Innovative Solutions for Door Frame Formation Machinery by Leading Manufacturers in the Industry

The Evolution of Door Frame Forming Machines A Key to Efficient Manufacturing

In the ever-evolving world of manufacturing, precision and efficiency have become paramount. One critical segment of this industry is the production of door frames, which serve as vital structural components in residential and commercial buildings. As demand for these products rises, so does the need for advanced machinery. This is where door frame forming machines come into play, and their manufacturers are at the forefront of this innovation.

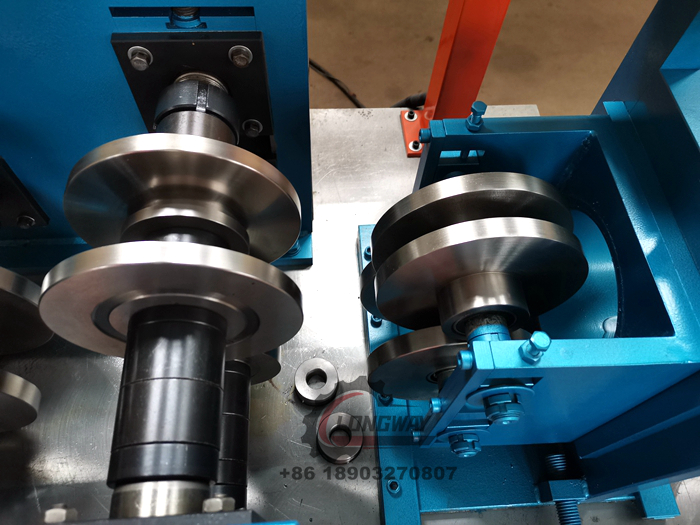

Door frame forming machines are specialized pieces of equipment designed to create door frames from various materials, typically steel, aluminum, or wood. These machines automate the forming process, allowing for faster production rates, consistent quality, and reduced labor costs. Manufacturers of these machines are continuously improving their designs, integrating new technologies to meet the evolving needs of the market.

One of the significant advancements in door frame forming machines is the incorporation of computer numerical control (CNC) technology. This technology allows for precise control over the forming process, enabling manufacturers to produce custom door frames with intricate designs and specifications quickly. The use of CNC technology not only boosts productivity but also enhances the accuracy of the final product, minimizing waste and reducing production costs.

Moreover, advancements in materials and design have led to the development of more robust and energy-efficient machinery. Modern door frame forming machines are built with high-quality components that ensure longevity and reduce maintenance costs. Manufacturers are increasingly focusing on eco-friendly practices, promoting machines that utilize sustainable materials and consume less energy in their operation.

door frame forming machine manufacturer

Another trend in the manufacturing of door frame forming machines is the emphasis on automation and smart technology. The integration of sensors and IoT (Internet of Things) connectivity enables manufacturers to monitor equipment performance in real-time, allowing for predictive maintenance and minimizing downtime. This smart technology provides valuable data analytics, helping manufacturers make informed decisions about production schedules and inventory management.

The competitive landscape of door frame forming machine manufacturers is diverse, with companies ranging from small niche providers to large-scale, globally recognized brands. Each manufacturer brings unique offerings to the table, focusing on different aspects such as customization options, speed, technology integration, and after-sales support. This competition drives innovation, pushing manufacturers to continuously refine their products and expand their capabilities.

As the construction industry grows, the demand for door frames is expected to rise, particularly in emerging markets where urbanization is rapid. Door frame forming machine manufacturers must adapt to this growing market by offering scalable solutions that cater to the needs of clients across various sectors. For instance, integrating modular designs in machinery can provide manufacturers with the flexibility to produce a range of door frame sizes and styles without the need for significant retooling.

In conclusion, the role of door frame forming machine manufacturers is crucial in the modern manufacturing landscape. By embracing technological advancements, focusing on sustainability, and promoting innovation, these manufacturers are not only improving production capabilities but are also contributing to the overall advancement of the construction industry. The future is bright for door frame forming machines, as they evolve to meet the challenges and opportunities presented by a rapidly changing world. As we look ahead, it is clear that the synergy between manufacturing, technology, and sustainability will define the next generation of door frame production.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025