Cost of IBR Sheet Making Machines from Various Manufacturers

Understanding the Pricing of IBR Sheet Making Machines Factories and Market Trends

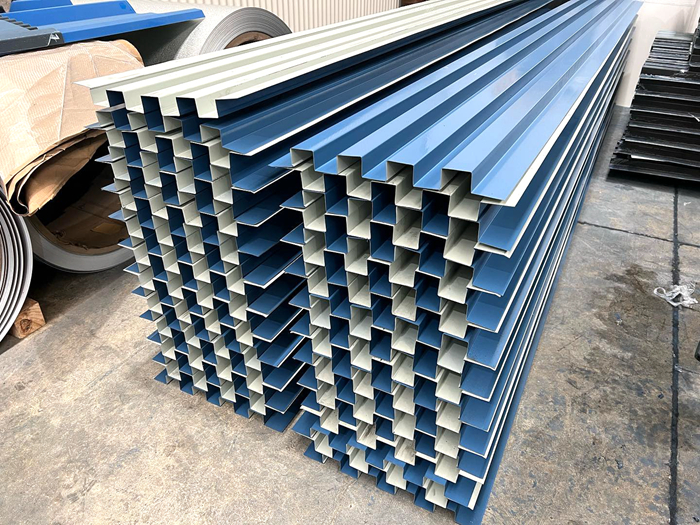

In the industrial sector, the IBR (Inverted Box Rib) sheet is highly valued for its durability and versatility in various applications, including roofing and wall cladding. The production of IBR sheets requires specialized machinery known as IBR sheet making machines. These machines play a crucial role in transforming raw materials into high-quality roofing sheets that are used in construction and other industries. Understanding the pricing of these machines and the factors that influence costs is essential for businesses looking to invest in them.

Factors Influencing the Price of IBR Sheet Making Machines

1. Machine Specifications One of the primary factors affecting the price of IBR sheet making machines is their specifications. Machines come in different capacities, sizes, and features. For instance, a fully automated machine with advanced technology will typically cost more than a semi-automatic version. Buyers should assess their production needs to find a machine that balances efficiency and affordability.

2. Material Quality The durability and performance of a machine are heavily dependent on the quality of the materials used in its construction. High-quality steel and components not only enhance the machine's longevity but also its operational efficiency. While machines made from superior materials may have a higher upfront cost, they often result in lower maintenance costs and extended service life, justifying the investment in the long term.

3. Manufacturing Process The technology and processes employed by the manufacturer in producing the IBR sheet making machines can significantly influence prices. Factories that utilize advanced manufacturing techniques, such as CNC machining and precision engineering, tend to produce higher-quality machines, which may come at a premium price. However, such investments usually lead to better performance and lower error rates during production.

4. Brand Reputation Established brands with a reputation for reliability and quality often charge higher prices for their machinery. This is due to the assurance of better engineering, customer service, and availability of spare parts. Newer or lesser-known brands may offer lower prices as they try to penetrate the market, but they may not always be able to match the quality or support provided by more reputable manufacturers.

ibr sheet making machine price factories

5. Customization Options Many factories offer customization options tailored to specific production needs, which can also affect pricing. Clients looking for specialized features or modifications may face higher costs due to the additional engineering and labor involved in producing a bespoke machine. It's essential for businesses to determine whether custom features are essential for their production process to avoid unnecessary expenditure.

Market Trends and Economic Factors

The global market for IBR sheet making machines is also influenced by economic conditions and industry demands. In regions experiencing rapid construction growth, the demand for IBR sheets—and consequently the machines that make them—tends to increase. Manufacturers in these areas may raise prices due to heightened demand amidst supply constraints.

Additionally, fluctuations in raw material prices, such as steel, can impact the overall cost of production for machinery manufacturers. Therefore, it is crucial for buyers to stay informed about market trends in raw materials and economic conditions that may affect prices.

Conclusion

Investing in an IBR sheet making machine is a significant decision for any business involved in roofing and construction. Understanding the various factors that influence the pricing of these machines can help potential buyers make informed decisions, ensuring that they select a machine that meets their production needs without exceeding their budget. By considering specifications, material quality, manufacturing processes, brand reputation, and customization options, companies can navigate the market more effectively. Ultimately, a well-chosen IBR sheet making machine can enhance production efficiency, leading to increased profitability and success in the competitive construction industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025