Innovative Machines Transforming the Production Process of Durable Metal Roofing Solutions

The Rise of Machine Technology in Metal Roofing Production

In the construction industry, the demand for durable and versatile building materials has led to the increasing popularity of metal roofing. This trend has prompted the evolution of production methods, particularly the integration of advanced machinery to make the manufacturing process more efficient. The modern machinery used in metal roofing production represents a significant leap forward, combining precision engineering with the latest technological advancements.

Traditionally, metal roofing was produced using manual processes that required skilled labor and considerable time investment. However, as the demand for metal roofs has surged, driven by their longevity, energy efficiency, and aesthetic appeal, manufacturers have turned to automation. Machines designed specifically for metal roofing have transformed the production landscape, allowing companies to meet heightened demand without sacrificing quality.

The Rise of Machine Technology in Metal Roofing Production

Additionally, these machines can be customized to produce a variety of roofing styles, including standing seam, corrugated, and interlocking panels, catering to a wide range of architectural preferences. The flexibility provided by modern machinery allows manufacturers to innovate and respond to market trends more quickly than ever before.

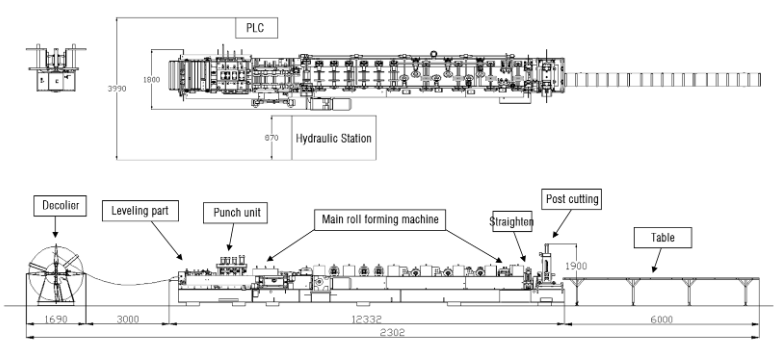

machine to make metal roofing

Another notable development in metal roofing production machinery is the incorporation of Computer Numerical Control (CNC) technology. CNC machines enhance precision and efficiency by automating cutting and shaping processes based on digital designs. This technology minimizes human error and drastically reduces production time. With CNC capabilities, manufacturers can create intricate designs and tight tolerances that would be challenging to achieve through manual methods.

Moreover, automation in metal roofing production extends beyond the forming and cutting processes. Automated handling systems have been integrated to streamline the logistics of material movement. These systems can lift, maneuver, and stack heavy metal panels with ease, reducing the risk of injury to workers and increasing overall productivity. The combination of automated handling with advanced production machinery ensures a smooth workflow from the initial stages of metal preparation to the final packaging of the roofing products.

The sustainability aspect of metal roofing is also enhanced through modern machinery. Many of the machines are designed to minimize waste by optimizing material usage. Scrap metal can be reduced significantly during the production process, which not only cuts costs but also aligns with environmentally friendly practices in the construction sector. Furthermore, metal roofing materials are often made from recycled content, contributing to a reduction in the carbon footprint associated with traditional roofing products.

In conclusion, the evolution of machinery in the metal roofing industry marks a pivotal shift towards efficiency, precision, and sustainability. The integration of advanced technologies like roll-forming and CNC machining has transformed how metal roofs are produced, making it possible to meet growing demands while ensuring high standards of quality. As the construction industry continues to evolve, the role of machinery in metal roofing production will undoubtedly expand, paving the way for even more innovative solutions that will benefit manufacturers, builders, and consumers alike. With ongoing advancements in technology, the future of metal roofing looks promising, poised to redefine standards in durability and design.

-

the-role-of-hydraulic-systems-in-sheet-metal-slittersNewsAug.23, 2025

-

customization-options-in-metal-deck-roll-forming-machinesNewsAug.23, 2025

-

safety-tips-when-using-a-gutter-making-machineNewsAug.23, 2025

-

key-components-of-a-c-purlin-machine-explainedNewsAug.23, 2025

-

maintenance-tips-for-a-steel-angle-roll-forming-machineNewsAug.23, 2025

-

portable-metal-roofing-machine-applications-in-remote-constructionNewsAug.23, 2025

-

Roof Panel MachineNewsAug.18, 2025