overall efficiency.

Key Features and Benefits

1. Precision Manufacturing One of the biggest advantages of using a track roll forming machine is its ability to produce highly accurate and consistent profiles. The rollers are designed with precision-engineered dimensions, ensuring that each track section meets strict specifications.

2. High Production Speed Track roll forming machines operate at high speeds, making them suitable for mass production. With the ability to produce long lengths of track continuously, manufacturers can meet high demand without compromising on quality.

3. Material Versatility These machines can work with various materials, including steel, aluminum, and other metal alloys. This flexibility allows manufacturers to choose the most suitable material for their specific application, whether it’s for structural integrity or weight considerations.

track roll forming machine

4. Reduced Waste The continuous forming process minimizes scrap material, as the machine is designed to use the raw material efficiently. This not only lowers production costs but also aligns with sustainable manufacturing practices.

5. Customizable Designs The track roll forming machine can be adjusted to create a variety of track profiles. Whether manufacturing tracks for rail systems or construction machinery, the machine can be tailored to produce custom designs to meet specific needs.

Applications of Track Roll Forming Machines

Track roll forming machines are widely utilized across different sectors. In the construction industry, they produce tracks for scaffolding and support structures, providing essential strength and stability. In the automotive industry, these machines create tracks for vehicles' undercarriages, enhancing performance and safety. Furthermore, in railway applications, the precision of roll-formed tracks is vital for ensuring smooth operations and safety in train movements.

Maintenance and Operation

To ensure optimal performance, regular maintenance of the track roll forming machine is essential. This includes routine inspections of the rollers, lubrication of moving parts, and calibration to maintain precision dimensions. Proper training for operators is also crucial, as it guarantees that the machine is operated efficiently and safely, reducing the risk of accidents and ensuring product quality.

Conclusion

In summary, track roll forming machines play a critical role in the modern manufacturing landscape. Their capability to produce high-quality, precise, and customizable track profiles makes them indispensable in various industries. As technology advances, these machines are likely to become even more efficient, integrating smart technologies for real-time monitoring and optimization. By adopting track roll forming technology, manufacturers can enhance productivity, reduce costs, and improve product quality, which ultimately contributes to their competitive edge in the market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025