Innovative Solutions for Metal Roofing Machines to Enhance Efficiency and Durability in Construction.

The Rise of Metal Roofing Machines Revolutionizing the Construction Industry

In recent years, the construction industry has witnessed an increasing shift towards more durable and sustainable roofing solutions. Among these innovations is the advent of metal roofing machines, which have transformed the way roofing materials are produced and installed. These machines offer a host of benefits, making them a popular choice for both builders and homeowners alike.

Metal roofing has long been celebrated for its durability, energy efficiency, and aesthetic appeal. However, the traditional methods of manufacturing and installing metal roofs often posed challenges such as high labor costs and extended construction times. This is where metal roofing machines come into play. Designed to produce custom lengths of metal roofing panels on-site, these machines minimize waste and maximize efficiency.

One of the most significant advantages of metal roofing machines is their ability to fabricate roofing panels tailored to the specific dimensions of a building. Traditionally, contractors had to order pre-cut panels, which could lead to excess material and increased costs if not perfectly aligned with the project’s needs. Metal roofing machines eliminate this concern by allowing for on-site production, which not only reduces material waste but also allows for faster turnaround times, as contractors can produce panels as needed.

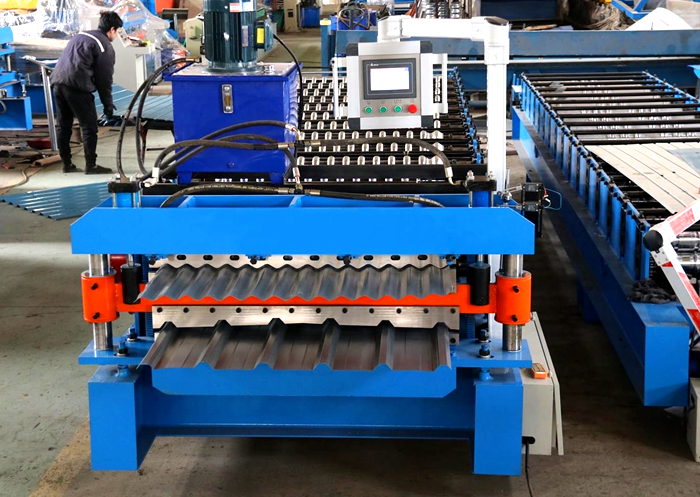

Moreover, modern metal roofing machines are equipped with advanced technology that enhances their functionality

. Many feature computerized controls that enable precise measurements and cuts, ensuring accuracy and consistency in the final product. This level of precision is especially crucial in projects where small differences can lead to significant issues in installation. With these machines, contractors can achieve a level of reliability that enhances the overall quality of the roof.metal roofing machine

Another noteworthy benefit is the versatility of metal roofing machines. They can be adjusted to produce various profiles, including standing seam, corrugated, and tile-style roofing panels. This flexibility allows contractors to respond to diverse customer preferences and architectural demands without the need for multiple machines or extensive setup changes. Consequently, these machines empower construction teams to take on a wider range of projects, from residential homes to commercial buildings.

Energy efficiency is a growing concern in the construction industry, and metal roofing machines can contribute positively to this aspect. Metal roofs are highly reflective, capable of reducing heat absorption and cooling costs. By producing custom-fit panels on-site, contractors can ensure that these energy-efficient materials are used effectively, minimizing gaps and promoting better insulation in buildings.

Furthermore, the ease of use associated with modern metal roofing machines has led to a decrease in skilled labor dependency. While traditional roofing requires highly skilled workers to handle complex installation procedures, the intuitive designs of contemporary machines can allow less experienced crew members to operate them with proper training. This democratization of technology helps to address labor shortages in the construction industry while maintaining high standards of workmanship.

In conclusion, metal roofing machines have emerged as game-changers in the construction sector, offering advantages that go beyond mere convenience. By enabling precise, on-site production of custom roofing panels, these machines enhance efficiency, reduce waste, and support the fabrication of energy-efficient roofs. As the industry continues to evolve, embracing innovation and sustainability, metal roofing machines will undoubtedly play a pivotal role in shaping the future of roofing solutions. Whether for residential projects or commercial undertakings, the impact of this technology is set to be profound, paving the way for a new era of construction excellence.