Innovative Roof Curving Machines for Enhanced Roofing Solutions in Modern Construction Industries

Understanding Roof Curving Machine Factories

In the world of construction, particularly in the metal roofing sector, the roof curving machine has emerged as an essential tool for manufacturing roof sheets that require custom curves and shapes. These machines have transformed the way roofing materials are produced, offering higher precision, efficiency, and versatility. Roof curving machine factories play a vital role in this process, facilitating the production of equipment that meets the diverse needs of modern architecture.

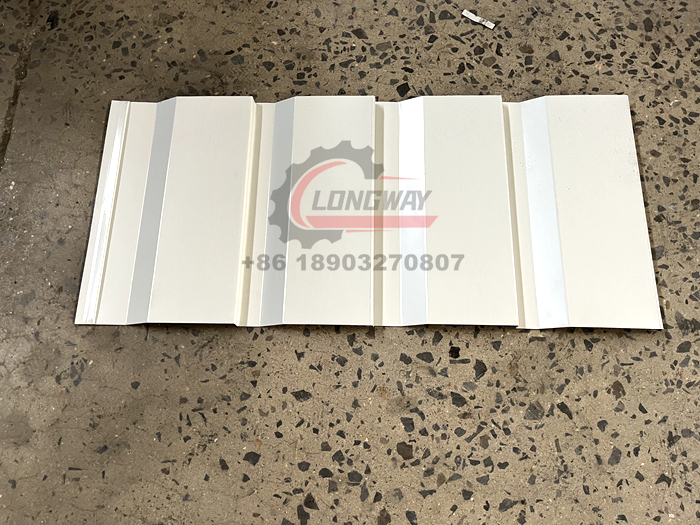

Roof curving machines are designed to alter the shape of metal sheets, enabling them to be bent or curved to the desired specifications. This capability is particularly important for structures that have unique designs, such as sports arenas, auditoriums, or commercial buildings that require aesthetic appeal and functional performance. The curving process ensures that the roofing materials fit perfectly, reducing waste and enhancing the overall quality of the finished project.

The manufacturing of roof curving machines involves a complex interplay of engineering and technology. Factories dedicated to producing these machines invest significantly in research and development to stay ahead in a competitive market. They utilize advanced technologies, such as computer numerical control (CNC), to ensure precision in bending operations. CNC technology allows operators to input specifications directly into a computer, which then controls the machine with remarkable accuracy.

A typical roof curving machine factory will have various departments, including design, assembly, and quality control. The design team is tasked with creating innovative machines that can handle a range of materials and thicknesses while ensuring user-friendliness. Assembly lines are equipped with skilled workers who put together the intricate components of each machine, from the frame to the hydraulic systems that power the bending process.

roof curving machine factories

Quality control is a crucial aspect of the production in a roof curving machine factory. With rigorous testing procedures, manufacturers ensure that each machine can withstand the demands of industrial use. They conduct stress tests, functionality tests, and routine inspections to maintain a high standard. This commitment to quality not only enhances the machine's reliability but also solidifies the factory's reputation in the industry.

In recent years, there has been an increasing demand for environmentally friendly manufacturing processes. Roof curving machine factories are responding to this trend by implementing sustainable practices in their production lines. This includes using recyclable materials in machine components and adopting energy-efficient technologies to reduce carbon footprints. Customers are becoming more conscious of their purchasing decisions, favoring suppliers who prioritize sustainability alongside quality.

Moreover, the global market for roofing materials is expanding, driven by urbanization and the need for modern infrastructure. Roof curving machine factories are well-positioned to capitalize on this growth, offering customized solutions to international clients. By embracing globalization, many factories are also exploring export opportunities, contributing to the global supply chain for roofing equipment.

In addition to manufacturing, roof curving machine factories often provide training and support services to ensure their customers can maximize the use of their machines. Understanding the intricacies of operating complex machinery is vital for avoiding errors and ensuring longevity. Through workshops and one-on-one training sessions, these factories help clients develop their skills, resulting in more efficient operations.

In conclusion, roof curving machine factories are crucial players in the construction industry, enabling the production of innovative roofing solutions tailored to meet diverse architectural needs. Their emphasis on advanced technology, quality assurance, sustainability, and customer support positions them as indispensable partners in the evolution of modern roofing. As the market continues to grow, these factories will undoubtedly play a pivotal role in shaping the future of architecture and construction.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025