Innovative Roll Forming Machine Solutions for Efficient Metal Fabrication and Precision Engineering Processes

The Roll Forming Machine Principles and Applications

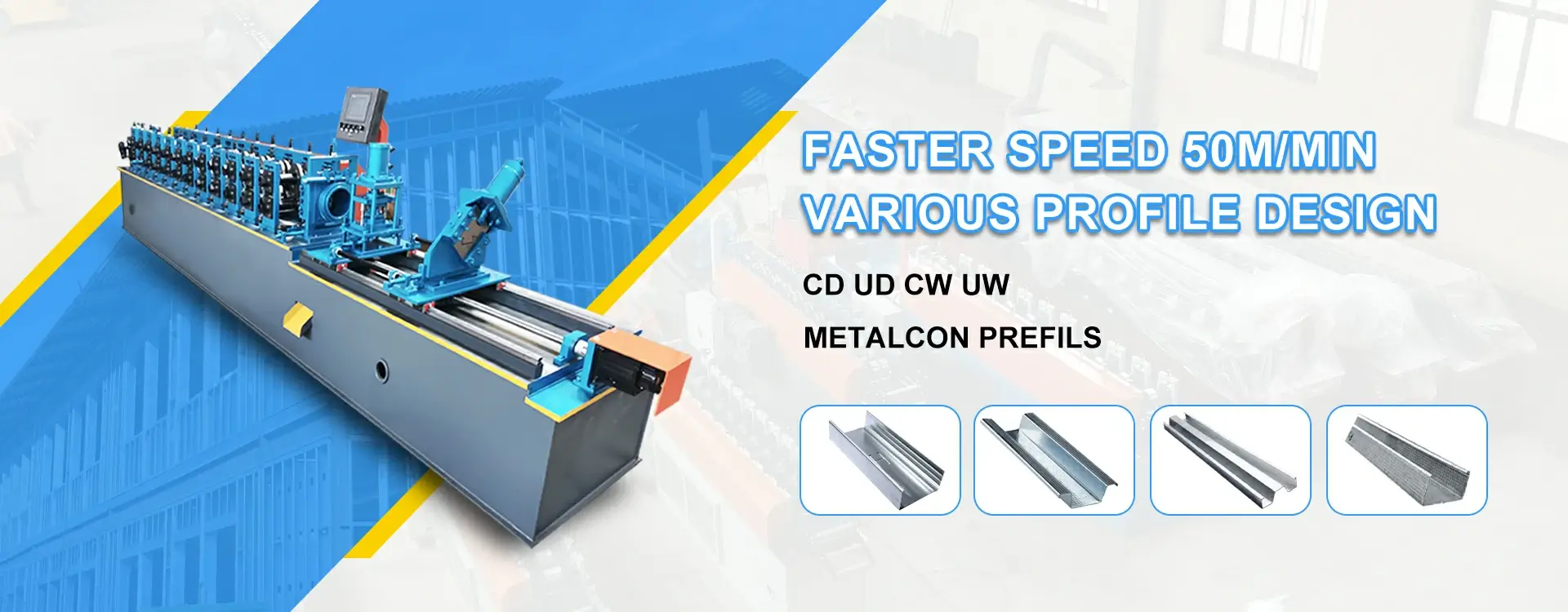

Roll forming is a highly efficient manufacturing process that turns flat metal strip or sheet into desired cross-sectional shapes using a series of contoured rolls. The equipment primarily responsible for this operation is known as the roll forming machine. This machine is a crucial component in industries that require consistent shapes and profiles, like construction, automotive, and appliance manufacturing.

At its core, the roll forming process involves feeding a continuous strip of metal through a series of rollers, which gradually shape it into the desired form. The machine's operational principle is relatively straightforward but highly effective. The first roller in the set, known as the entry roller, guides the flat metal strip into the subsequent rollers, each designed to impart specific bends or curves. As the strip moves through the machine, each roller alters the shape incrementally until the final profile is achieved.

One of the main advantages of roll forming machines is their ability to produce long lengths of metal shape with high dimensional accuracy and repeatability. This characteristic is essential for industries where precise specifications are mandatory. The process can handle various materials, including steel, aluminum, copper, and even plastics, making it versatile for different applications. The continuous nature of the operation also means that manufacturers can produce large quantities of components efficiently, which is often more cost-effective than other forming methods.

Modern roll forming machines are equipped with advanced technology that enhances their functionality

. Many machines today utilize computer numerically controlled (CNC) systems that allow for quick adjustments and alterations in the production process. This capability means that manufacturers can switch between product designs with minimal downtime, improving operational efficiency and adaptability to market demands.roll forming machine

The applications of roll forming machines are vast. In the construction industry, they are used to create a variety of products, including roofing panels, gutters, and purlins. These components are critical in building structures and require both strength and longevity, which roll forming techniques provide. In the automotive sector, roll-formed parts are ubiquitous, used for chassis components, structural beams, and more. Their lightweight and durable properties contribute to better fuel efficiency for vehicles, aligning with modern environmental goals.

Another significant application is in the appliance sector, where manufacturers rely on roll forming to produce brackets, frames, and shelves. The consistency and precision of roll-formed parts are essential in ensuring that end products fit together seamlessly in the assembly process.

Despite the many advantages of roll forming machines, some considerations must be acknowledged. The initial setup costs can be relatively high, especially for custom tooling required for unique shapes. However, these costs are typically offset by the efficiencies gained during mass production. Additionally, while the process is excellent for producing straight sections, creating intricate shapes may require additional stations or secondary processes like welding or machining.

In conclusion, roll forming machines represent a key technological advancement in metal forming processes. Their efficiency, precision, and versatility make them invaluable in various industries, from construction to automotive manufacturing. As technology continues to evolve, the capabilities of roll forming machines will likely expand, providing even more opportunities for innovation and efficiency in metal fabrication. By understanding and leveraging these machines, manufacturers can meet the growing demands for high-quality, precision-engineered components in today's competitive market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025